Semi-automatic gas shield welding construction technology for aluminum conductors

A construction process and technology of aluminum conductors, which are applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of complicated preparation process, low labor efficiency, burners caused by strong acid and alkali, and reduce slag inclusion and unwelded welding. The probability of penetration defects, the guarantee of welding quality, and the effect of improving the quality of welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

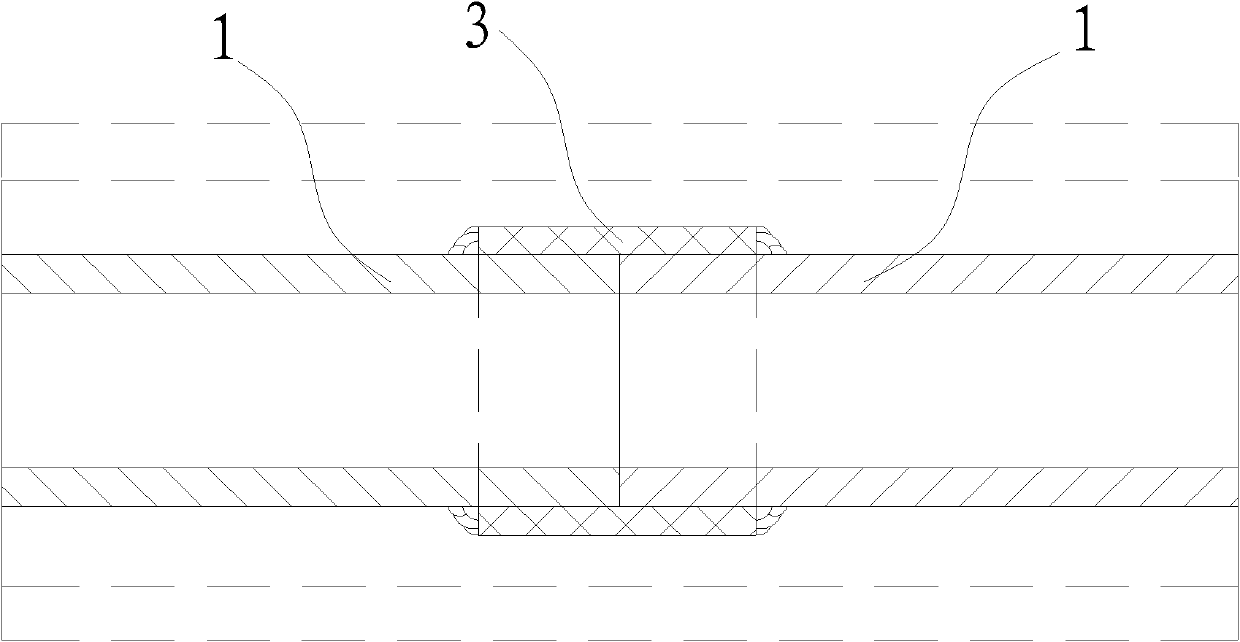

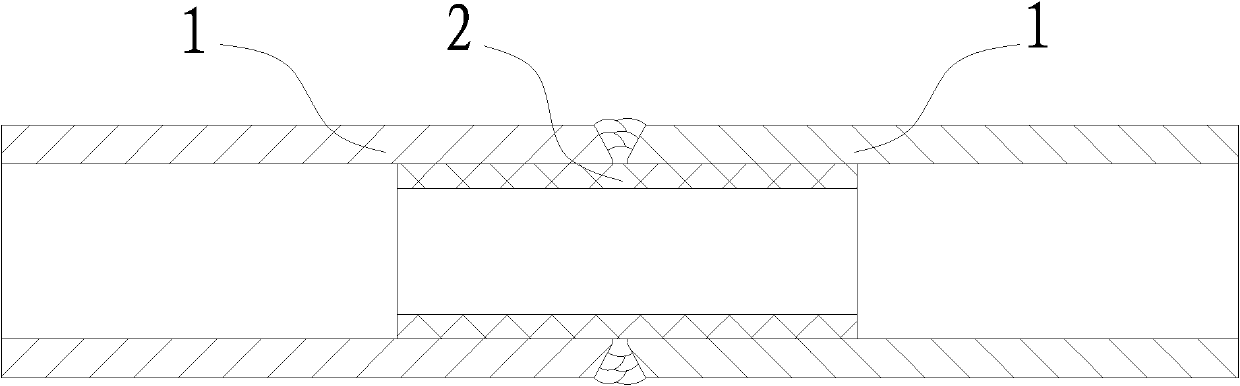

[0019] like figure 1 , figure 2 Shown is a semi-self gas shielded welding construction process for tubular aluminum conductors provided by the present invention with safe operation, high production efficiency and guaranteed welding quality. The construction process includes the following steps:

[0020] a. Assembly of aluminum conductors: Assemble the tubular aluminum conductors 1 that need to be welded and connected as required;

[0021] b. Preparation of welding equipment. While assembling the aluminum conductor, first install the U-shaped wire feeder, soft plastic wire guide sleeve and air-cooled welding torch on the four-wheel wire feeder of the semi-automatic gas shielded welding equipment, and then install the four-wheel wire feeder. The sending machine is installed on the positive pole of the semi-automatic DC gas shielded welding equipment to form a DC reverse connection state, and the arc force soft and hard selection button of the semi-automatic DC gas shielded we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com