Treatment process of VOCs exhaust gas

A treatment process and tail gas treatment technology, applied in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of VOCs purification efficiency reduction, energy consumption reduction, etc., to reduce consumption, reduce operating costs, and improve purification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

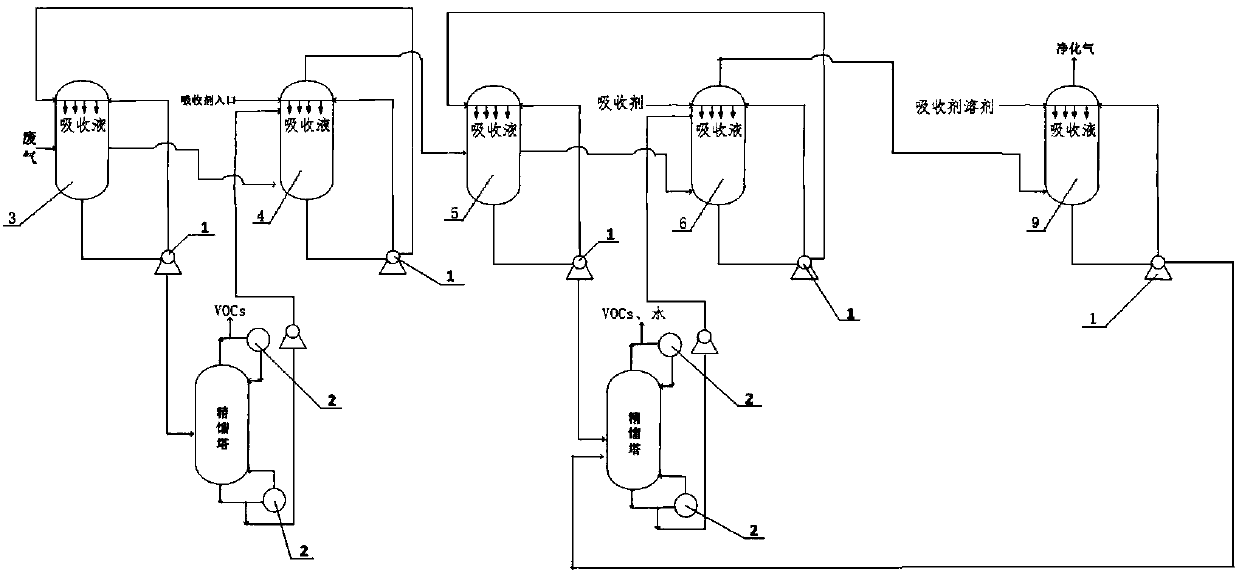

[0040] use as figure 1 The VOCs exhaust gas treatment process shown has a concentration of 11500mg / m for a chemical company 3 of dichloromethane and a concentration of 11500mg / m 3 The mixed waste gas of acetone (the air volume is 800m 3 / h) for processing, the specific process is as follows:

[0041] In this embodiment, VOCs specifically refer to dichloromethane and acetone.

[0042] The exhaust gas treatment process containing dichloromethane and acetone in this embodiment includes a water-soluble VOCs removal step, a water-insoluble VOCs removal step, and an exhaust gas treatment step. In this embodiment, the water-soluble VOCs removal step refers to the water washing step, and the water-insoluble VOCs removal step The step refers to the oil washing step, wherein the water washing step includes two waste gas absorption units connected in series, that is, the water washing head end absorption tower 3 and the water washing secondary absorption tower 4, and the oil washing s...

Embodiment 2

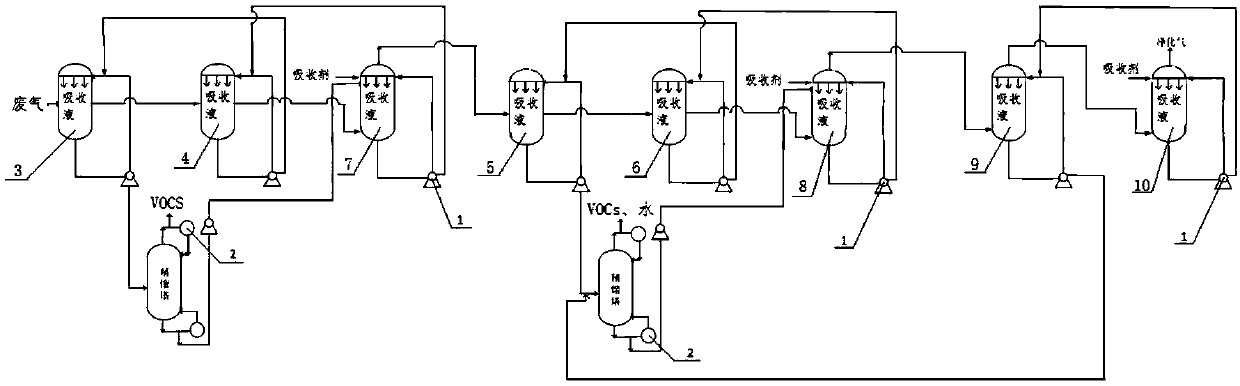

[0052] use as figure 2 The VOCs waste gas treatment process shown has a concentration of 80,000 mg / m for a chemical company 3 of xylene and a concentration of 81000mg / m 3 The mixed exhaust gas (air volume is 1200m 3 / h) for processing, the specific process is as follows:

[0053] In this embodiment, VOCs specifically refer to xylene and acetone.

[0054] In this embodiment, the exhaust gas treatment process containing xylene and acetone includes a water-soluble VOCs removal step, a water-insoluble VOCs removal step, and an exhaust gas treatment step. In this embodiment, the water-soluble VOCs removal step refers to the water washing step, and the water-insoluble VOCs removal step Refers to the oil washing step, wherein the water washing step includes three waste gas absorption units connected in series, namely the water washing head-end absorption tower 3, the water washing secondary absorption tower 4 and the water washing tertiary absorption tower 7, and the oil washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com