Efficient biogas slurry and fresh enzyme organic fertilizer and preparation technology thereof

A preparation process, fresh enzyme technology, applied in nitrogen fertilizer, fertilization equipment, fertilizer mixture, etc., can solve the problems of large amount of biogas slurry fertilizer per mu, underdeveloped crop root system, no fruit aroma, etc., to increase the volume of bacteria, improve Acidification of the soil is fast and beneficial to the development of crop roots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

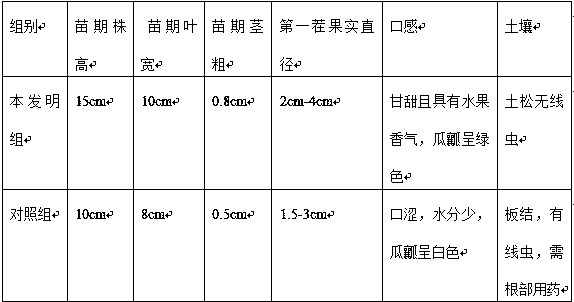

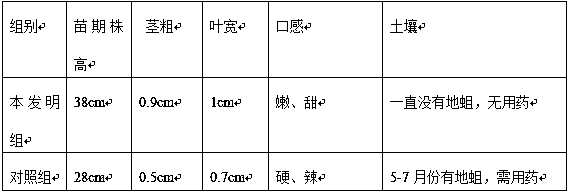

Examples

Embodiment 1

[0037] A biogas slurry fresh enzyme high-efficiency organic fertilizer of the present embodiment comprises the following raw materials in parts by weight: 100 parts of biogas slurry, 0.1 part of puree liquor, 0.5-1 part of fruit enzyme, 0.5-1 jin of brown sugar, compound enzyme probiotic powder 0.02-0.1 part;

[0038] Among them, the degree of puree liquor is above 52°;

[0039] The compound enzyme probiotic powder used is Binboli brand compound enzyme probiotic powder produced by Nanjing Tongrentang Technology Co., Ltd.;

[0040] Fruit enzymes are fermented from at least six substances in apples, kiwis, wolfberries, chrysanthemums, blueberries, grapes, bananas, pineapples, peaches, pears, and dragon fruits.

Embodiment 2

[0042] The difference between the present embodiment and embodiment 1 is that the fruit enzyme also includes Artemisia argyi.

Embodiment 3

[0044] The preparation technology of a kind of biogas slurry fresh ferment high-efficiency organic fertilizer of this implementation comprises the following steps:

[0045] 1. Collect wet garbage in daily life, human and / or animal excrement, water for washing dishes, and leftovers, and transport them to the biogas digester for fermentation for 20-30 days to form biogas slurry and biogas residue;

[0046] 2. Expose the biogas slurry and biogas residue in a sun shed at 30-50°C for 3-5 months;

[0047] 3. Separation of biogas residue and biogas slurry, biogas residue is used for land fertilizer, and biogas slurry is used for liquid fertilizer;

[0048] 4. Take 100 parts of biogas slurry and put it in the spare pool, add 0.1 part of puree white wine, stir evenly, add 1 part of garlic onion enzyme, stir well, let it stand for 24 hours, not only for secondary sterilization, but also to promote hair roots and puree Liquor contains yeast, which can reproduce a large number of yeast a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com