Preparation method of PTFE/SiO2/Al2O3 porous membrane coated on surface of porous aluminum

A technology of surface coating and PTFE, which is used in devices for coating liquids on surfaces, special surfaces, pre-treated surfaces, etc., can solve the problems of reducing the friction between sound waves and porous aluminum, reducing sound absorption performance, etc. The effect of sound function application, high preparation efficiency and high sound absorption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

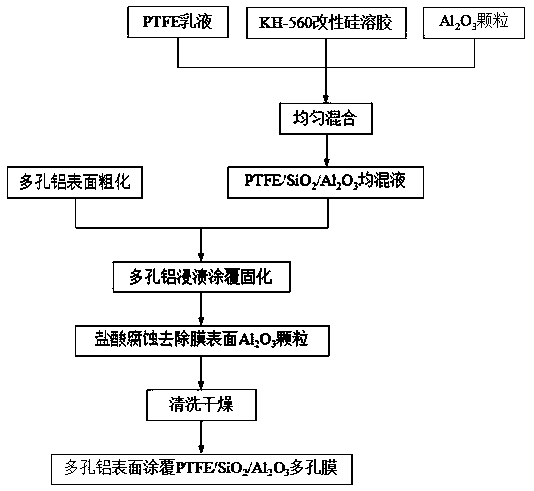

[0034] A porous aluminum surface coated with PTFE / SiO 2 / Al 2 o 3 The preparation method of porous film, concrete steps are as follows:

[0035] (1) PTFE / SiO2 2 / Al 2 o 3 Preparation of homogenate

[0036] PTFE emulsion, KH-560 modified silica sol and Al with a particle size of 1-3 μm 2 o 3 Particle mixing, wherein the volume ratio of PTFE emulsion and KH-560 modified silica sol is 1:0.5, Al 2 o 3 The volume fraction of particles is 40% of the total volume of PTFE emulsion and KH-560 modified silica sol, and the PTFE emulsion, KH-560 modified silica sol and Al 2 o 3 The mixture of particles was magnetically stirred for 5h to obtain PTFE / SiO 2 / Al 2 o 3 homogenate.

[0037] (2) Surface roughening of porous aluminum

[0038] Put the porous aluminum with a porosity of 60%, a pore diameter of 0.1mm, and a through-pore structure into a 0.8mol / L NaOH solution for 60s and corrode the corroded porous aluminum with deionized water, shake and wash, and obtain a roughened ...

Embodiment 2

[0046] A porous aluminum surface coated with PTFE / SiO 2 / Al 2 o 3 The preparation method of porous film, concrete steps are as follows:

[0047] (1) PTFE / SiO2 2 / Al 2 o 3 Preparation of homogenate

[0048] PTFE emulsion, KH-560 modified silica sol and Al with a particle size of 3-5 μm 2 o 3 Particle mixing, wherein the volume ratio of PTFE emulsion and KH-560 modified silica sol is 1:0.55, Al 2 o 3 The volume fraction of particles is 31% of the total volume of PTFE emulsion and KH-560 modified silica sol, and the PTFE emulsion, KH-560 modified silica sol and Al 2 o 3 The mixture of particles was magnetically stirred for 4.5h to obtain PTFE / SiO 2 / Al 2 o 3 homogenate.

[0049] (2) Surface roughening of porous aluminum

[0050] The porous aluminum with a porosity of 70%, a pore diameter of 1mm, and a through-pore structure was put into a 0.9mol / L NaOH solution and corroded for 90s. The corroded porous aluminum was shaken and washed with deionized water, and the po...

Embodiment 3

[0058] A porous aluminum surface coated with PTFE / SiO 2 / Al 2 o 3The preparation method of porous film, concrete steps are as follows:

[0059] (1) PTFE / SiO2 2 / Al 2 o 3 Preparation of homogenate

[0060] PTFE emulsion, KH-560 modified silica sol and Al with a particle size of 5-8 μm 2 o 3 Particle mixing, wherein the volume ratio of PTFE emulsion and KH-560 modified silica sol is 1:0.6, Al 2 o 3 The volume fraction of particles is 23% of the total volume of PTFE emulsion and KH-560 modified silica sol, and the PTFE emulsion, KH-560 modified silica sol and Al 2 o 3 The mixture of particles was magnetically stirred for 4 hours to obtain PTFE / SiO 2 / Al 2 o 3 homogenate.

[0061] (2) Surface roughening of porous aluminum

[0062] The porous aluminum with a porosity of 80%, a pore diameter of 2mm, and a through-pore structure was put into a 1mol / L NaOH solution and corroded for 120s. The corroded porous aluminum was shaken and washed with deionized water, and the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com