Boric low alloy wear resistant steel for pump

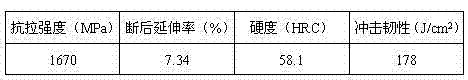

A low-alloy, wear-resistant steel technology, applied in the field of metal casting materials, can solve the problems of reducing the metallurgical quality of wear-resistant steel, damaging the plasticity and toughness of steel, and increasing inclusions, achieving good toughness effect, high wear resistance, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

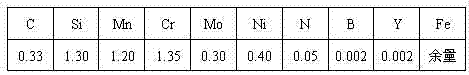

Embodiment 1

[0044] The boron-containing multi-element low-alloy wear-resistant cast steel for pumps in this embodiment is molded with furan resin sand and melted in a 1000kg medium-frequency induction furnace with neutral lining. The required raw materials are: medium-carbon ferrochrome, nitrogen-containing ferrochrome, electrolytic nickel, ferromolybdenum, medium-carbon ferromanganese, ferroboron, ferrosilicon, electrolytic aluminum, scrap steel, foundry pig iron, heavy rare earth yttrium alloy modifier, slagging agent wait. The feeding sequence is as follows: Put scrap steel, ferromolybdenum, electrolytic nickel and cast pig iron into the furnace, and then turn on the electricity, supply 60% of the power at the beginning of the electricity, when the current fluctuation is small, gradually increase the power to the maximum, and at any time Stamping; after most of the charge is melted, add medium-carbon ferrochromium to continue melting, and add ferrosilicon and medium-carbon ferromangane...

Embodiment 2

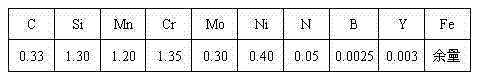

[0050] The boron-containing multi-element low-alloy wear-resistant cast steel for pumps in this embodiment is molded with furan resin sand and smelted in a 1000kg medium-frequency induction furnace with a basic furnace lining. The required raw materials are: medium-carbon ferrochrome, nitrogen-containing ferrochrome, electrolytic nickel, ferromolybdenum, medium-carbon ferromanganese, ferroboron, ferrosilicon, electrolytic aluminum, scrap steel, foundry pig iron, heavy rare earth yttrium alloy modifier, slagging agent etc., the feeding sequence is as follows: put scrap steel, ferromolybdenum, electrolytic nickel and foundry pig iron into the furnace and turn on the electricity, supply 60% power at the beginning of electricity, when the current fluctuation is small, gradually increase the power to the maximum, And pound the material at any time; after most of the charge melts, add medium-carbon ferrochrome to continue melting, and add ferrosilicon and medium-carbon ferromanganese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com