Iron-based alloy powder for laser cladding and preparation method thereof

An iron-based alloy, laser cladding technology, applied in metal processing equipment, metal material coating technology, coating and other directions, can solve the problems of satellite ball, uneven powder particle size distribution, poor crack resistance of the cladding layer, etc. Achieve the effect of low oxygen content, high sphericity and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A preparation method of iron-based alloy powder for laser cladding is as follows:

[0074] (1) Various raw materials required for powder making, such as micro-carbon ferrochrome, ferromolybdenum, silicon block, ferroboron, ferromanganese, ferrovanadium, nickel-chromium pre-alloyed powder, industrial pure iron, according to the iron-based alloy powder Element ratio for weighing;

[0075] (2) after smelting;

[0076] (3) Steel pouring; pour the molten steel with a superheat of ΔT≈300K into the preheated tundish; the temperature of the molten steel is 1550-1580°C, and the entire steel pouring process is controlled within 15 minutes;

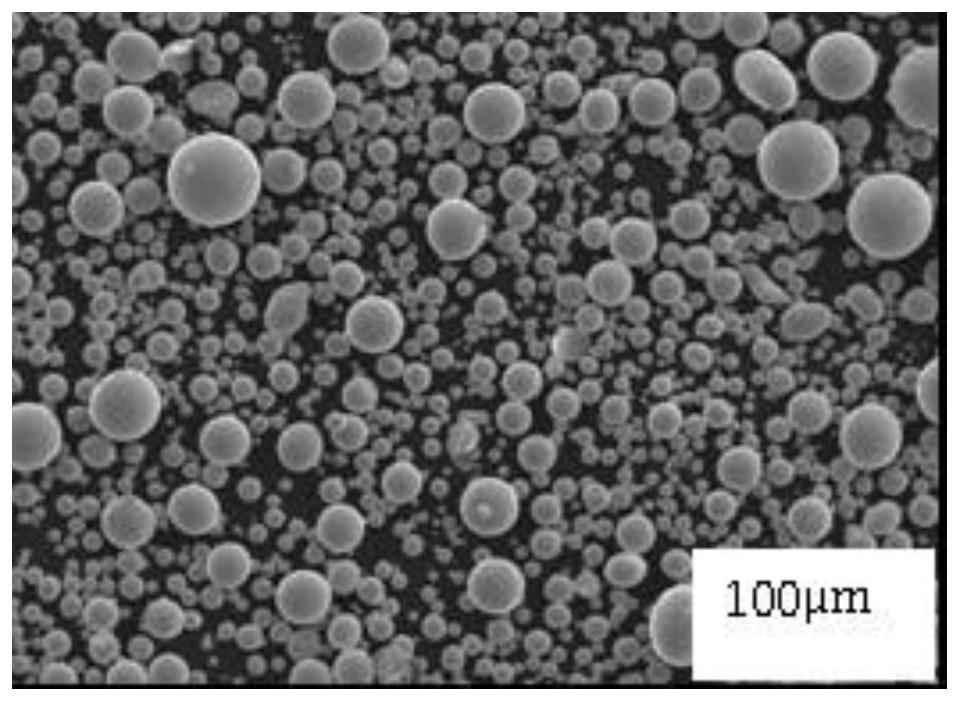

[0077] (4) Inert gas protection atomization; the molten steel flows out from the leak nozzle of the tundish, and simultaneously adopts high-pressure inert gas to protect the outflowing molten steel from being oxidized, and sprays high-pressure inert gas to the outflowing molten steel flow, so that the The outflowing molten steel is atomized...

Embodiment 2-3 and comparative example 1-3

[0082]Examples 2-3 and Comparative Examples 1-3 are basically the same as Example 1, and all raw materials are weighed according to the element ratio of the iron-based alloy powder, after smelting, steel pouring, inert gas protection atomization, airflow classification and sieving , the content of each element of the iron-based alloy powder for laser cladding obtained in Example 2-3 and Comparative Example 1-3 is shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com