A purification system combining dry method net and water column method

A technology of purification system and water column, which is applied in the field of purification system, can solve the problems that the dust removal and purification system cannot meet the emission requirements, the dust removal and purification method is defective, and the purification effect is not ideal, so as to achieve good dust removal effect, low maintenance cost and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

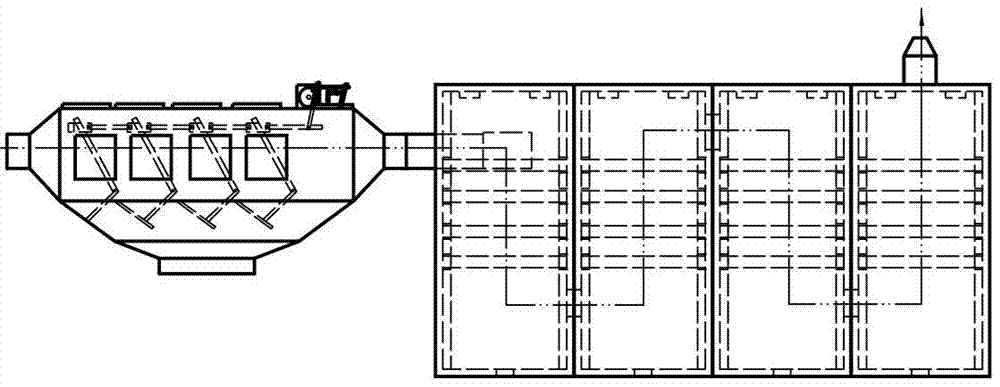

[0036] Such as figure 1 , a purification system combining dry screen and water column method, which is composed of multi-stage dry screen dust collector and water column purifier.

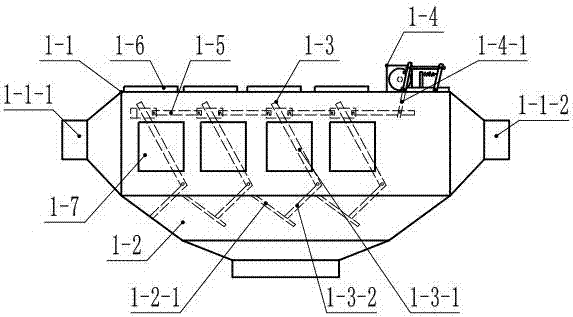

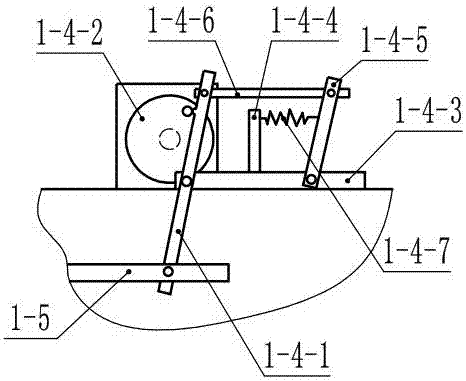

[0037] Such as figure 2 , the multi-stage dry-process screen filter includes a housing 1-1 and a funnel 1-2 arranged below the housing 1-1;

[0038]The housing 1-1 has a dust removal air passage part, an inlet 1-1-1 opened at the front end of the dust removal air passage part and an outlet 1-1-2 opened at the rear end of the dust removal air passage part; the dust removal air passage part is composed of A set of dedusting air passages is formed, or the dedusting air passage part is composed of two groups of dedusting air passages connected in parallel, the left air passage and the right air passage, and a switching device is provided in the inlet 1-1-1 so that the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com