Method for preparing composite interlayer coating film on surface of engineering plastics

A technology of engineering plastics and composite coating, which is applied to the surface coating liquid device, special surface, pretreatment surface, etc., can solve the problems of lack of metal texture, large amount of metal consumption, large water and energy consumption, etc., to achieve The surface is hard and smooth, the metal consumption is small, and the effect of improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

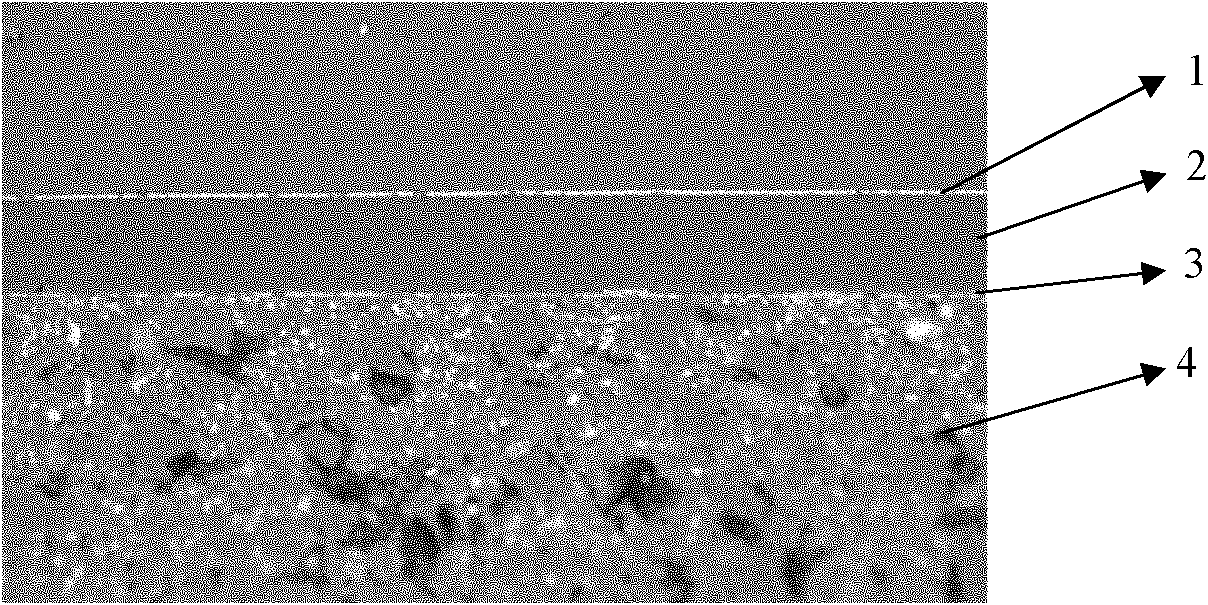

Image

Examples

Embodiment 1

[0029] Embodiment 1 Example of chrome plating of a PC / ABS mirror case

[0030] 1) Send the PC / ABS injection molding blank into the PVD furnace for plasma source glow cleaning and activation (conditions are current 0.3A, bias voltage 100V, argon flow rate 30SCCM, oxygen flow rate 20SCCM, vacuum pressure in the furnace 0.1Pa, Activation time 5min).

[0031] 2) Open the arc target in the PVD furnace, and perform chromium plating on the surface of the PC / ABS blank (conditions: target power supply current 60A, bias voltage 100V, argon flow rate 50SCCM, vacuum pressure in the furnace 0.1Pa, chrome plating time 12min).

[0032] 3) After chrome plating (metal base film), plasma activation is performed on the surface of the blank (conditions are ion source current 0.3A, bias voltage 100V, working gas is Ar 2 and O 2 Mixed air flow, activation time 5min).

[0033] 4) The blank is out of the oven and sprayed with a layer of 10μm thick UV paint. Bake the paint layer with an IR lamp (6...

Embodiment 2

[0043] Embodiment 2 Production example of a kind of ABS nickel-plated mirror frame

[0044] 1) Send the ABS injection molded blank into the PVD for plasma gas cleaning (conditions: ion source current 1A, bias voltage 100V, 50SCCM Ar 2 , vacuum pressure 0.1Pa, activation time 3min).

[0045] 2) Open the intermediate frequency nickel target in the PVD furnace, and perform nickel plating on the surface of the plastic blank (conditions: target power supply current 10A, bias voltage 90V, 30SCCMAr and 20SCCM oxygen vacuum pressure 0.1Pa, nickel plating time 10min).

[0046] 3) Plasma activation is performed on the surface of the plastic blank after nickel plating (metal base film) (conditions: ion source current 1A, bias voltage 90V, working airflow is Ar 2 and N 2 Mixed air flow, mixing ratio 50 SCCM: 50SCCM, vacuum pressure 0.2Pa, activation time 5min).

[0047] 4) The blank is out of the oven and sprayed with a layer of 25 μm thick UV paint. Bake the paint layer with IR lamp ...

Embodiment 3

[0057] Example 3 An example of a BMC thermosetting plastic blank coated with stainless steel refrigerator handle

[0058] 1) Put the BMC injection molding blank into the PVD furnace for plasma source glow cleaning and activation (conditions: ion source current 1A, bias voltage 100V, nitrogen 50SCCM and argon 50SCCM, vacuum pressure 0.2Pa, activation time 5min).

[0059] 2) The arc target is opened in the PVD furnace, and chromium plating is performed on the surface of the BMC blank (conditions: target source current 50A, bias voltage 100V, 50SCCM of Ar 2 , vacuum pressure 0.1Pa, chrome plating time 10min).

[0060] 3) Plasma activation is performed on the surface of the plastic blank after chrome plating (metal base film) (conditions: ion source current 2A, bias voltage 100V, working air flow is Ar 2 and O 2 Mixed air flow, mixing ratio 50 SCCM: 50SCCM, vacuum pressure 0.2Pa, activation time 5min).

[0061] 4) The blank is out of the furnace and sprayed with a layer of 60 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com