Dust removal device for flexible manufacturing system

A technology of flexible manufacturing system and dust removal device, applied in combination device, separation method, dispersed particle separation, etc., can solve problems such as health hazards of workers, influence on workpiece processing process, pollution of surrounding environment, etc., and achieve good dust removal and purification effect and work Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

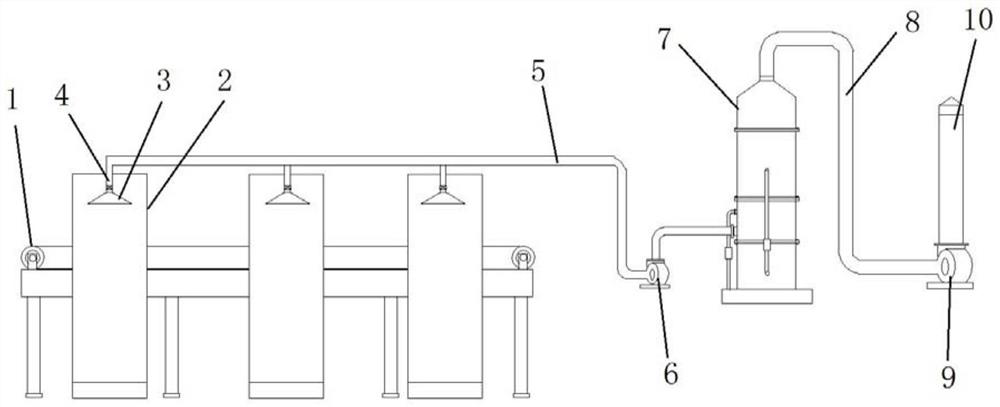

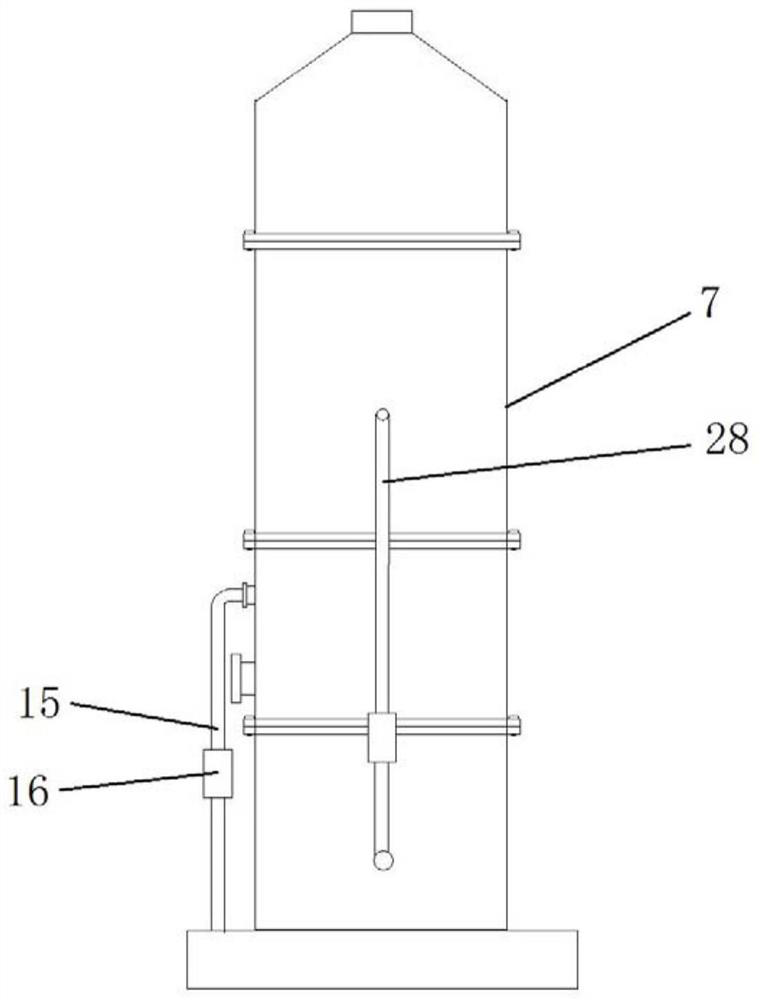

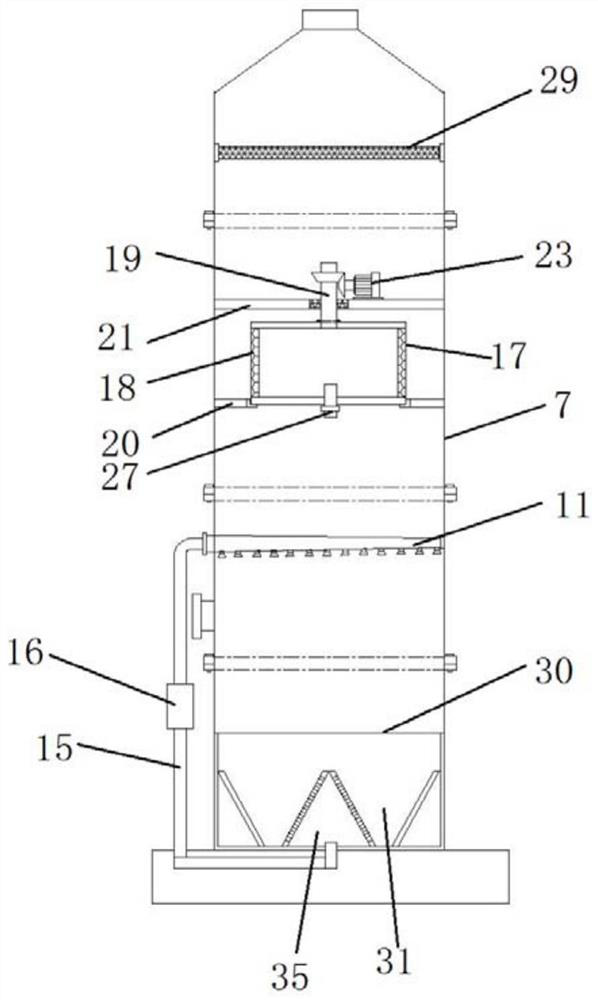

[0032] The embodiment of the present invention discloses a dust removal device for a flexible manufacturing system, such as Figure 1 to Figure 3 As shown, the flexible manufacturing system includes a conveying device 1, a plurality of grasping devices and a plurality of processing chambers 2. The outer side of the conveying device 1 is sequentially provided with a plurality of grasping devices along the conveying direction, and one side of the grasping device is correspondingly provided with a processing chamber. 2. The grabbing device is used to grab the workpiece and can reciprocate between the processing chamber 2 and the conveying device 1. It can adopt the manipulator in the prior art, and the conveying device 1 can adopt the conveying assembly with the conveying function in the prior art , such as a conveyor belt, which is linear, O-shaped or L-shaped; the dust removal device includes an air collection hood 3, an air extraction branch 4, an exhaust fan 6, an air extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com