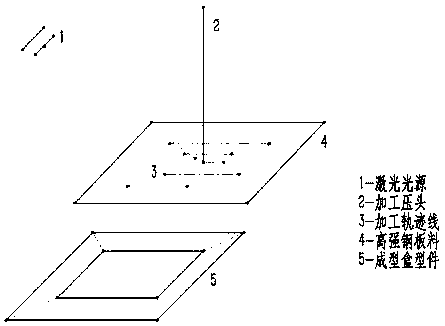

High-strength steel laser-assisted incremental forming technology

An incremental forming, laser-assisted technology, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems that processing tools and equipment are difficult to meet processing requirements, processing tools are worn, and accidents are prone to occur, and reduce processing. Heat-affected zone, reduced equipment loss, uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Taking the processing of box-shaped parts as an example to illustrate, the specific steps are as follows:

[0020] (1) Design the processing trajectory. According to the shape and size of the required parts, design the trajectory of the processing indenter and laser heating, so that the indenter and laser can process and heat the high-strength steel sheet along the trajectory.

[0021] (2) Turn on the laser to heat the geometric center of the sheet, heat for a certain period of time to soften the high-strength steel sheet to a certain extent to facilitate plastic deformation, and then move at a constant speed along the trajectory to uniformly heat the sheet.

[0022] (3) At the same time, the processing head pressurizes the sheet to cause plastic deformation, and moves at a constant speed along the processing track. The processing speed is consistent with the heating speed, thereby ensuring low deformation resistance.

[0023] (4) After processing, turn off the laser, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com