Low-nickel austenitic stainless steel flux-cored welding strip and preparation method thereof

A technology of austenitic stainless steel and stainless steel, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of poor corrosion resistance and wear resistance of the cladding layer, reduce strength and corrosion resistance, and improve grain resistance Inter-corrosion performance and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

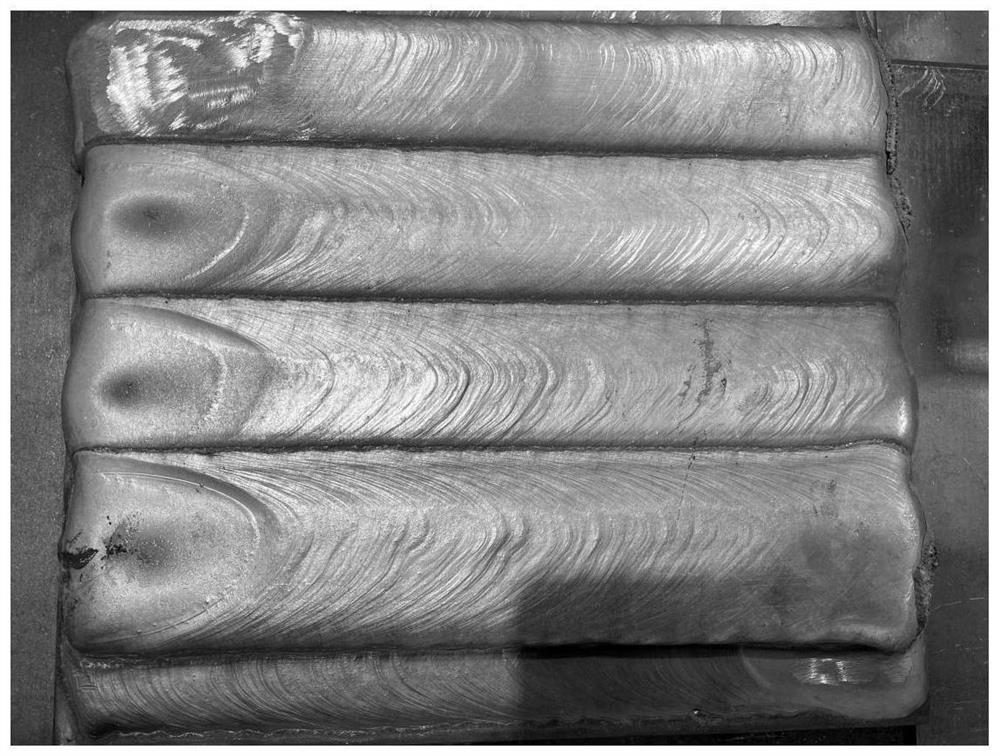

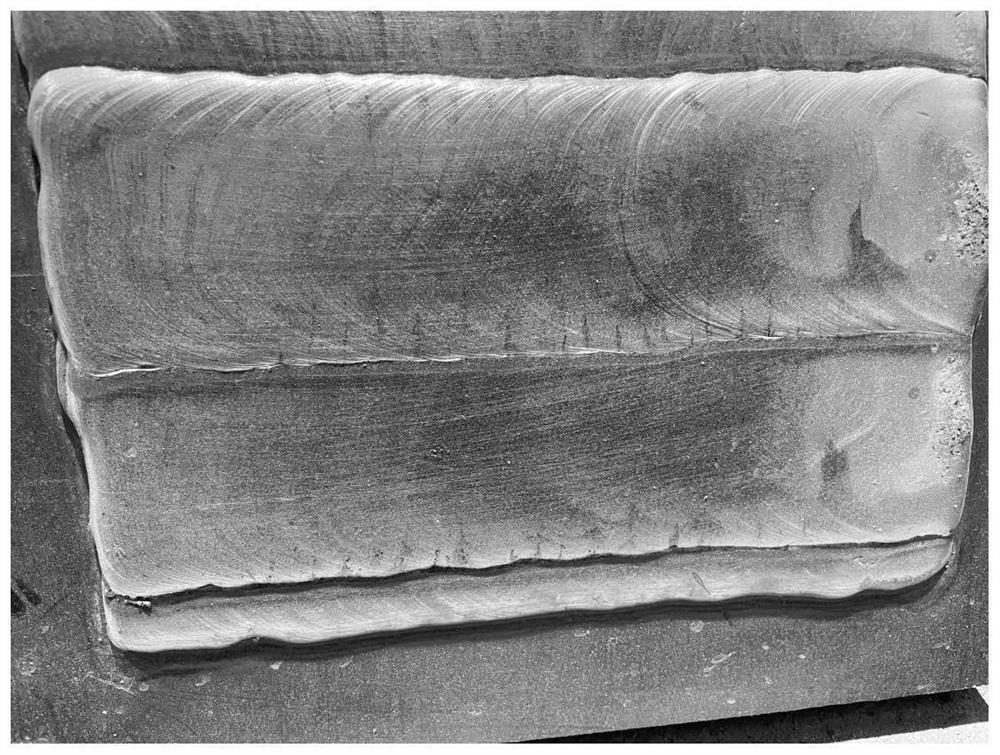

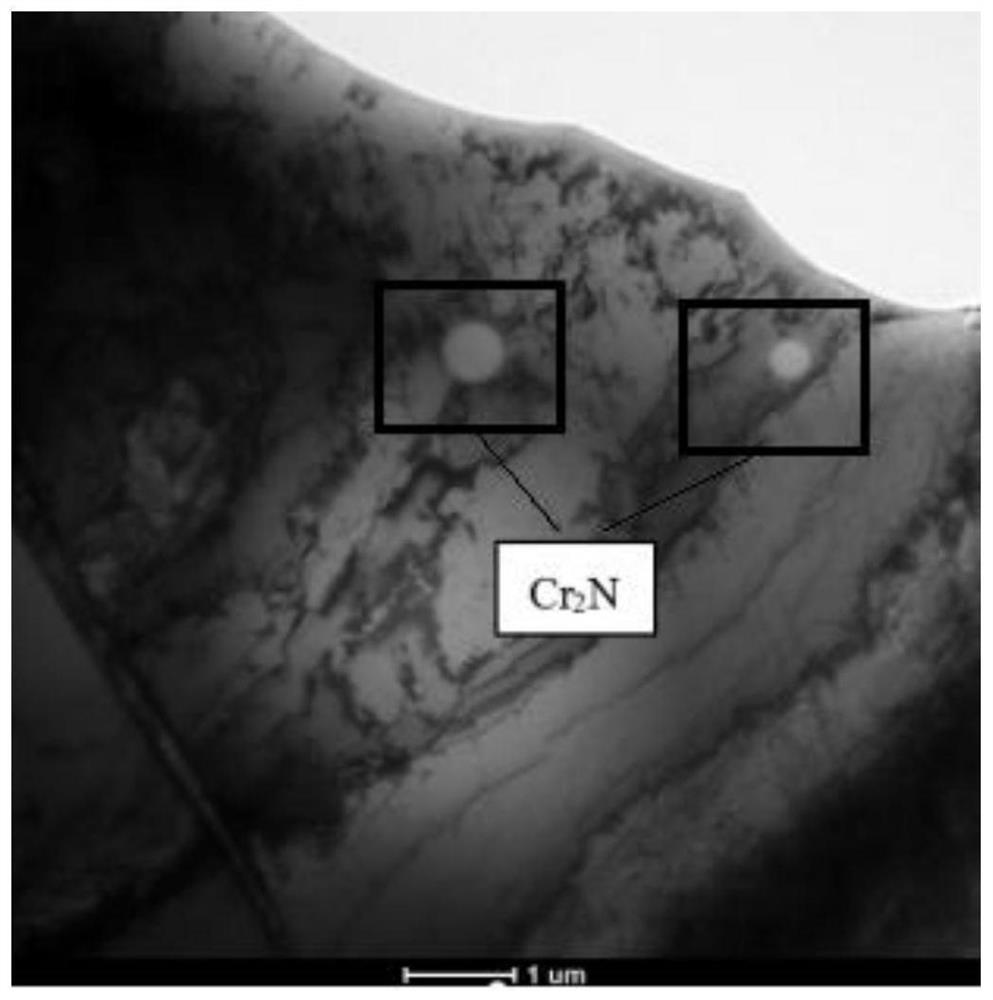

[0030]Embodiment 1: A low-nickel austenitic stainless steel flux-cored welding strip of this embodiment is composed of a 06Cr18Mn5Ni4Cu2N stainless steel sheath and a flux-cored powder filled therein; the flux-cored powder is composed of potassium feldspar: 5%, Rutile: 17%, Zircon Sand: 1%, Al-Mg alloy: 0.5%, Electrolytic Manganese: 22%, Ferrosilicon: 0.5%, Chromium powder: 10%, Nickel powder: 8%, Ferromolybdenum: 0.5%, Copper powder: 5%, metal cobalt powder: 1%, titanium powder: 0.5% and the balance of ferrochromium nitride powder, the nitrogen content of the ferrochromium nitride powder: 8%, the core The particle size of potassium feldspar, rutile and zircon sand in the powder is 80 mesh to 200 mesh, and the particle size of the remaining components is below 80 mesh. The element composition and the mass content of each element in the 06Cr18Mn5Ni4Cu2N stainless steel outer skin are: C: 0.06% , Si: 0.35%, Mn: 5.15%, Ni: 3.50%, Mo: 0.20%, Cu: 1.90%, N: 0.30%, S≤0.001%, P≤0.020%...

Embodiment 2

[0039] Embodiment 2: A low-nickel austenitic stainless steel flux-cored welding strip of this embodiment is composed of a 06Cr18Mn5Ni4Cu2N stainless steel sheath and a flux-cored powder filled therein; the flux-cored powder is composed of potassium feldspar: 6%, Rutile: 20%, Zircon Sand: 1.5%, Al-Mg alloy: 0.85%, Electrolytic Manganese: 24%, Ferrosilicon: 0.8%, Chromium powder: 12%, Nickel powder: 9%, Ferromolybdenum: 1%, Copper powder: 8%, metal cobalt powder: 1.5%, titanium powder: 0.8% and the balance of ferrochromium nitride powder. The nitrogen content of the ferrochromium nitride powder is: 10%. The particle size of potassium feldspar, rutile and zircon sand in the powder is 80 mesh to 200 mesh, and the particle size of the remaining components is below 80 mesh. The element composition and mass content of each element in the 06Cr18Mn5Ni4Cu2N stainless steel outer skin are: C: 0.07% , Si: 0.40%, Mn: 5.45%, Ni: 3.82%, Mo: 0.12%, Cu: 1.96%, N: 0.37%, S≤0.001%, P≤0.020%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com