Patents

Literature

33results about How to "Improve poor adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

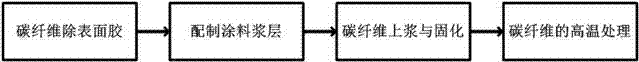

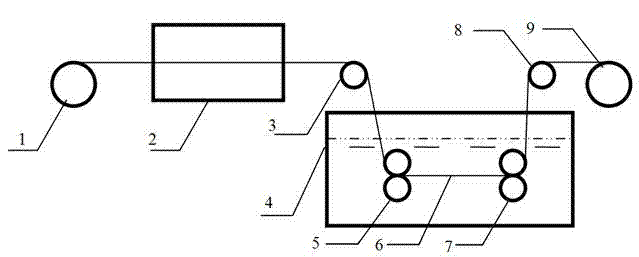

Preparation method of carbon fiber surface antioxidation coating

InactiveCN103924443AEasy to achieve continuous coatingImprove poor adhesionCarbon fibresFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber surface antioxidation coating, which belongs to the technical field of inorganic non-metallic material. The preparation method comprises the following steps: using an organic solvent to remove a glue layer and an attachment on the surface of the carbon fiber, taking a silane coupling agent as a precursor to prepare a coating slurry; coating the obtained coating slurry on the surface of the carbon fiber product and drying; in 99.999% of inert atmosphere, and processing the dried carbon fiber product under high temperature of 800-1600 DEG C for 30-360 minutes to obtain the carbon fiber surface antioxidation coating. According to the invention, the silane coupling agent is taken as a precursor, and is easily infiltrated with carbon fiber to form an uniform coating, the enhanced particles can improve the defects of poor clunging of the coating and cracking of the coating; the solidification time is short, the solidification temperature is low, and automation mechanical equipment is cooperated for easily realizing the continuous coating of the coating.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

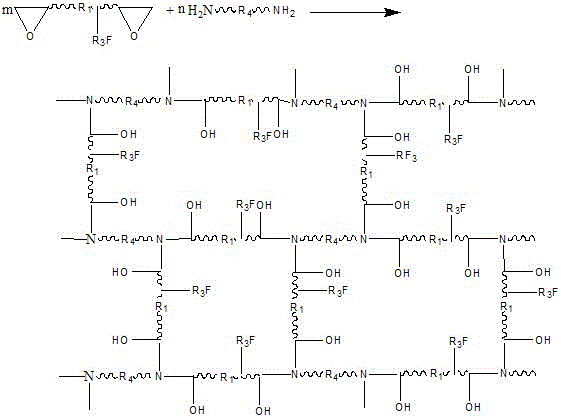

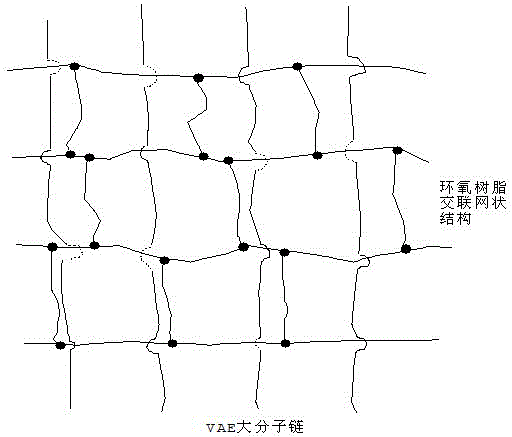

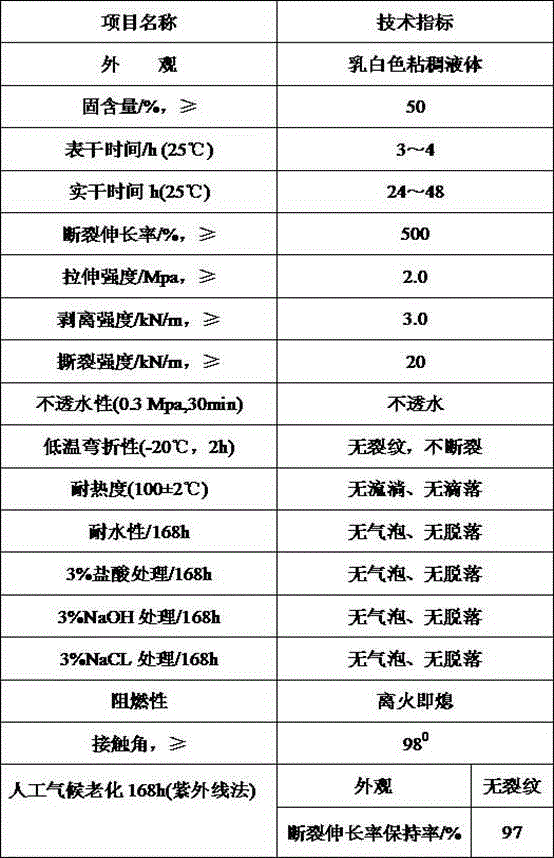

Epoxy resin modified VAE composite waterproof material and preparation method thereof

ActiveCN103555091AImprove water resistanceIncrease crosslink densityFireproof paintsAntifouling/underwater paintsPropanoic acidPhosphoric acid

An epoxy resin modified VAE composite waterproof material and a preparation method thereof. The composite waterproof material is composed of a component A and a component B. A preparation method of the component A is as below: adding a vinyl acetate-ethylene copolymer emulsion into a material canister, then adding an epoxy resin emulsion and a defoaming agent, stirring, then adding aluminum hydroxide, phosphoric acid tris(2-chloroethyl) ester, talcum powder, a polytetrafluoroethylene fine powder, tetra [beta-(3,5-di-t-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester, 2-(2H-benzo triazoles-2-yl)-6-dodecyl-4-methylphenol and water, and stirring to obtain the component A. A preparation method of the component B is as below: under the protection of nitrogen, adding tetraethylenepentamine into a reactor, dropwise adding ethylene glycol diglycidylether and butyl glycidol ether for a thermal reaction, then adding water to dilute and stirring to obtain the B component. The component A and the component B are stirred according to a part ratio of 100: 5-8 and applied; and after curing, a flame retardant antifouling self-cleaning composite waterproof material with a semi-interpenetrating network macro-molecular structure is obtained.

Owner:太原英可奥笔墨科技有限公司

Waterborne antistatic wear-resistant coating

InactiveCN105038371AGood wear resistanceImprove poor adhesionCoatingsDefoaming AgentsCalcium carbonate

The invention provides a waterborne antistatic wear-resistant coating. The waterborne antistatic wear-resistant coating comprises 25-35% of water, 25-30% of waterborne resin, 0.7-2% of film-forming additives, 0.8-2.5% of dispersing agent, 0.3-1% of levelling agent, 0.1-0.2% of defoaming agent, 2-3.5% of waterborne adhesion promoter, 0.3-5% of titanium dioxide, 0-10% of talcum powder, 0-18% of nano calcium carbonate, 1-1.5% of pH regulator, 10-15.5% of silicon carbide and 6.5-10% of antistatic agent. The waterborne antistatic wear-resistant coating has the advantages of strong adhesion, good wear resistance, antistatic property, acid and alkali resistance, economical property and environment friendliness.

Owner:TAICANG JINXIN PAINT

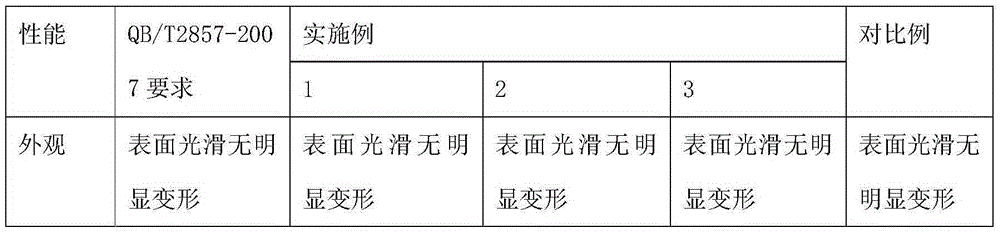

Glue rod material capable of improving low-temperature glueyness and preparation method thereof

ActiveCN105400471AHigh bonding strengthImprove temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTO-18Materials science

The invention discloses a glue rod material capable of improving low-temperature glueyness. The glue rod material comprises the following raw materials by mass: 20 to 30 parts of a gluing base material, 10 to 18 parts of a glueyness modifier, 10 to 15 parts of a shape setting agent, 5 to 10 parts of a humectants, 0.2 to 0.5 part of other aids and 30 to 47 parts of water, wherein the mass parts of all the raw materials sum to 100. The invention also discloses a preparation method for the glue rod material capable of improving low-temperature glueyness at the same time. The glue rod material provided by the invention has the advantages of good intersolubility among the raw materials, excellent glueyness, glueyness in a wide temperature range, and in particular, capability of improving the problem of poor glueyness of conventional solid gum at low temperature.

Owner:苏州冰心文化用品有限公司

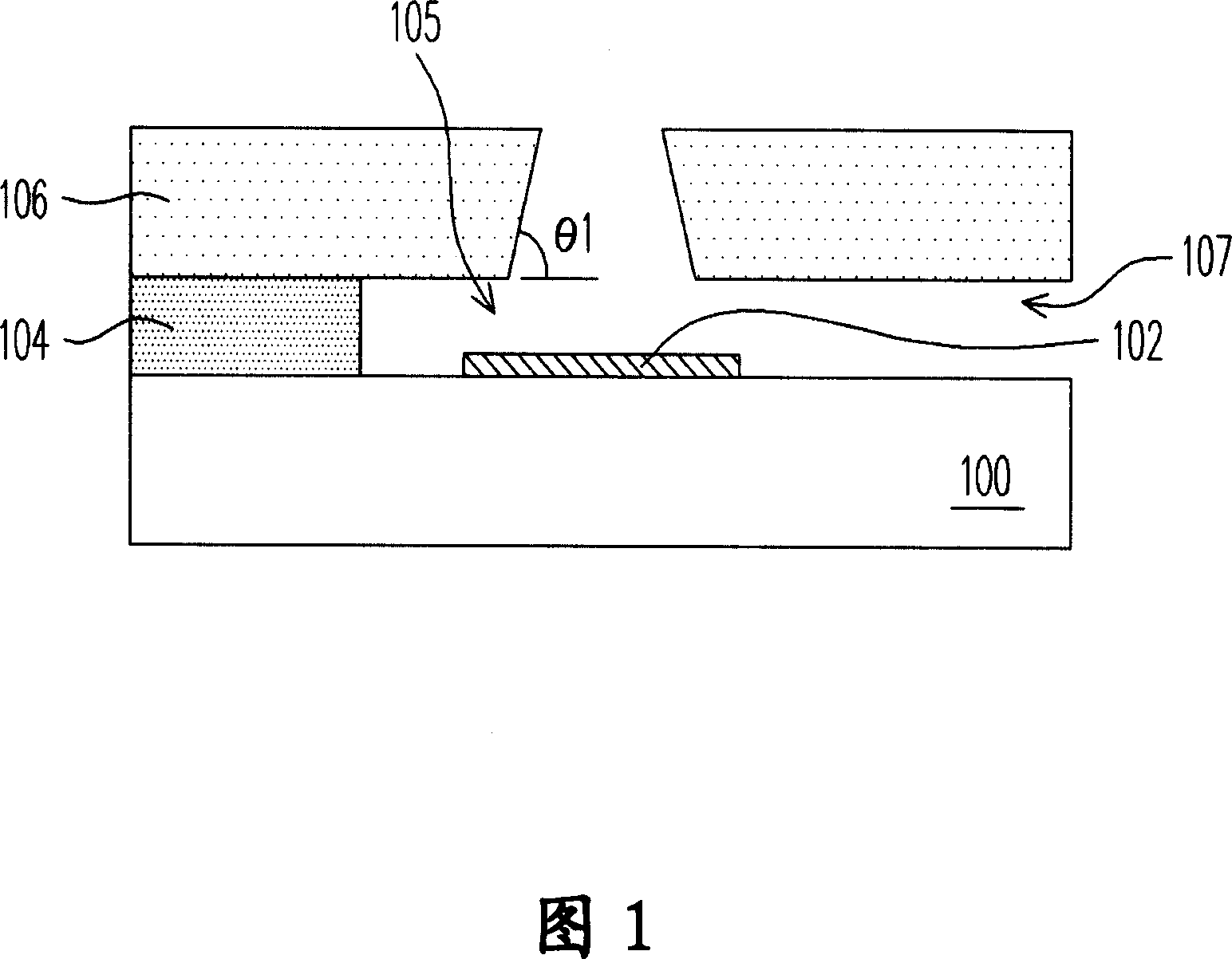

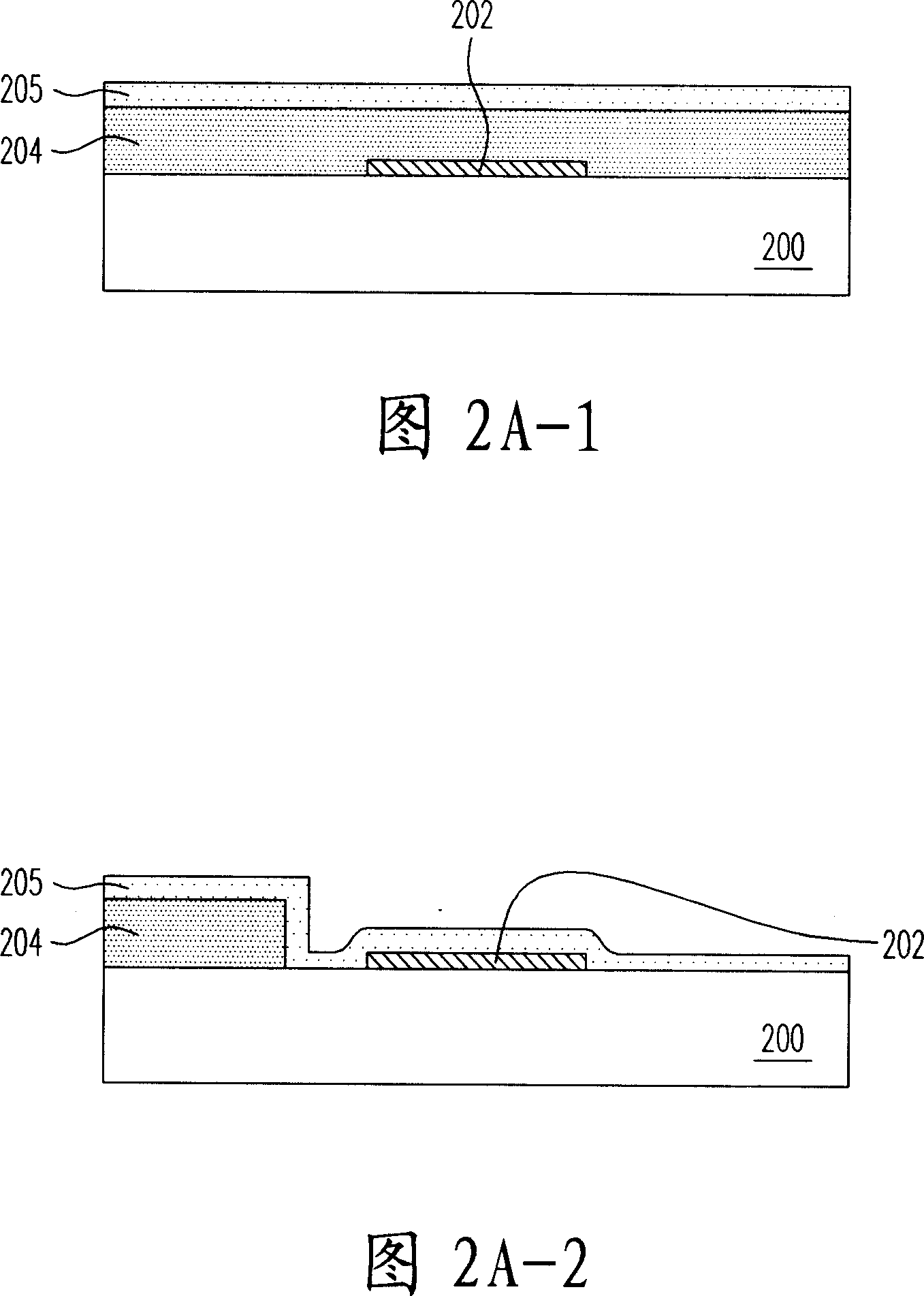

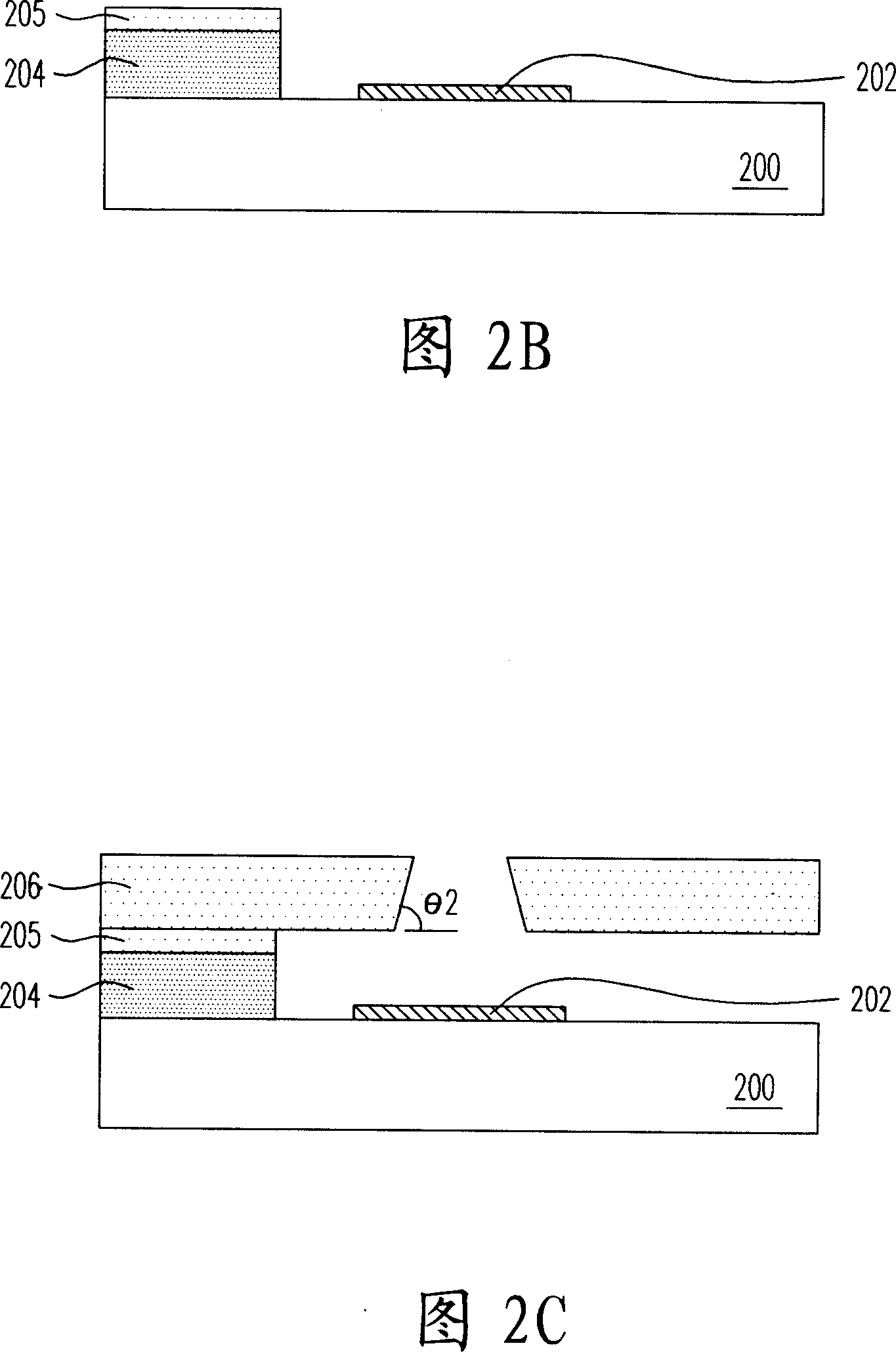

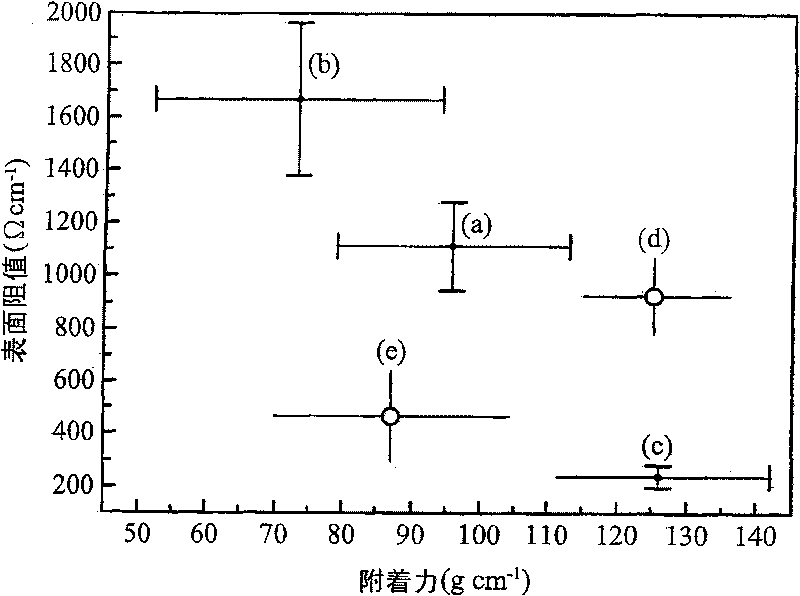

Ink jet printing head and its producing method

The invention provides an ink injection print head which comprises at least a wafer, a chamber layer and a nozzle layer; wherein, the wafer is provided with a plurality of actuators; the chamber layer is arranged on the wafer; the nozzle layer is arranged on the chamber layer which is provided with a plurality of chambers; the chambers are arranged above the actuators; the material of the chamber layer is an organic solvent developed acrylic acid negative-typed photoresist. Furthermore, the nozzle layer is provided with a plurality of nozzles which are respectively communicated with the chambers; the material of the nozzles is the epoxy-typed or acyl imino group-typed negative-typed photoresist.

Owner:INT UNITED TECH

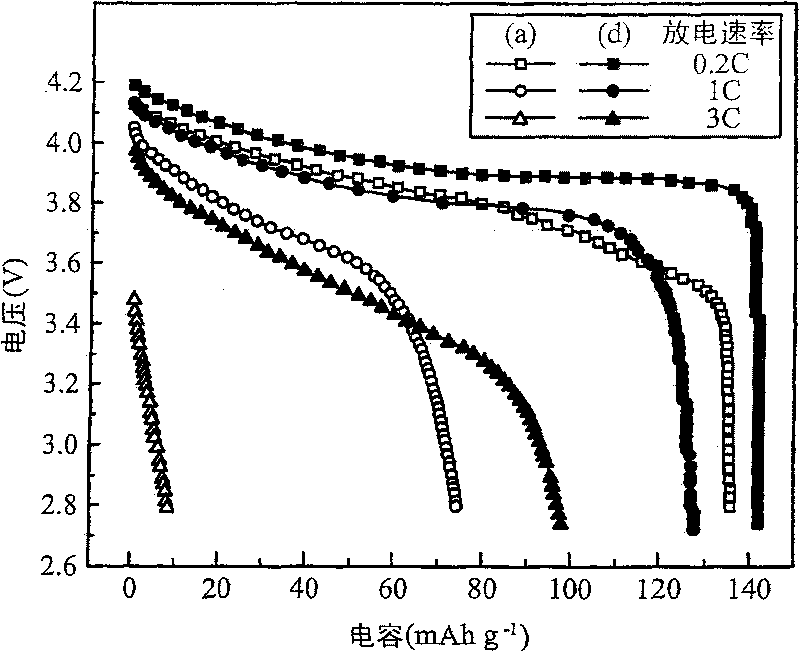

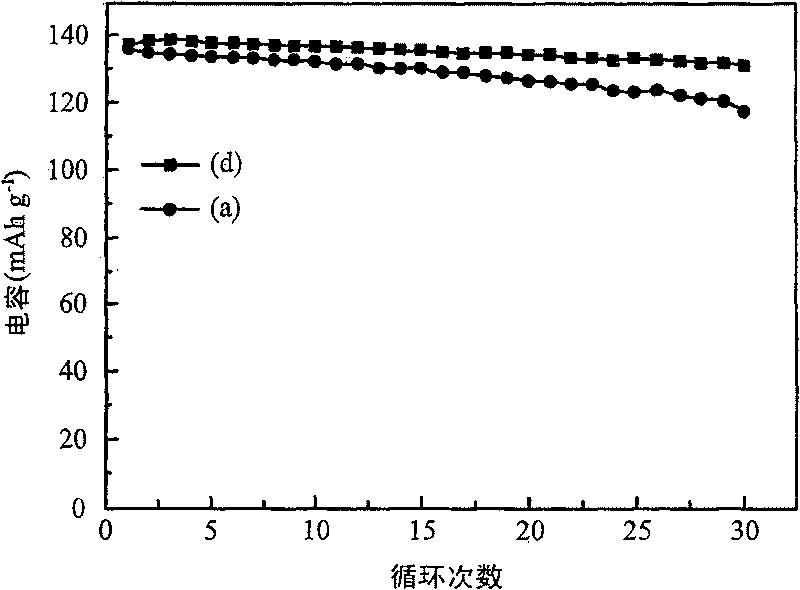

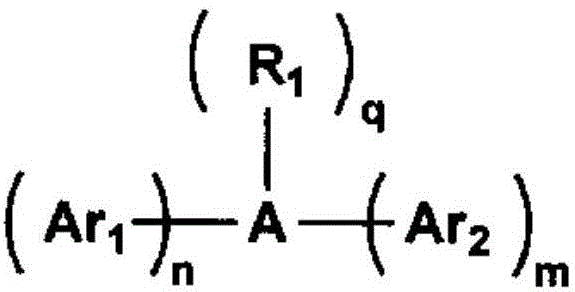

Energy storing assembly

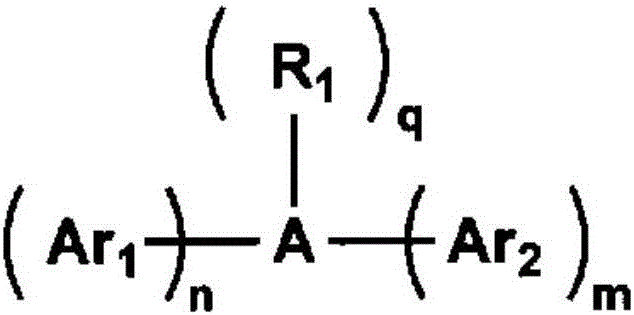

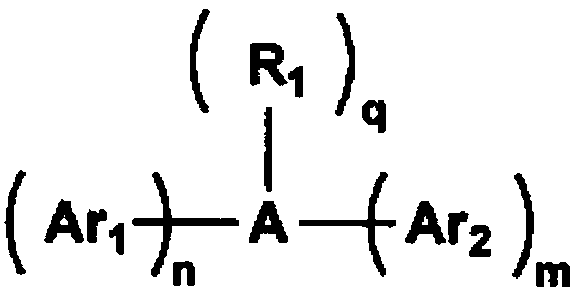

ActiveCN101764266AImprove poor adhesionIncrease polarityElectrode manufacturing processesElectrolytic capacitorsCarbon numberAdhesive

The invention provides an energy storing assembly which comprises a positive electrode, a negative electrode and electrolyte, wherein the positive electrode is mixed with a polyacrylate aqueous adhesive. The polyacrylate aqueous adhesive has the chemical formula, wherein X is alkyl with the carbon number of 1-6, and n is 500-2,500.

Owner:IND TECH RES INST

Ultrathin tempered film and preparation process thereof

InactiveCN110922052AImprove tempered strengthHigh hardnessFlexible article cleaningCoatingsNumerical controlCutting glass

The invention discloses an ultrathin tempered film and a preparation process thereof. The preparation process comprises the following processes: S1, cutting: cutting a glass substrate into required shapes and sizes by adopting a cutting machine; S2, CNC fine carving: carving a hole site corresponding to the type of an electronic product in the cut glass substrate by a numerical control machine tool; S3, primary ultrasonic cleaning: putting the glass substrate into an ultrasonic cleaning machine, and cleaning; S4, tempering and strengthening: tempering and strengthening the glass substrate through a physical method and a chemical method; S5, AF electric / spray plating: carrying out electric / spray plating of anti-fingerprint oil on the surface of the glass substrate; S6, secondary ultrasoniccleaning: putting the glass substrate into an ultrasonic cleaning machine, and carrying out secondary cleaning; and S7, protective film coating: laminating protective films on two surfaces of the glass substrate, packaging and warehousing. The prepared ultrathin tempered film is light and thinner, has good toughness and shock resistance, and can be safely used for a long time.

Owner:东莞市国基光电有限公司

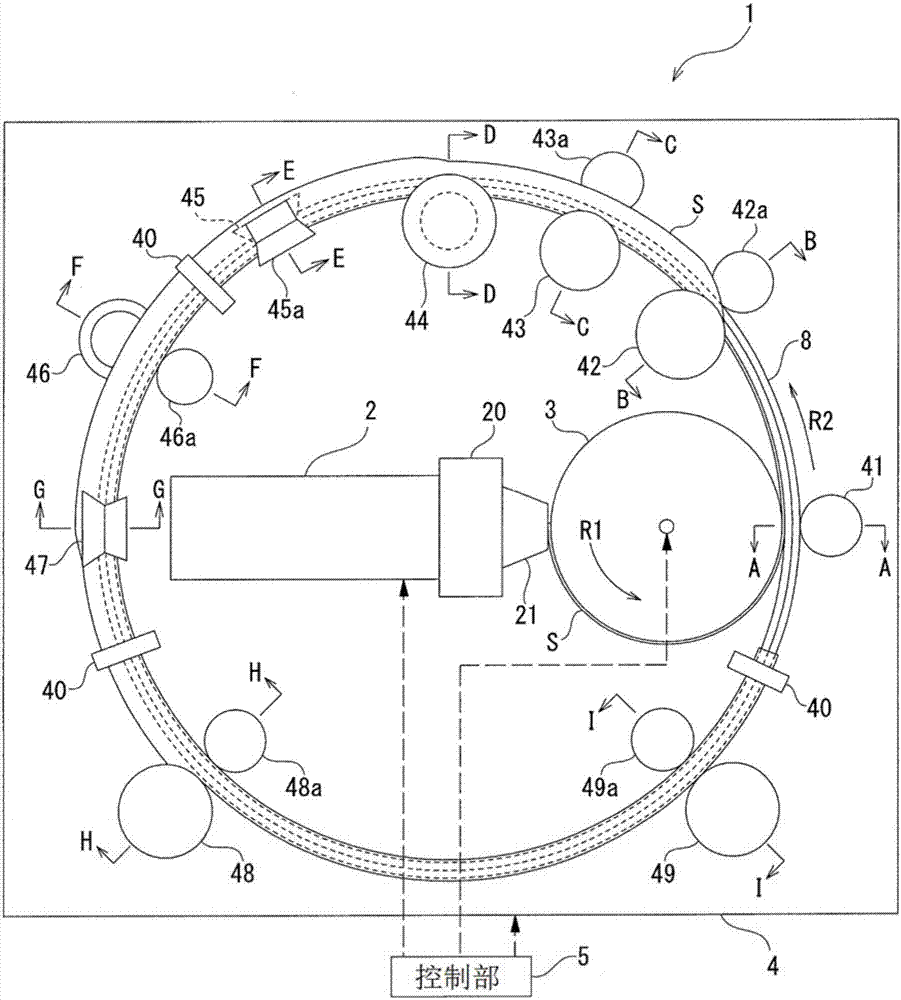

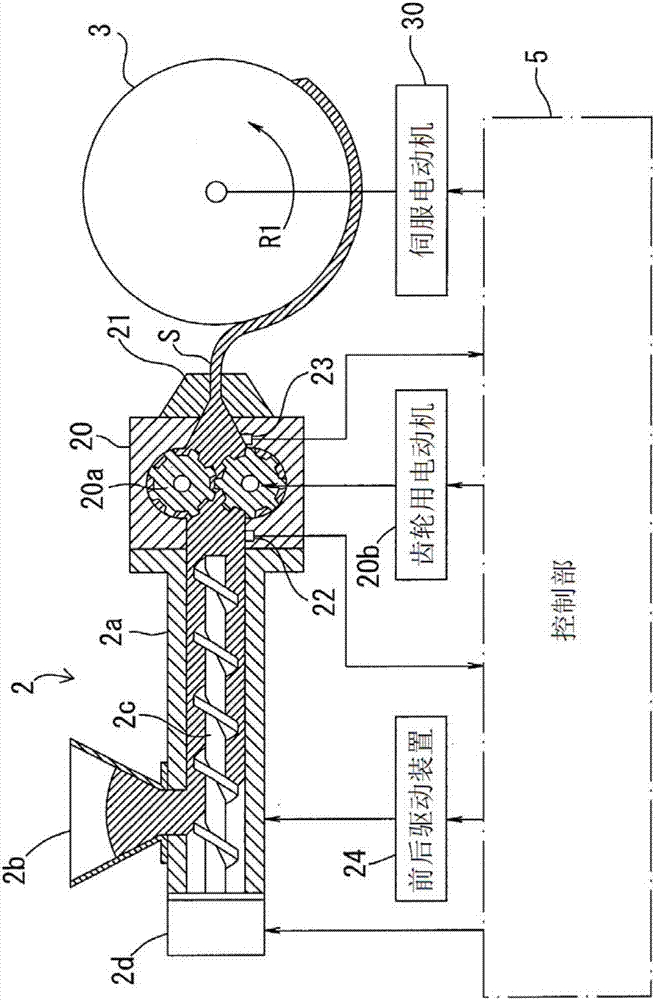

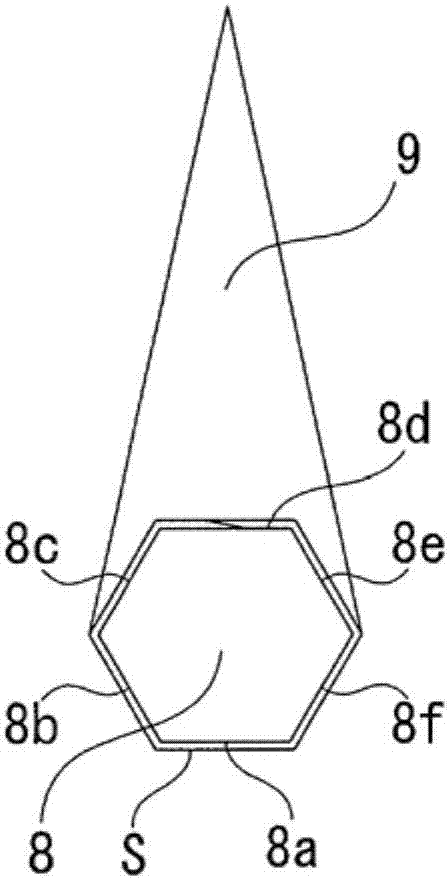

Bead core covering method and bead core covering device

A bead core covering method for covering an annular bead core (8) with a belt-like rubber sheet (S) includes winding the rubber sheet (S) extruded by an extruding machine (2) via a mouth piece (21) around an outer peripheral surface of a rotary drum (3) from a leading end portion, attaching a part in a width direction of the rubber sheet (S) on the outer peripheral surface of the rotary drum (3) to an outer surface of the bead core (8), which rotates, from the leading end portion before the rubber sheet is wound over an entire periphery of the outer peripheral surface of the rotary drum (3), and wrapping a remaining portion in the width direction of the rubber sheet (S) attached to the outer surface of the bead core (8) along a cross-sectional shape of the bead core (8).

Owner:TOYO TIRE & RUBBER CO LTD

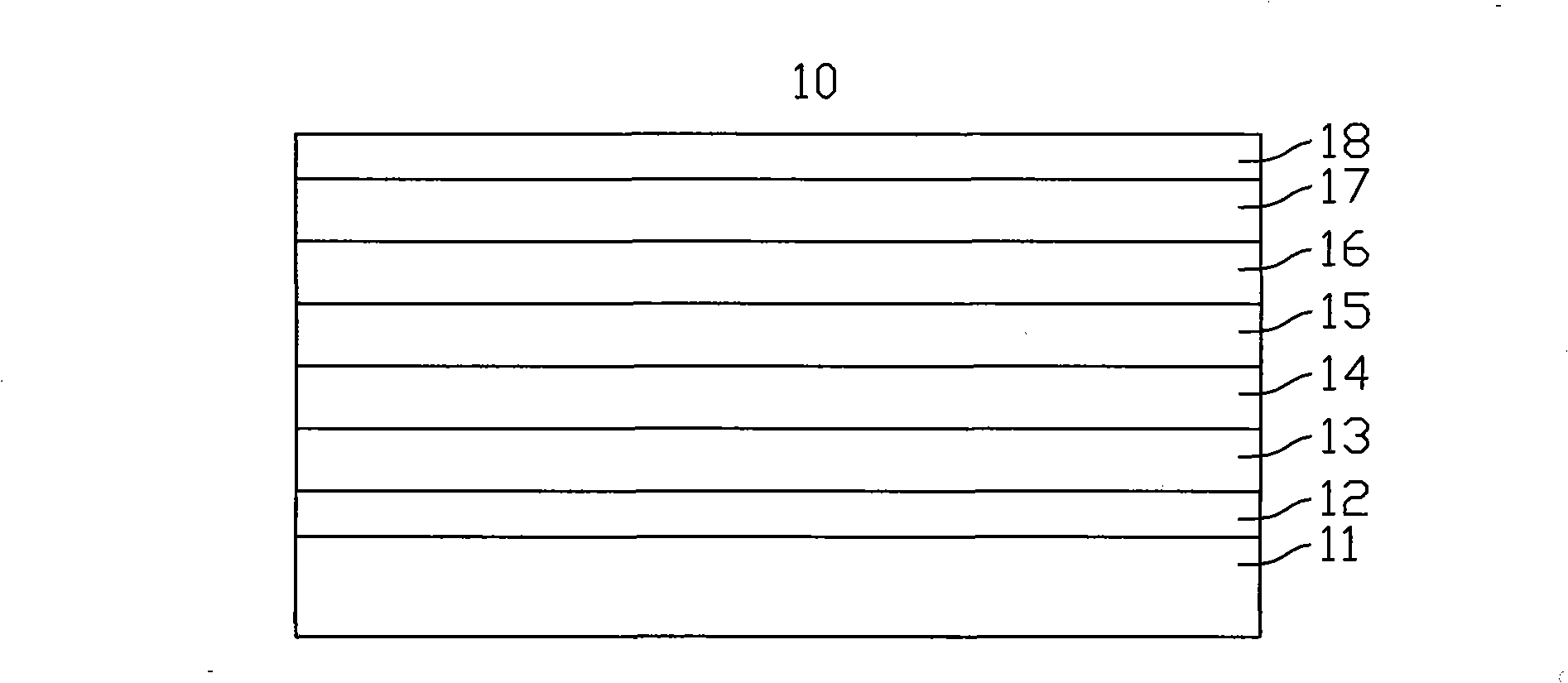

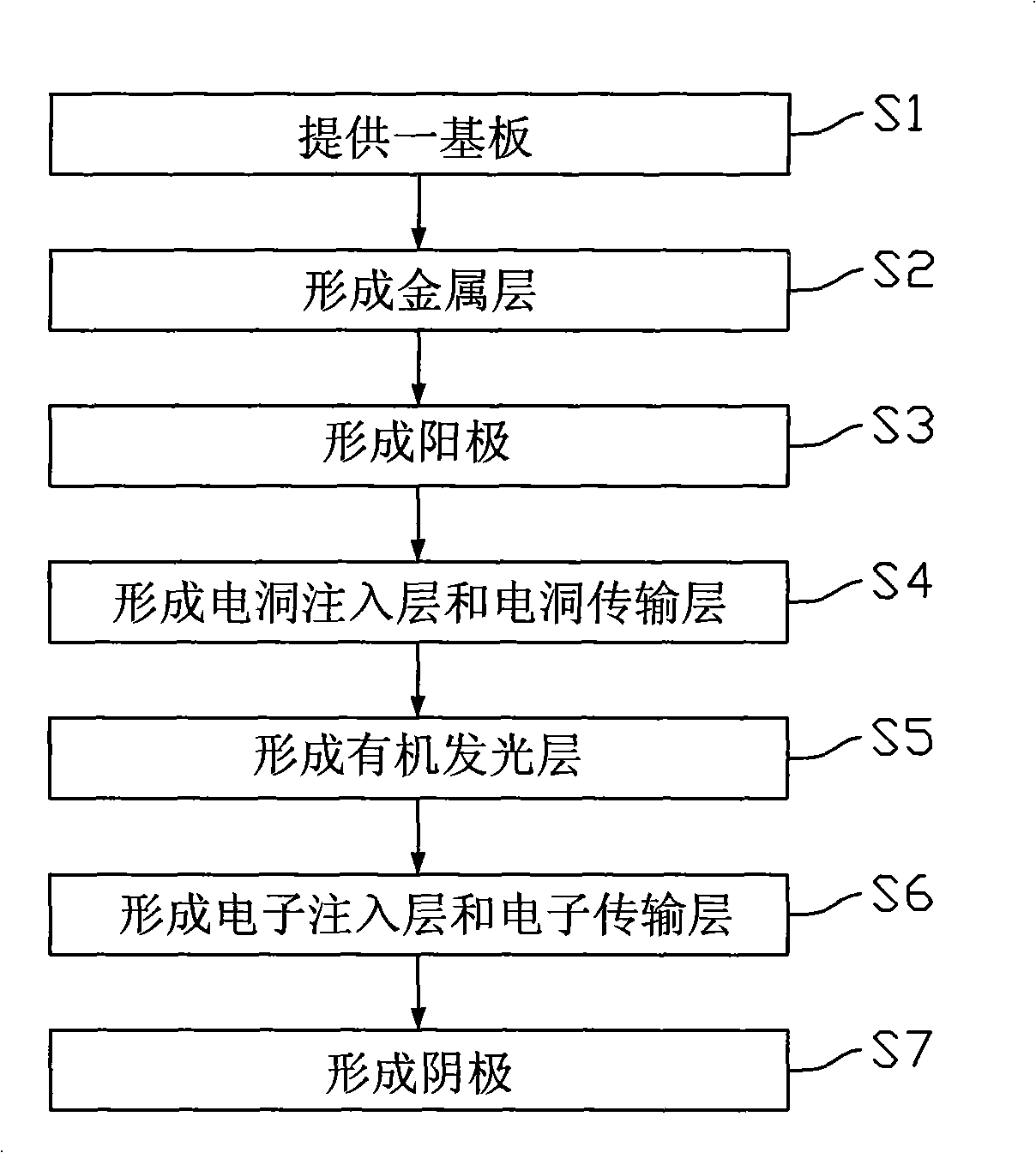

Organic LED and manufacture method thereof

ActiveCN101304075AImprove poor adhesionAvoid separationSolid-state devicesSemiconductor/solid-state device manufacturingAnodeOLED

The invention relates to an organic light emitting diode (LED) and a manufacturing method thereof. The organic LED comprises an insulation substrate, an anode, a hole implanted layer, a hole transfer layer and an organic emitting layer; the anode, the hole implanted layer, the hole transfer layer and the organic emitting layer are arranged on the insulation substrate in sequence; wherein, the anode is provided with fluorinion. The organic LED has better hole implanting effect.

Owner:INNOCOM TECH SHENZHEN +1

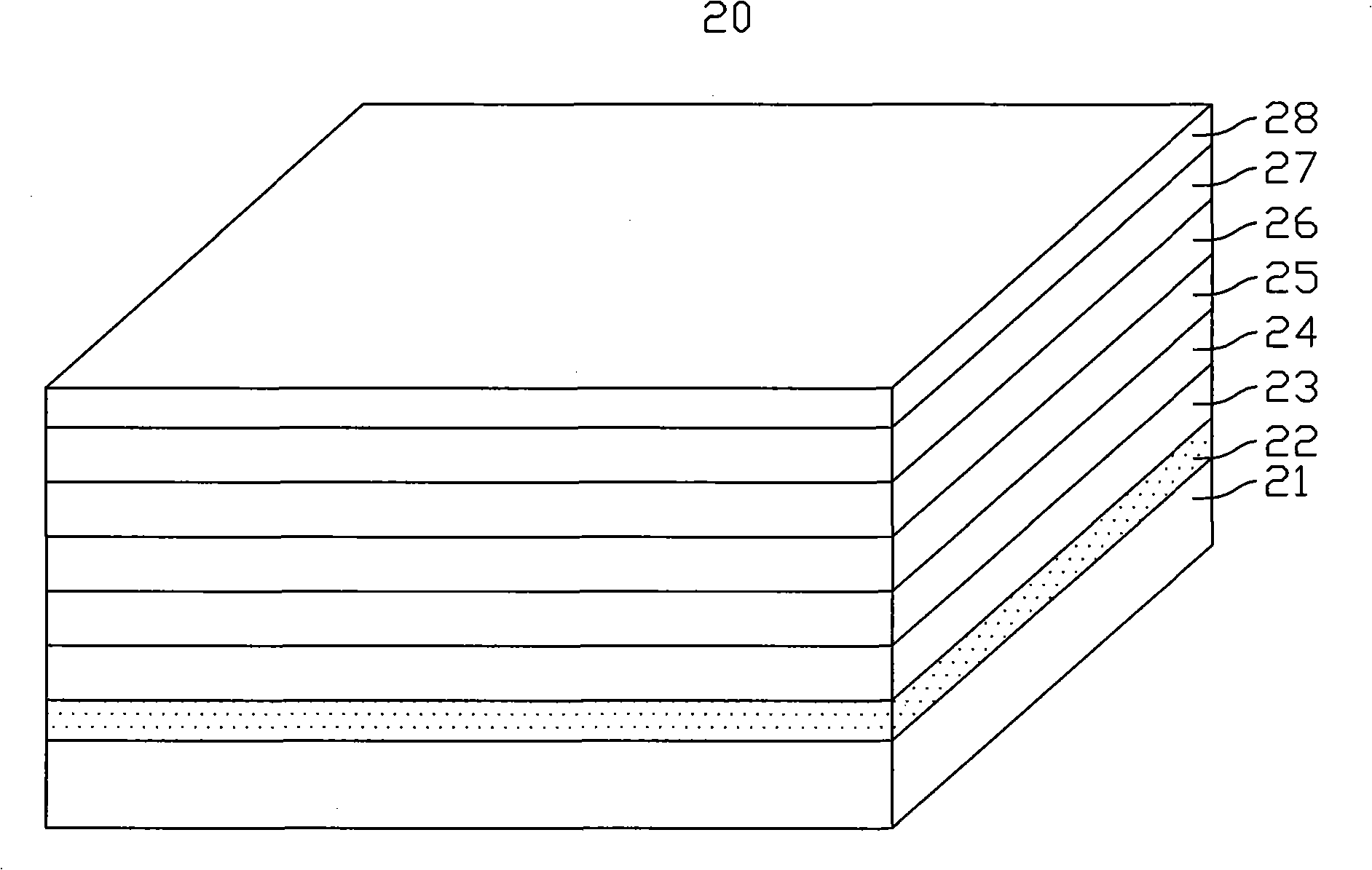

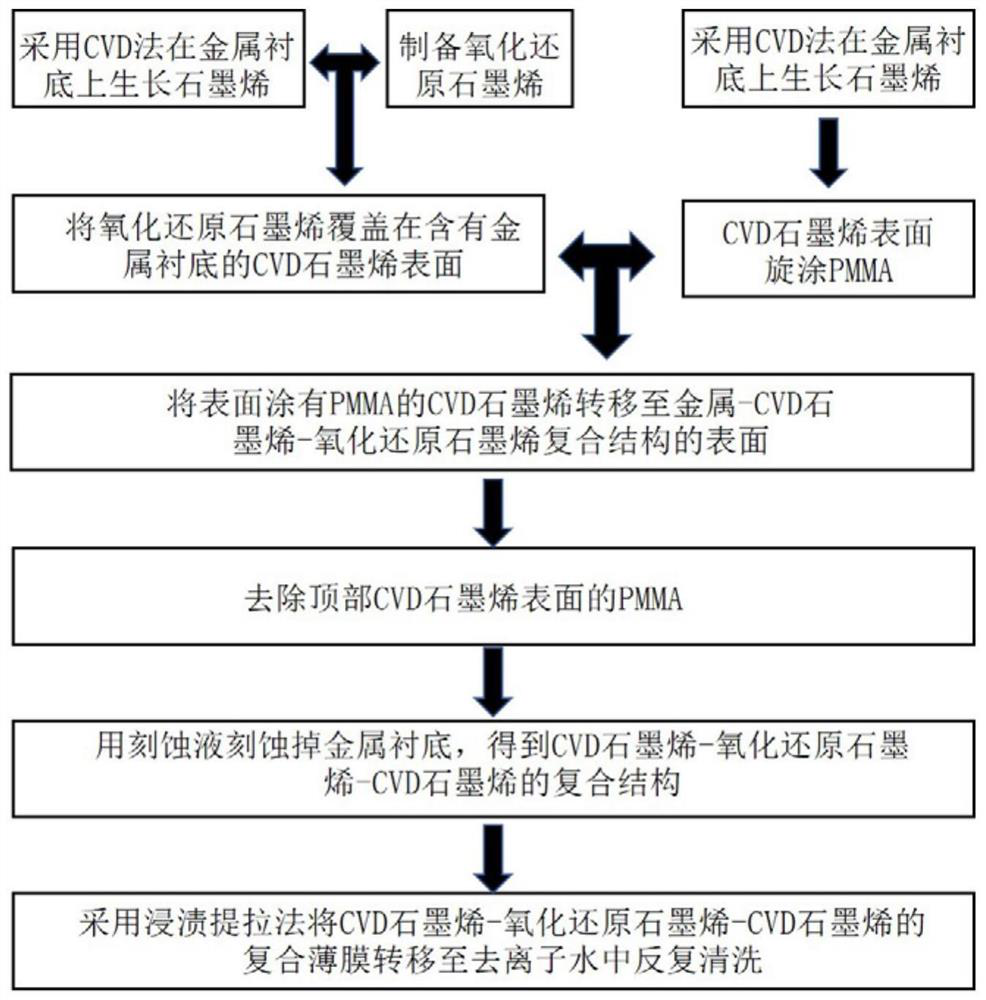

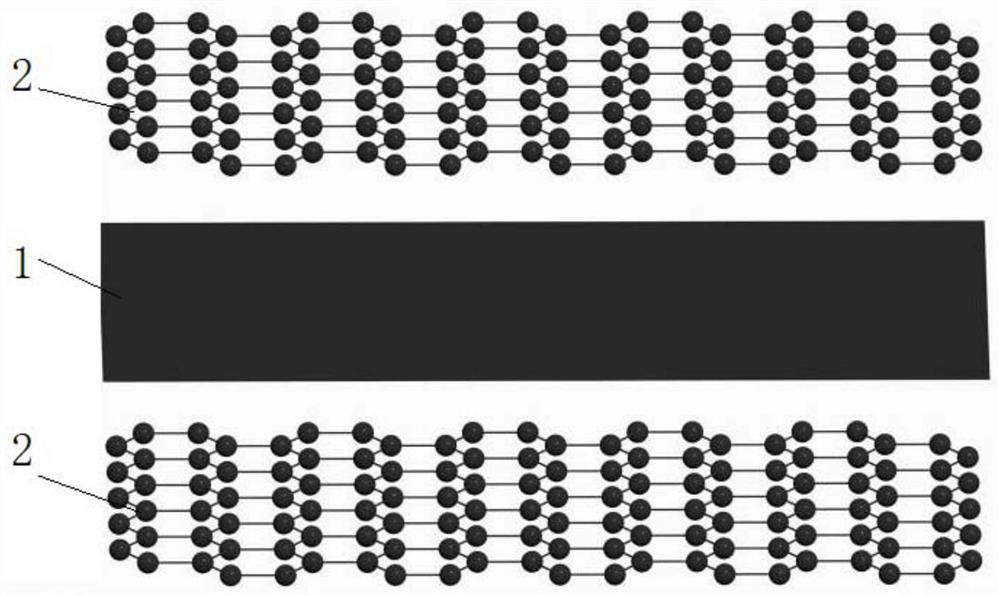

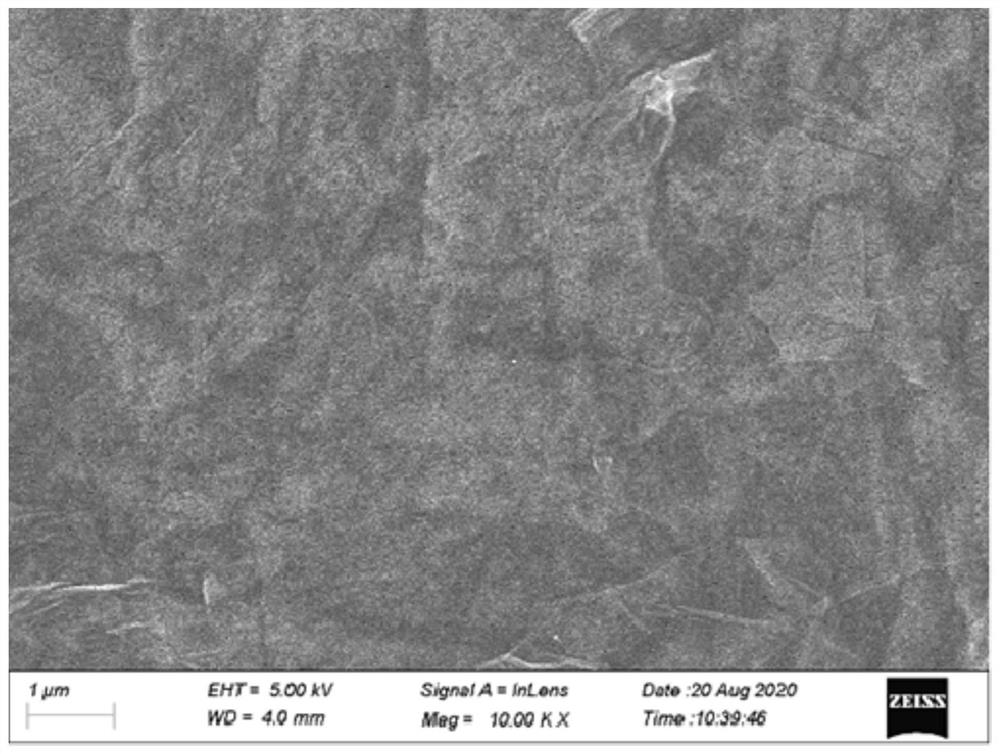

Sandwich structure heat dissipation film based on graphene, semiconductor device and preparation method thereof

PendingCN112490204ASimple processEasy to implementSemiconductor/solid-state device detailsSolid-state devicesDevice materialThin membrane

The invention discloses a sandwich structure heat dissipation film based on graphene, a semiconductor device, a preparation method thereof. The heat dissipation film comprises a redox graphene layer and CVD graphene layers, and the CVD graphene layers are arranged on the surfaces of the two sides of the redox graphene layer. The sandwich structure heat dissipation film based on graphene has good heat transfer capability in the direction parallel to or perpendicular to the substrate, so that the substrate or a semiconductor device can be subjected to rapid and uniform heat dissipation.

Owner:XI AN JIAOTONG UNIV

Bisphenol A epoxy resin modified bifunctional polyester acrylate UV (ultraviolet)-transparent primer for wooden furniture and preparation method thereof

ActiveCN104152017AOvercome the disadvantage of poor adhesionGood flexibilityPolyester coatingsPolyesterDrying time

The invention provides a bisphenol A epoxy resin modified bifunctional polyester acrylate UV (ultraviolet)-transparent primer for wooden furniture, which comprises the following components in percentage by weight: 30-55% of bifunctional polyester acrylate, 0.1-0.3% of wetting and dispersing agent, 0.3-0.5% of defoaming agent, 18-40% of filler, 8-20% of monomer, 0.3-0.6% of leveling agent, 1-3% of bisphenol A epoxy resin and 3-10% of initiator. The primer has the advantages of favorable color, favorable transparency, favorable glossiness, low cost, stable properties and high storability; and the primer film has the advantages of short drying time, favorable transparency, high glossiness, favorable fullness and excellent mechanical properties. The invention also provides a preparation method of the transparent primer. The method has the advantages of simple technique, simple operation, favorable repetitiveness, short production cycle and high production efficiency, and is very suitable for industrialized production.

Owner:FOSHAN GAOMING FULONGSI NEW MATERIAL TECH

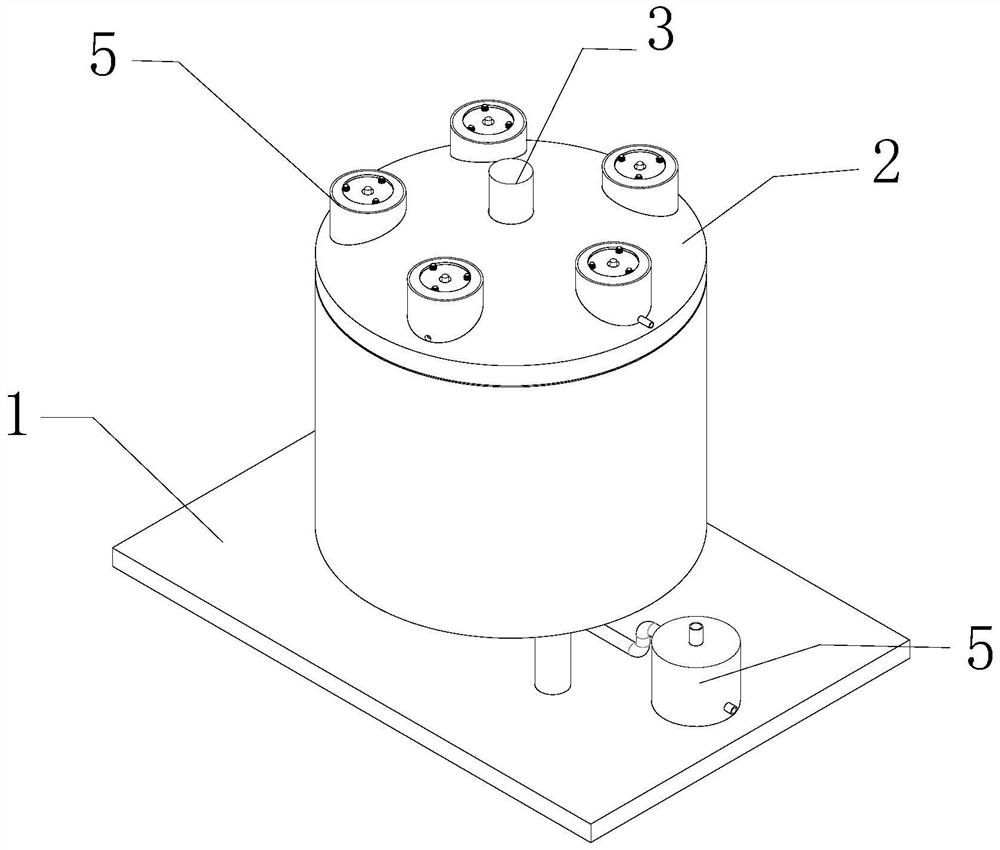

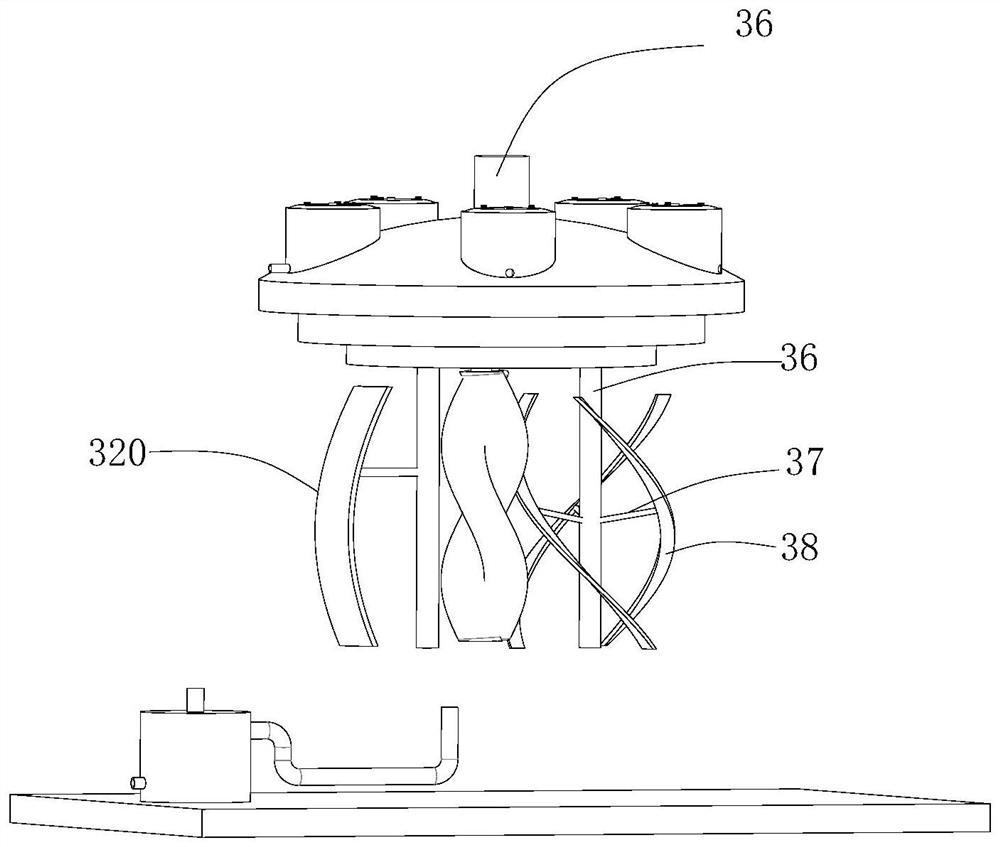

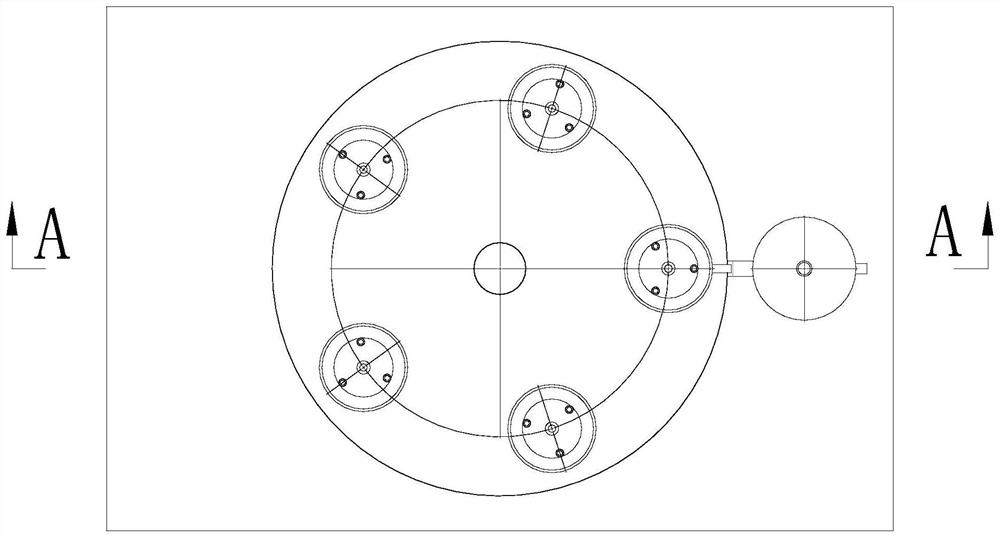

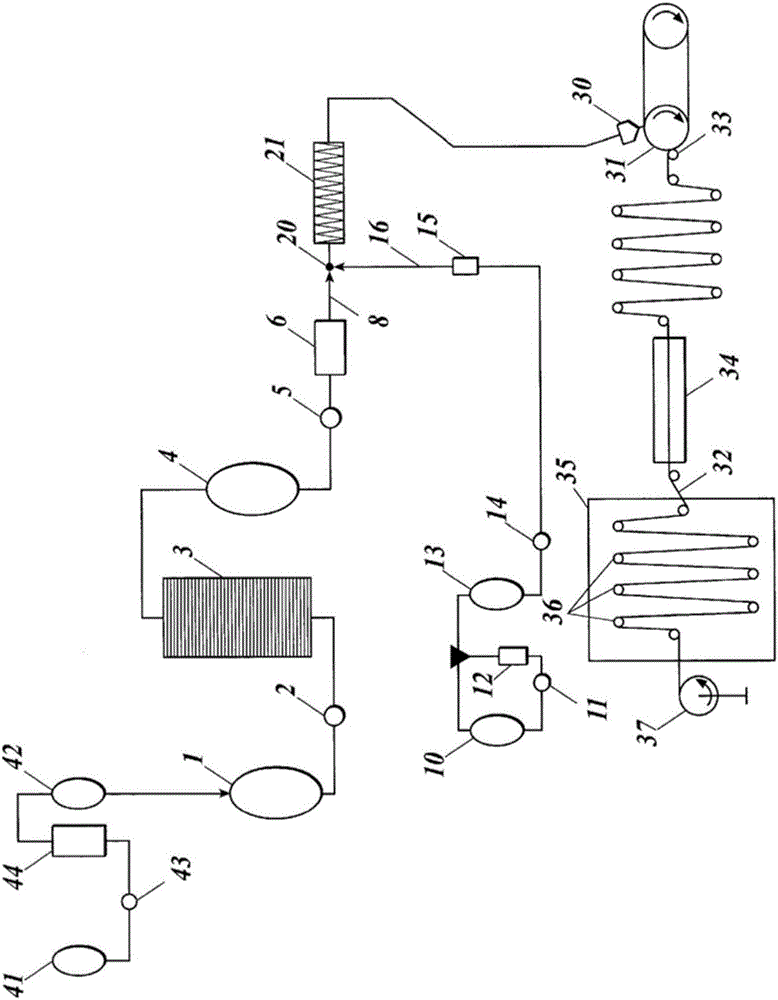

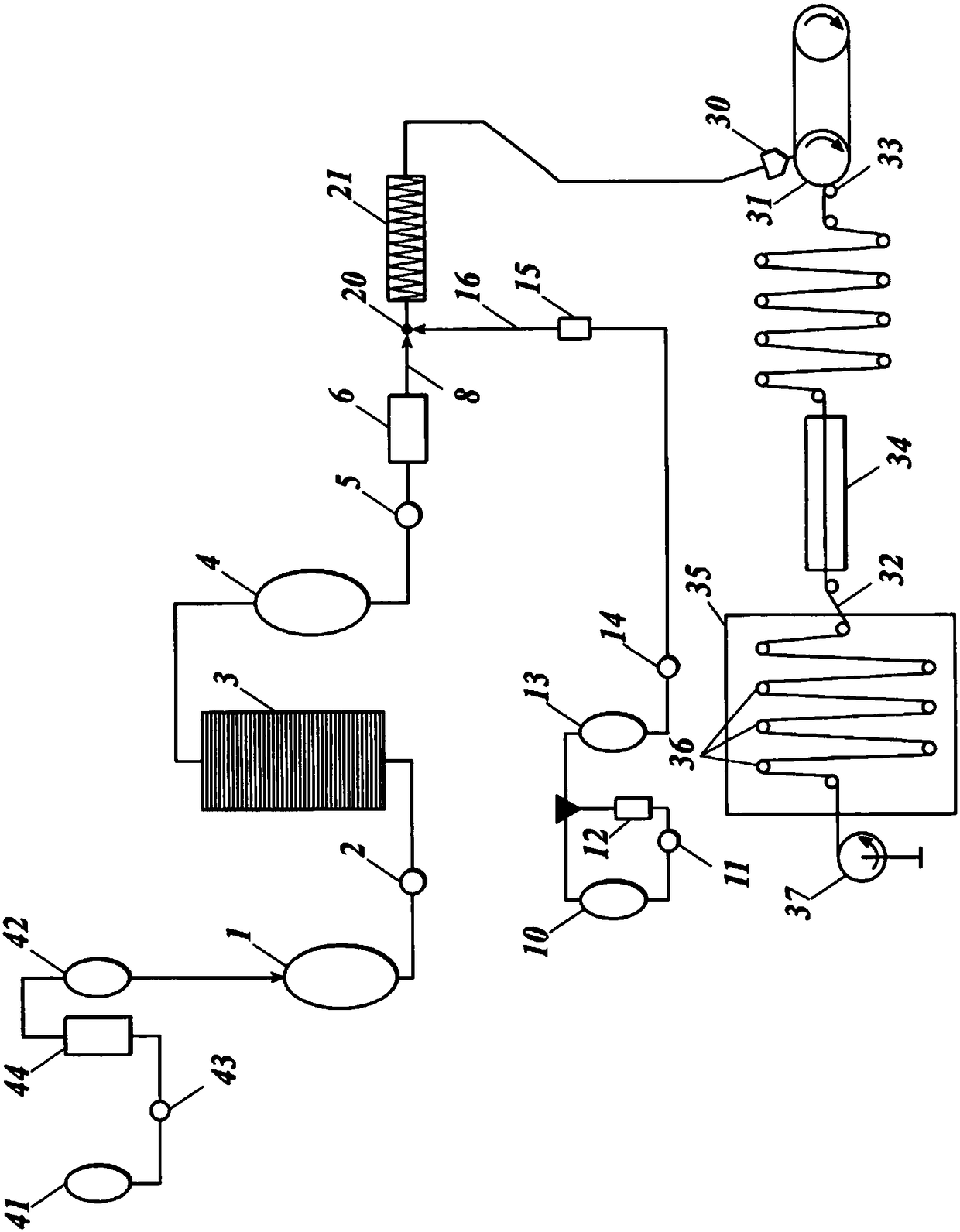

Epoxy modified silicon resin coating and preparation method thereof

InactiveCN112500790ANo reduction in temperature resistanceOptionalRotary stirring mixersTransportation and packagingEpoxyPolymer science

The invention discloses an epoxy modified silicon resin coating and a preparation method thereof. The coating is composed of base resin and a cross-linking agent according to the mass ratio of 100: (4-6). The preparation method comprises the following steps of: (1) preparing base resin: sequentially adding a monomer D, a monomer T and a silane coupling agent into a multi-functional stirrer, setting the stirring speed to be 100-300r / min, sequentially adding distilled water and a catalyst while stirring, adding a solvent after a reaction system releases heat, uniformly stirring and mixing, and standing for 12 hours to prepare a resin prepolymer, namely base resin; and (2) preparing the coating: uniformly mixing 100 parts of the base resin prepared in the step (1) and 4-6 parts of a cross-linking agent to obtain the waterborne epoxy modified silicon resin coating. The multi-functional stirrer in the step (1) comprises a damping base, fixed supporting legs, a tank body, a sealing cabin cover, a planetary stirring system, a feeding system and a bubble eliminating device. By means of the planetary stirring system, efficient stirring and accurate feeding of modified epoxy resin are achieved.

Owner:朱舒畅

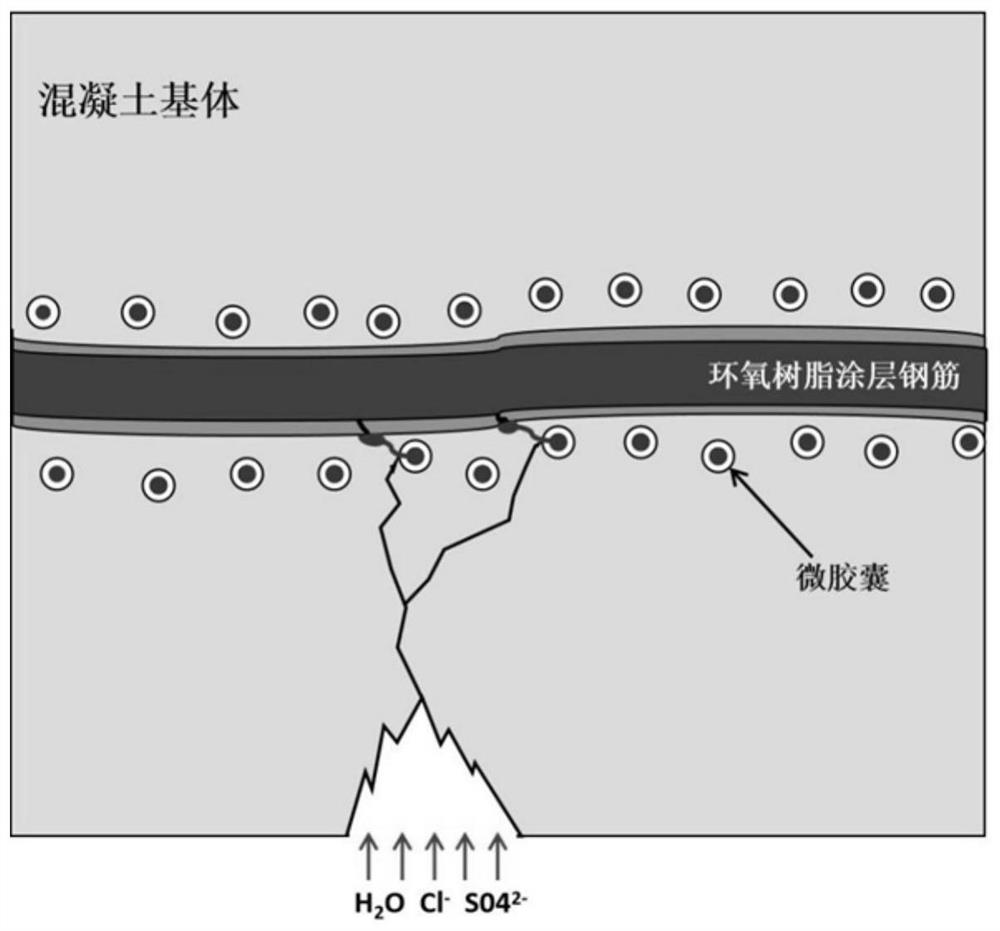

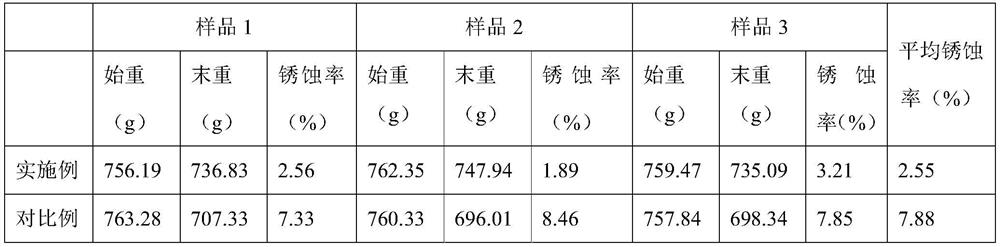

Concrete reinforcing steel bar corrosion prevention system based on microcapsule technology

ActiveCN113800828ABlock direct contactPrevent penetrationAnti-corrosive paintsEpoxy resin coatingsReinforced concreteCrazing

The invention discloses a concrete reinforcing steel bar anticorrosion system based on a microcapsule technology. The system comprises a concrete material and an epoxy resin coating reinforcing steel bar, wherein the concrete material is poured near the epoxy resin coating reinforcing steel bar, an epoxy resin curing agent is sprayed on the outer surface of the epoxy resin coating reinforcing steel bar, and a water-absorbing microcapsule with an epoxy resin as a core material is added into the concrete material. According to the invention, when a concrete matrix is cracked, water carrying harmful ions (Cl<-> and SO4<2->) continuously permeates along the crack propagation direction, the wall of a preset microcapsule near a reinforcing steel bar is broken due to the stress at the tip of the crack, and an epoxy resin flows out and meets a curing agent coated on the surface of the reinforcing steel bar, so that the surface of the reinforcing steel bar is cured and coagulated so as to prevent the direct contact between the epoxy coating steel bar and water and harmful ions, tand he wall of the microcapsule absorbs water and expands so as to block further permeation of water and harmful ions and protect the reinforcing steel bar from being rusted; and due to the use of the water-absorbing microcapsules, the binding power between the epoxy resin coated steel bar and concrete mortar is also improved.

Owner:山东省冶金产品质量监督检验站有限公司

Room temperature cured transparent inorganic water-resistant coating and preparation method thereof

InactiveCN109679386AImprove poor adhesionImprove adhesionAlkali metal silicate coatingsTetramethylammonium hydroxideGas phase

The invention discloses a room temperature cured transparent inorganic water-resistant coating and a preparation method thereof. The room temperature cured transparent inorganic water-resistant coating comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 10-15 parts of fumed silica, 20-25 parts of tetramethylammonium hydroxideand 60-70 parts of deionized water; and the component B comprises the following raw materials in parts by weight: 7-10 parts of lithium silicate, 75-85 parts of potassium silicate, 5-10 parts of KH-560 and 1-1.5 parts of ammonium dihydrogen phosphate. The room temperature cured transparent inorganic water-resistant coating provided by the invention solves problems of serious volatile pollution ofa traditional organic coating and relatively weak water resistance of an inorganic coating, has relatively good water resistance, can be cured at room temperature, is environmentally-friendly and pollution-free; and a cured coating film is strong in adhesion to workpiece, high in hardness, low in shrinkage rate, and excellent in weather resistance and fire retardancy.

Owner:ANHUI UNIVERSITY

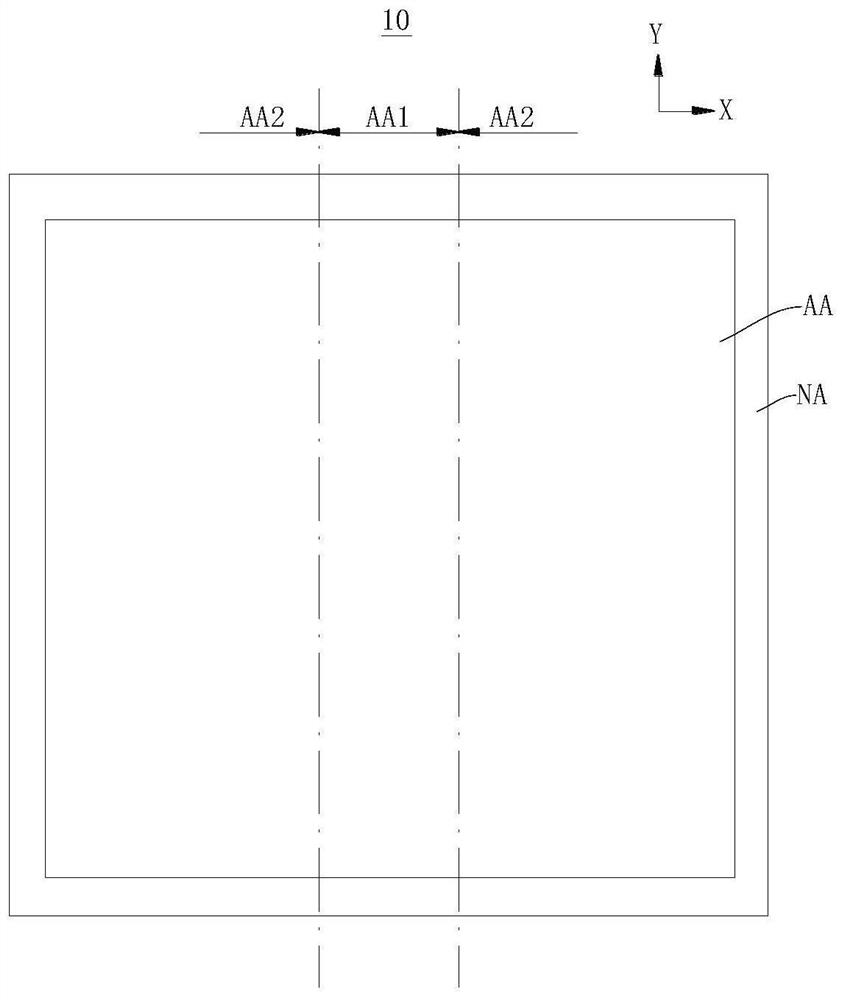

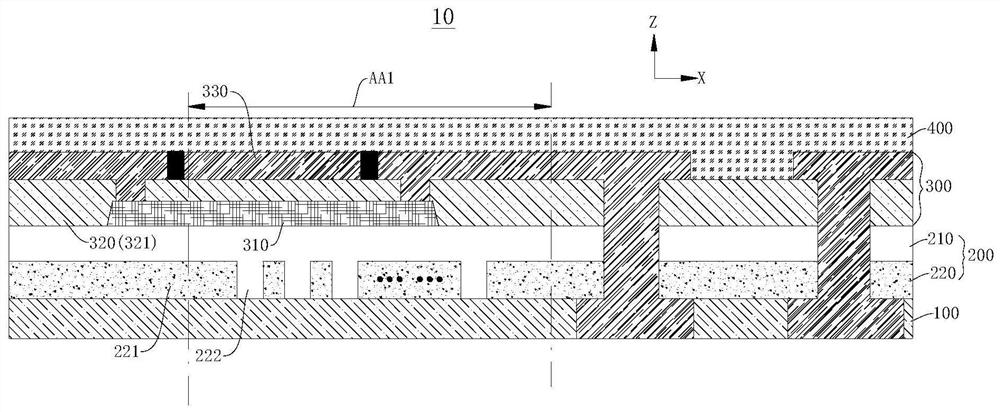

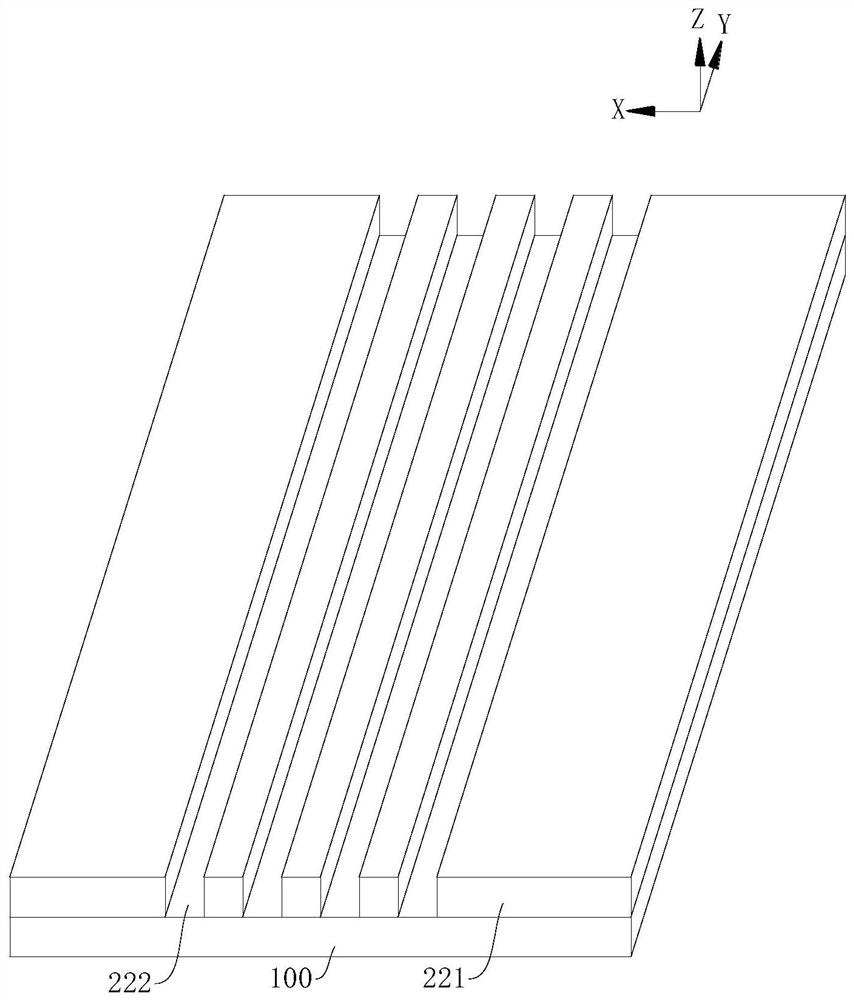

Display panel and display device

ActiveCN112531130AImprove bending performanceThe effect of improving bending propertiesFinal product manufactureSolid-state devicesComposite materialEngineering

The embodiment of the invention provides a display panel and a display device. The display panel is provided with a bending area and flattening areas located on the two sides of the bending area in the length direction of the display panel. The display panel comprises: a display structure layer; a first insulating layer which is located on one side of the display structure layer, wherein the firstinsulating layer comprises a first organic layer and a first inorganic layer which are arranged in a stacked mode, the first inorganic layer comprises a first body part and a first filling part, thestructural rigidity of the first filling part is smaller than that of the first body part, and the first filling part is located in the bending area; and a touch layer which is located on the side, away from the packaging layer, of the first insulating layer. According to the display panel provided by the embodiment of the invention, on the premise of ensuring good bending performance of the display panel, the problem of poor reliability caused by metal residues in the manufacturing process of the display panel can be improved.

Owner:HEFEI VISIONOX TECH CO LTD

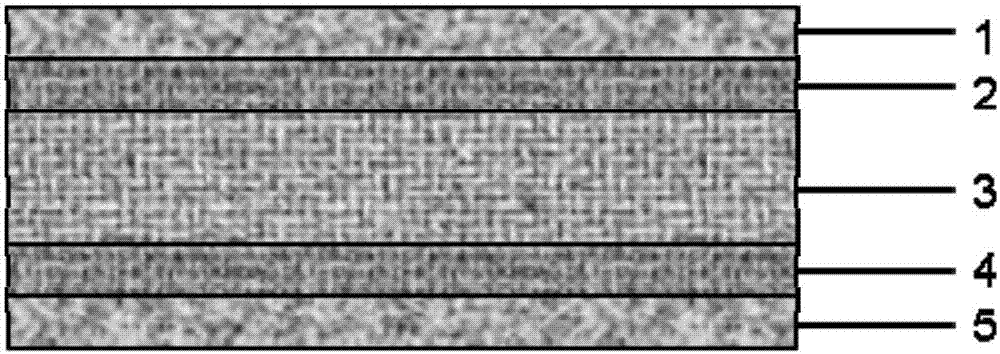

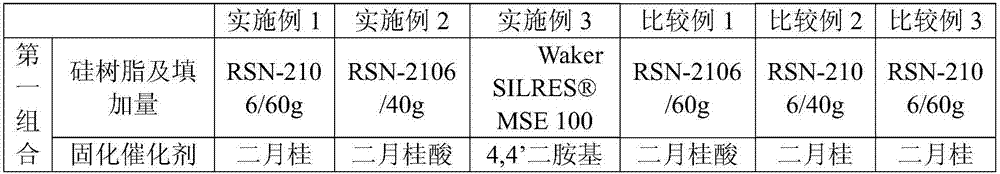

Polysiloxane composition laminated board and metal foil-coated laminated board thereof

PendingCN107303743AGood compatibilityHigh peel strengthSynthetic resin layered productsGlass/slag layered productsComposite materialMetal foil

The invention provides a polysiloxane composition laminated board and a metal foil-coated laminated board thereof. The laminated board comprises a three-layer structure, wherein a first layer is a first polysiloxane composition layer or a prepreg layer made of a first polysiloxane composition, a second layer is a prepreg layer made of a second polysiloxane composition, and a third layer is a third polysiloxane composition layer or a prepreg layer made of a third polysiloxane composition; the second layer is an intermediate layer, the first layer and the third layer are arranged at the upper side and the lower side of the second layer separately, wherein the thickness of the second layer is 75-95% of total thickness of the three-layer structure; the second layer is formed by a n addition type polysiloxane composition; the first layer and the third layer are formed by condensed and cured polysiloxane composition. The polysiloxane-based metal foil-coated laminated board is obtained through coating two sides of the laminated board with metal foils, and the metal foil-coated laminated board has relatively high peel strength and excellent voltage resistance and dielectric property.

Owner:GUANGDONG SHENGYI SCI TECH

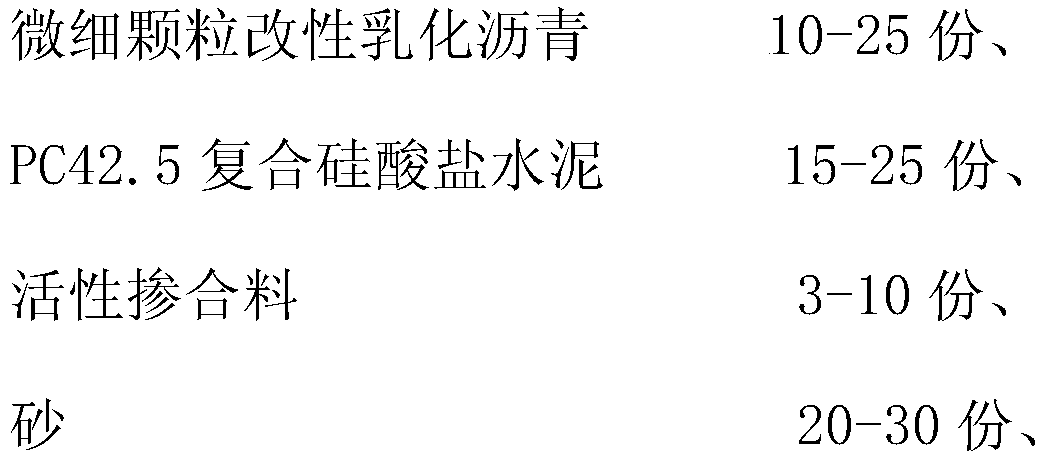

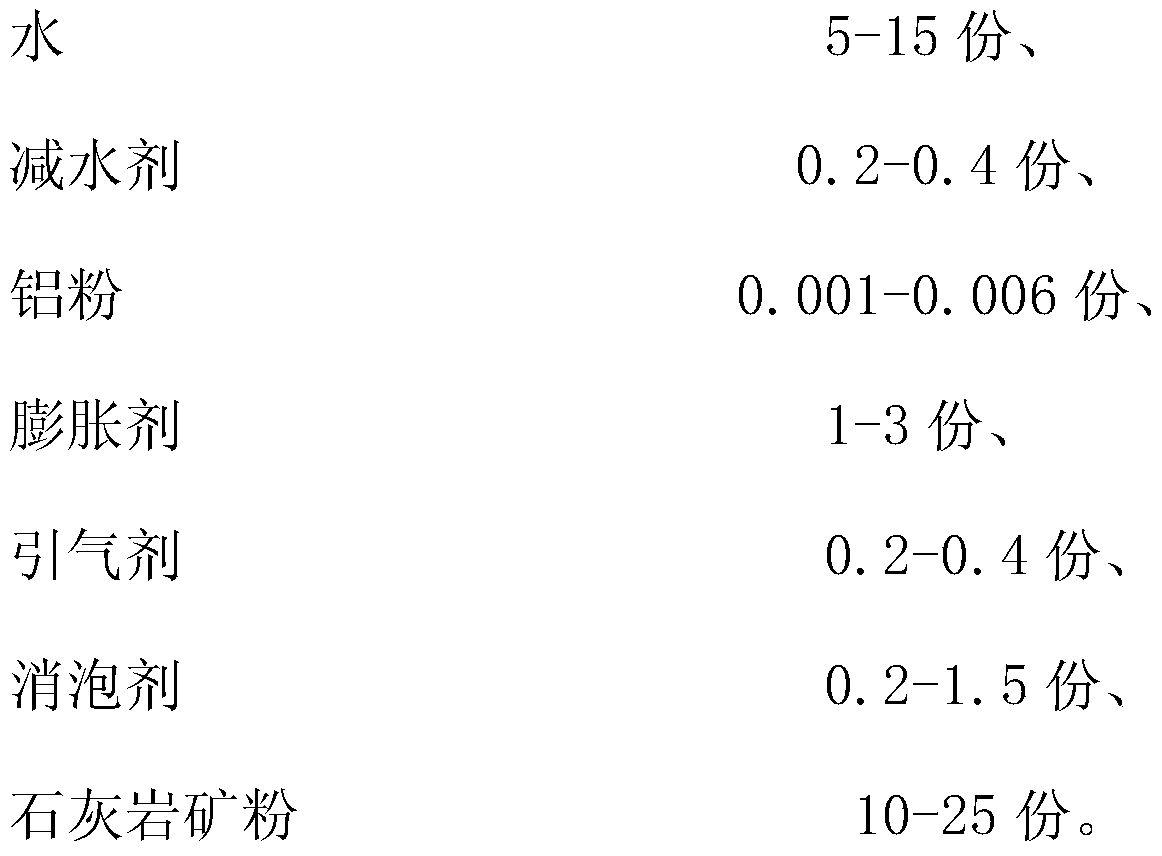

Semi-rigid asphalt pavement material and preparation method thereof

ActiveCN106186922BReduce high temperature viscosityIncrease high temperature viscosityCeramicwareCrack resistancePavement engineering

The invention relates to a pavement engineering material, and concretely relates to a semi-rigid asphalt pavement material and a preparation method thereof. The semi-rigid asphalt pavement material comprises, by volume, 75-85% of a macro-porous asphalt mixture and 15-25% of a grouting material; the macro-porous asphalt mixture is obtained through mixing mineral, a filler and rubber high-viscosity modified asphalt; and the grouting material is obtained through mixing fine particle modified emulsified asphalt, PC42.5 composite Portland cement, an active admixture, sands, water, a water reducer, an aluminum powder, an expanding agent, an air entraining agent, an antifoaming agent and limestone mineral powder. The semi-rigid asphalt pavement material has the advantages of good construction workability, strong high-temperature rut resistance and low-temperature cracking resistance, good durability, long fatigue life, good combination property of the macro-porous asphalt mixture with the grouting material, small temperature shrinkage and dry shrinkage cracks, energy saving, environmental protection, and realization of the high cost performance of recycling of solid wastes.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

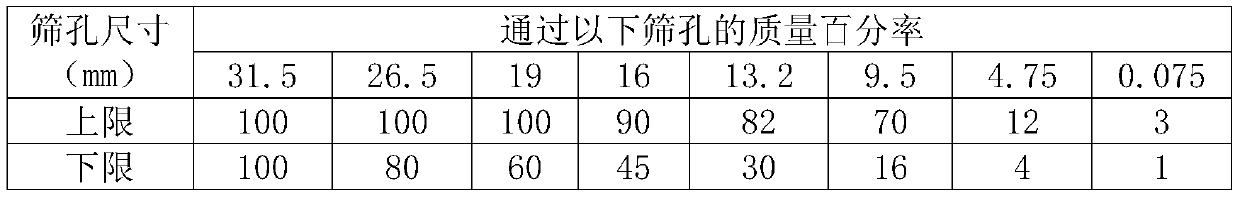

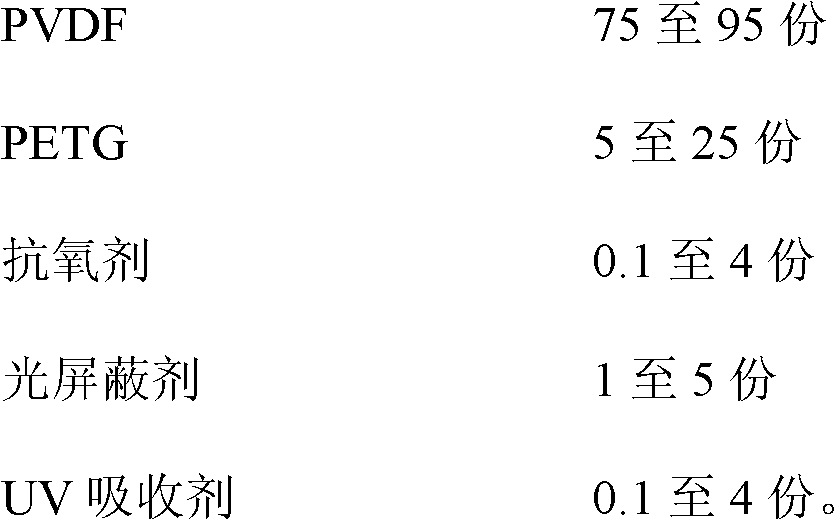

PVDF/PETG composite and film for preparing same

The invention discloses a PVDF / PETG composite. The composite is high in compatibility. The composite consists of the following components in part by weight: 70 to 100 parts of PVD, 1 to 30 parts of PETG, 0.1 to 5 parts of antioxidant, 0.1 to 5 parts of light screener and 0.1 to 5 parts of UV absorbent.

Owner:NANJING TECH UNIV

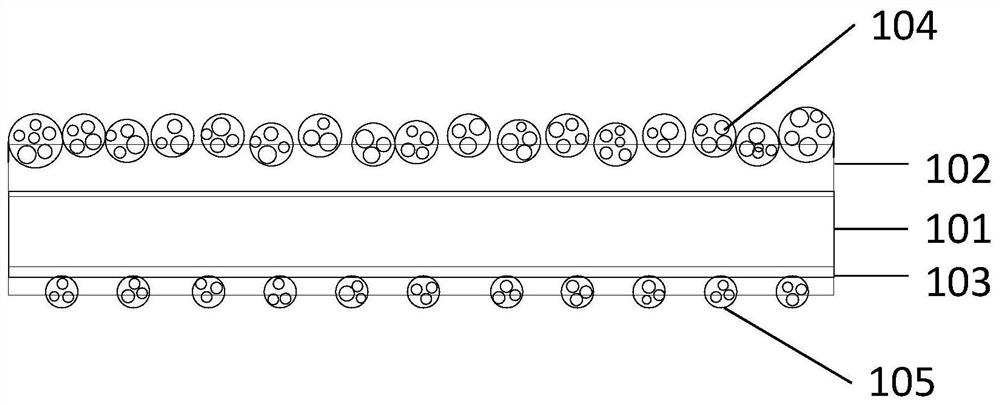

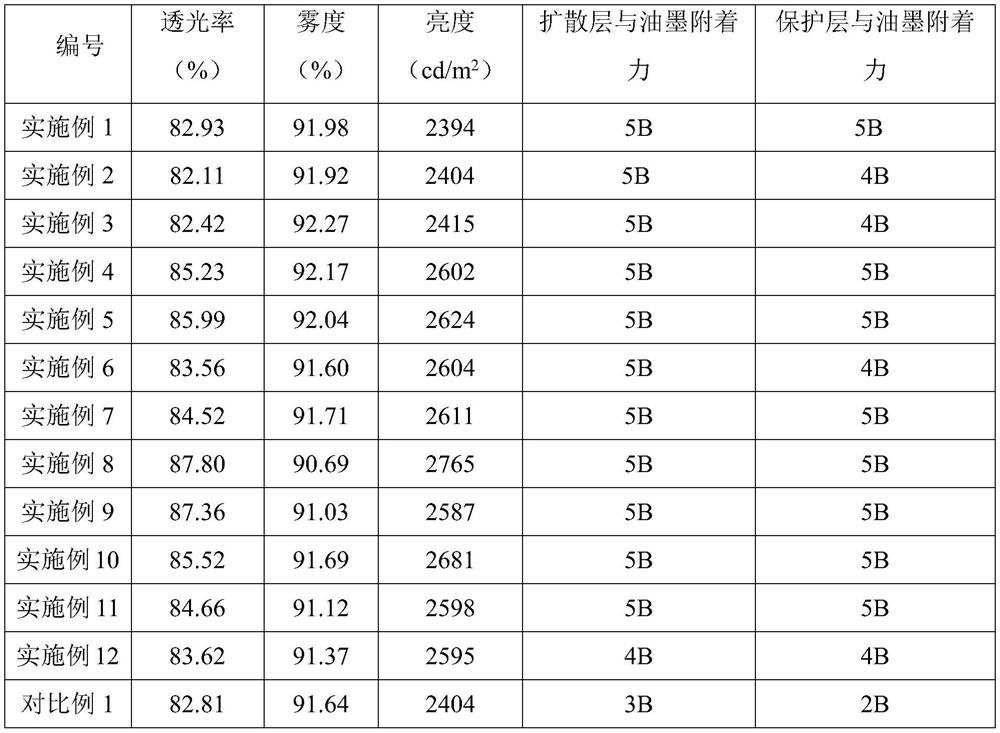

A kind of diffusion film and its application

ActiveCN109375302BIncrease surface tensionImprove poor adhesionDiffusing elementsNon-linear opticsCoated surfacePrinting ink

The invention relates to the field of optical thin films, and more specifically relates to a novel optical diffusion film suitable for ink printing and a preparation method thereof. In order to solve the problem of poor adhesion between the diffusion film and the ink coating after the existing diffusion film is printed with ink, the invention provides a diffusion film and a preparation method thereof. The diffusion film includes a transparent substrate, a diffusion coating and a protective coating; the diffusion coating and the protective coating are respectively located on the upper and lower surfaces of the transparent substrate. The diffusion coating comprises diffusion porous particles. The protective coating comprises anti-blocking porous particles. The diffusion film suitable for ink printing provided by the present invention not only has excellent diffusion effect, covering property and optical performance, but at the same time, due to the addition of porous particles in the coating of the diffusion film, the specific surface area of the coating surface is greatly increased, thereby increasing the surface area of the coating. After ink printing, the problem of poor coating adhesion is obviously improved, and the preparation method is simple in process and easy to operate.

Owner:NINGBO EXCITON TECH

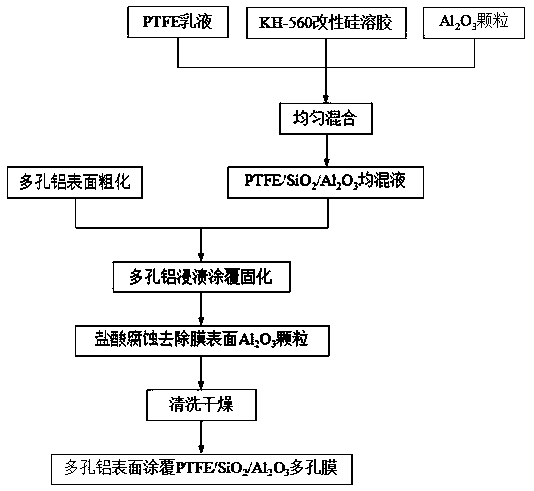

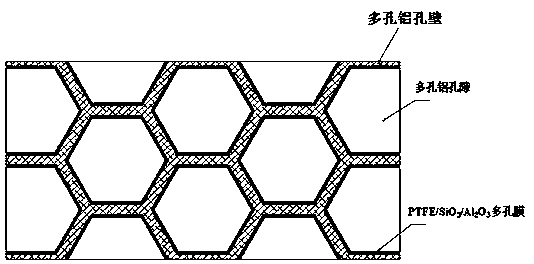

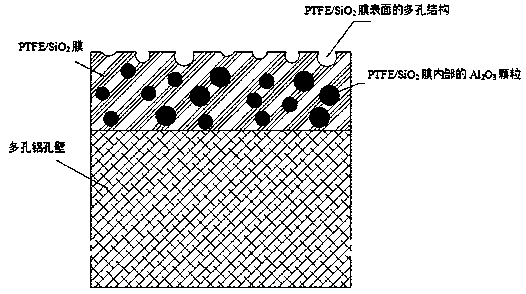

Preparation method of PTFE/SiO2/Al2O3 porous membrane coated on surface of porous aluminum

ActiveCN109332137ASimple processImprove preparation efficiencyPretreated surfacesCoatingsPorous membraneEmulsion

The invention discloses a preparation method of a PTFE / SiO2 / Al2O3 porous membrane coated on the surface of porous aluminum, and belongs to the technical field of porous metal material surface treatment. The preparation method comprises the steps of adopting a PTFE emulsion, a KH-560 modified silica sol and Al2O3 particles as raw materials, and uniformly mixing the raw materials according to the matching ratio so as to obtain a uniform PTFE / SiO2 / Al2O3 mixed solution; secondly, dipping the surface-roughened porous aluminum in the PTFE / SiO2 / Al2O3 mixed solution, coating, curing, and obtaining a PTFE / SiO2 / Al2O3 film layer with the thickness being 40 to 60mum on the surface of the porous aluminum; and finally, using hydrochloric acid for corroding and removing the Al2O3 particles exposed on thePTFE / SiO2 / Al2O3 membrane layer on the surface of the porous aluminum, and forming the PTFE / SiO2 / Al2O3 porous membrane with the surface porosity being 5 to 40 percent and the surface aperture being 1to 10mum on the surface of the porous aluminum. The PTFE / SiO2 / Al2O3 porous membrane coated on the surface of the porous aluminum prepared through the invention is high in specific surface area, controllable in surface hole structure, good in corrosion resistance and hydrophobicity, simple in preparation process, and capable of realizing industrial production.

Owner:KUNMING UNIV OF SCI & TECH

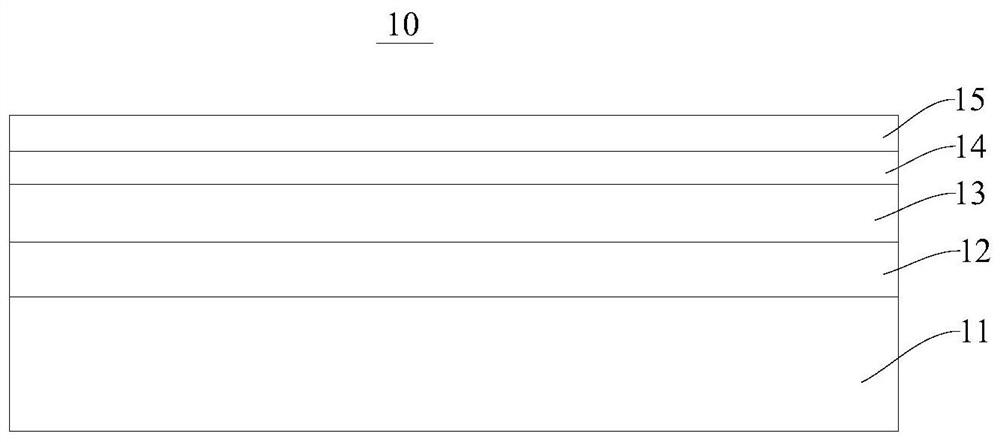

Anodized aluminum foil and preparation method thereof

ActiveCN112497946BImprove adhesionStrong adhesionDecorative surface effectsOther printing apparatusAcrylic resinAcrylate ester

An anodized aluminum foil and a preparation method thereof relate to the technical field of anodized aluminum foil. The anodized aluminum foil includes a base film, a release layer, an imaging layer, a protective layer and an aluminum layer that are stacked in sequence. The imaging layer includes a first resin and a dye, the first resin is an acrylic resin, the protective layer includes a second resin, and the second resin is an acrylate-acrylic copolymer. The protective layer of the anodized aluminum foil of the present application has good adhesion to the aluminum layer and the imaging layer, which improves the problem of poor adhesion between the imaging layer and the aluminum layer.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Water-based gravure prime coat ink

The invention relates to the technical field of new materials, in particular to water-based gravure prime coat ink, which is prepared from the following raw materials in percentage by mass: 60 to 90 percent of styrene-acrylic acid copolymer emulsion, 0 to 30 percent of pigment color paste, 10 to 20 percent of edible alcohol, 0.5 to 1 percent of polyethylene wax, 15 to 25 percent of water and 0.2 to 0.4 percent of defoaming agent. The primer ink is full in color and luster, high in transparency, good in adhesive force and good in printing adaptability; the printing ink can be prepared into base coats with various colors according to requirements, and can be suitable for printing of a high-speed gravure press, the adhesion fastness of a printed product after being discharged from the press reaches 95% or above, the printing effect is attractive and elegant, and the problem that part of printing ink is poor in adhesion on aluminized paper can be remarkably solved.

Owner:湖南金固力油墨涂料有限公司

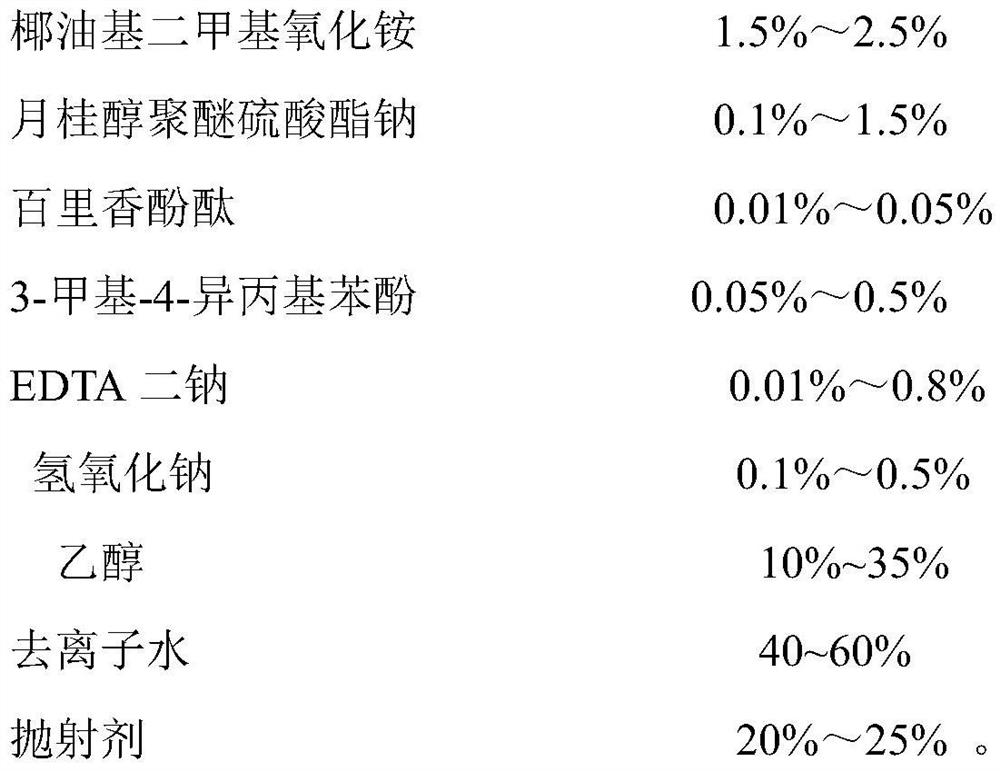

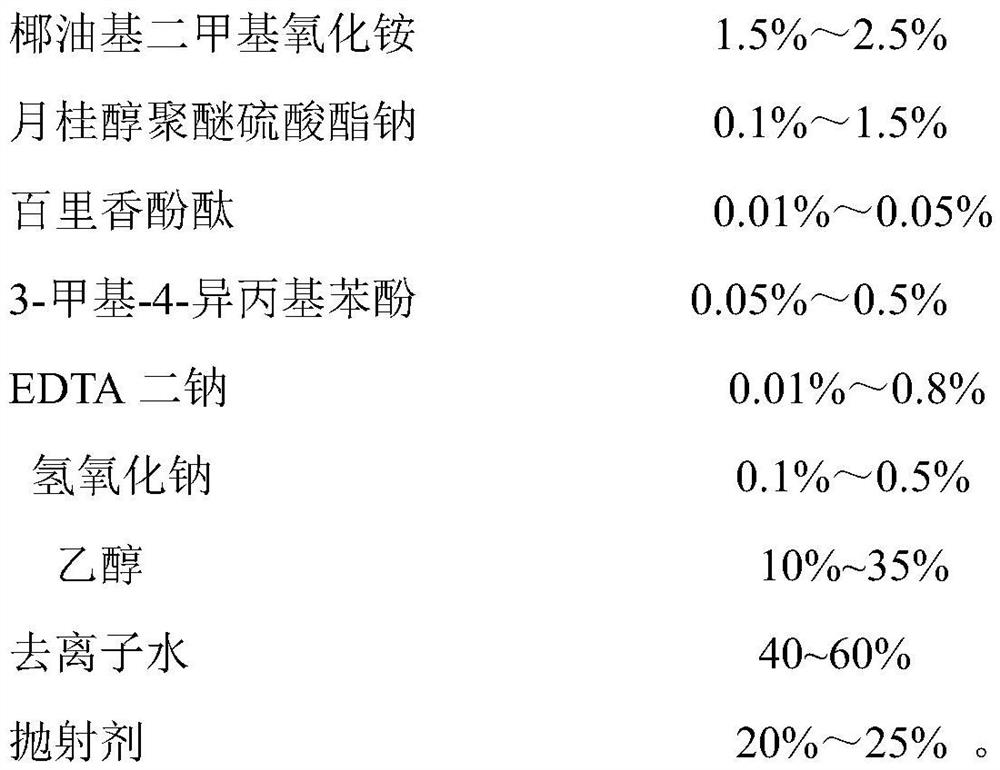

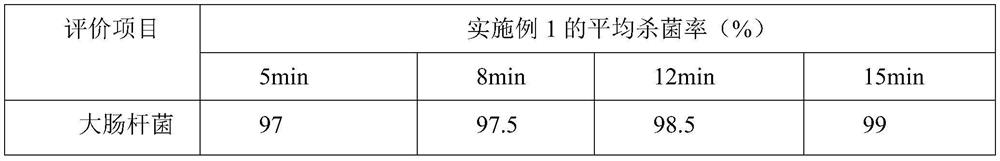

Closestool bubble cleaning agent and preparation method thereof

PendingCN113652313AStrong erosionImprove poor adhesionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCleansing AgentsPhenol

The invention relates to the technical field of cleaning agents, in particular to a closestool bubble cleaning agent and a preparation method thereof. The closestool bubble cleaning agent is prepared from the following components in percentage by weight: 1.5%-2.5% of coco-dimethyl ammonium oxide, 0.1%-1.5% of sodium laureth sulfate, 0.01%-0.05% of thymol phenolphthalein, 0.05%-0.5% of 3-methyl-4-isopropyl phenol, 0.01%-0.8% of disodium EDTA (Ethylene Diamine Tetraacetic Acid), 0.1%-0.5% of sodium hydroxide, 10%-35% of ethanol, 40-60% of deionized water and 20%-25% of a propellant. The closestool bubble cleaning agent has the advantages of less peculiar smell, large coverage area, good adhesion strength and visual cleanliness. According to the preparation method of the closestool bubble cleaning agent, a target product can be prepared through simple mixing, and the preparation method has the advantage of being easy to operate.

Owner:广东莱雅新化工科技有限公司

Cellulose-ester film, manufacturing method therefor, and polarizing plate

ActiveCN105849599AExcellent phase difference displayGood adhesionPolarising elementsCoatingsCellulose ester membraneAcetic acid

This invention addresses the problem of providing the following: a thin cellulose-ester film that performs well at producing a phase difference and adheres well to a polarizer via either a PVA-based liquid glue or a UV-curable adhesive; a method for manufacturing said cellulose-ester film; and a polarizing plate. Said cellulose-ester film, which contains, at least, cellulose acetate (resin A) having an acetyl-group substitution degree in the 2.1-2.6 range and a retardation-increasing agent, is characterized in that the contact angle between pure water and the surface of the cellulose-ester film is in the 30-75 degrees range, measuring said contact angle at 20 equally spaced points in the widthwise direction of the film yields a standard deviation in the 0.05-3.0 degrees range, and the transmittance of the cellulose-ester film at a wavelength of 320 nm is at least 80%.

Owner:KONICA MINOLTA INC

A type of wooden furniture with bisphenol -type epoxy resin modifiers dual -agglomerate acrylate UV transparent primer and preparation method

Owner:FOSHAN GAOMING FULONGSI NEW MATERIAL TECH

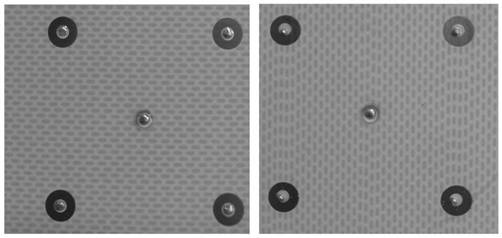

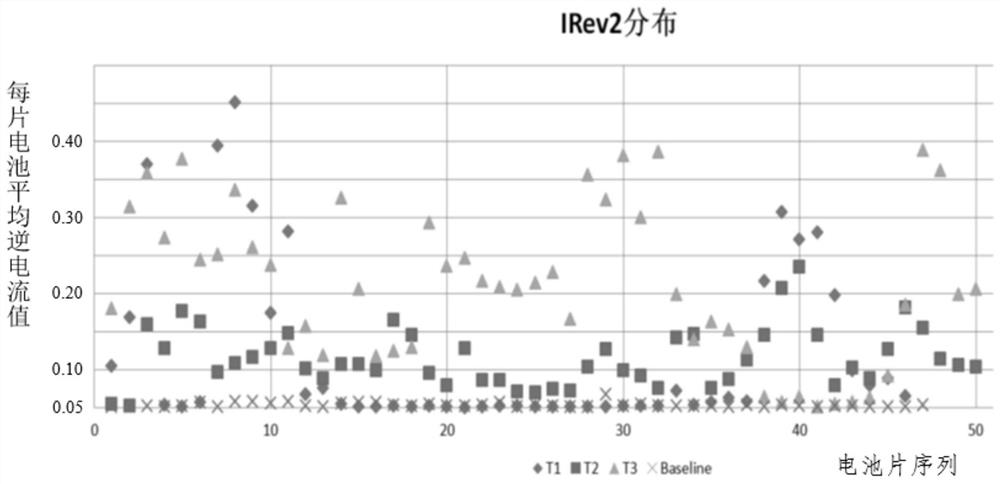

MWT cell, MWT cell hole filling slurry, frit and frit raw material composition

InactiveCN112382674AImprove adhesionAvoid damagePhotovoltaic energy generationSemiconductor devicesFritSilicon solar cell

The invention relates to the field of metal perforated winding silicon solar cells, in particular to an MWT cell, MWT cell hole filling slurry, frit and frit raw material composition. The compositionfor preparing MWT cell hole filling slurry frit mainly comprises the following components in parts by weight: 60-80 parts of P2O5, 1-8 parts of CuO, 2-8 parts of MgO, 4-10 parts of CaO, 3-8 parts of SiO2 and 1-6 parts of K2O. The corrosion capability of the phosphate glass is weak, so that an over-etching phenomenon can be avoided, a PN junction is prevented from being damaged to cause electric leakage, and no influence is caused to steady-state electric leakage. CuO can effectively improve the wettability of the glass, so that a good tin soldering effect is achieved. When the frit prepared through mutual compatibility of all the substances is used for the MWT battery hole-pouring slurry, the adhesive force of the hole-pouring slurry can be improved, and the cured slurry is prevented fromfalling off.

Owner:DK ELECTRONICS MATERIALS INC

Cellulose ester film, method for producing same, and polarizing plate

ActiveCN105849599BExcellent phase difference displayGood adhesionPolarising elementsCoatingsCellulose ester membraneAcetic acid

The technical problem of the present invention is to provide a polarizer that has excellent adhesiveness when using both PVA-based glue and ultraviolet-curable adhesive, and is a thin film and exhibits phase difference. Excellent cellulose ester film, its production method and polarizing plate. The cellulose ester film of the present invention is a cellulose ester film containing at least cellulose acetate (resin A) with a degree of substitution of acetyl groups in the range of 2.1 to 2.6 and a retardation increasing agent, wherein the cellulose ester film surface The contact angle of pure water is in the range of 30° to 75°, and the standard deviation when the contact angle is measured at 20 points at equal intervals in the film width direction is in the range of 0.05° to 3.0°, and the cellulose ester film The light transmittance at a wavelength of 320 nm is 80% or more.

Owner:KONICA MINOLTA INC

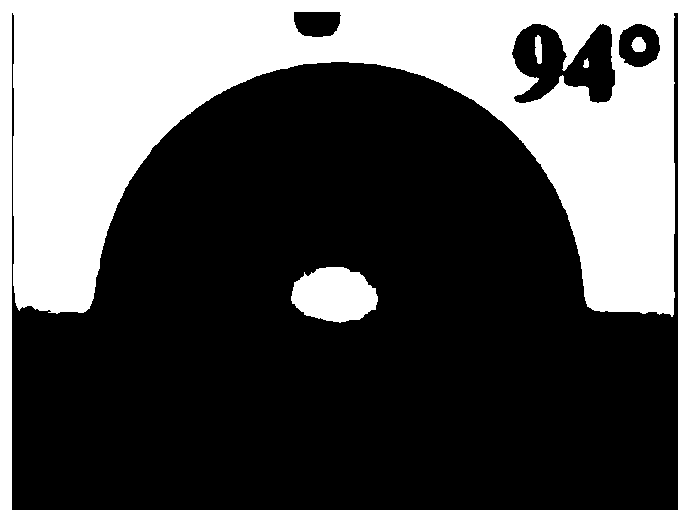

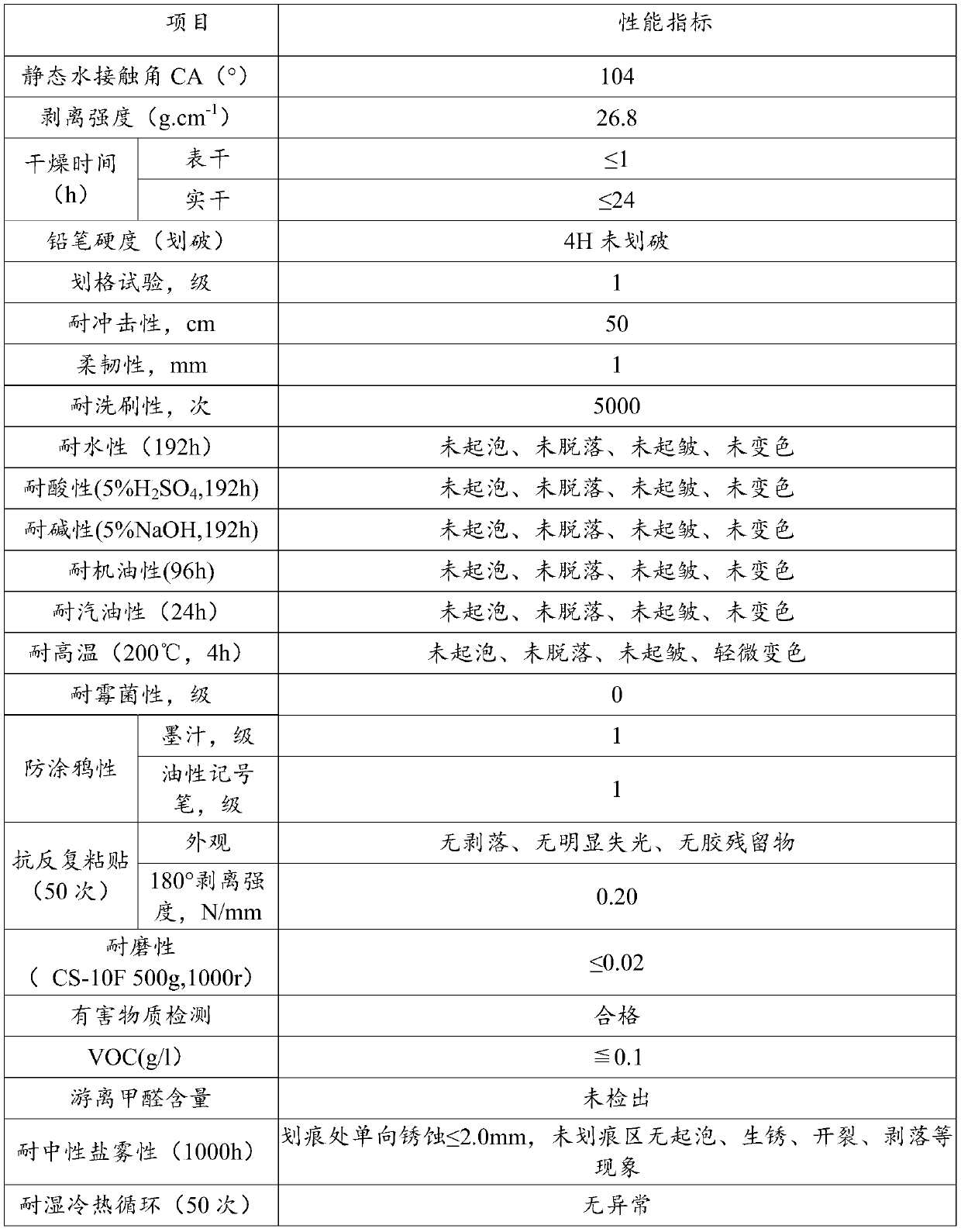

Stain-resistant high-temperature-resistant water-based coating and preparation method thereof

InactiveCN110724414AImprove poor adhesionImprove stain resistanceFireproof paintsAntifouling/underwater paintsPolymer sciencePolyether polyurethane

The invention discloses a stain-resistant high-temperature-resistant water-based coating. The coating comprises the following components in parts by weight: 30-50 parts of a water-based fluorocarbon emulsion, 10-20 parts of a self-crosslinked organic silicon grafted and modified pure acrylic emulsion, 15-30 part of a solvent, 2-5 part of a filler, 1-2 part of a coalescing agent, 0.3-0.8 part of apolyether polyurethane thickening rheological agent, 0.4-0.6 part of a dispersant, 0.2-0.5 part of an organic silicon defoamer, 0.1-0.6 part of an antiseptic antimildew agent, 0.1-0.3 part of a thickener, 0.1-0.3 part of a wetting agent and 0.1-0.2 part of ammonia water. The static water contact angle of a paint film formed by a single aqueous fluorocarbon emulsion is about 90 degrees. However, after the self-crosslinked organic silicon grafted and modified pure acrylic emulsion and the water-based fluorocarbon emulsion with a suitable proportion are adopted in the invention, fluorine and silicon elements migrate to the surface of the paint film, and the static water contact angle rises to 104 degrees, so that stain resistance performance is greatly improved, and a problem of poor adhesionof a pure fluorocarbon emulsion is improved at the same time.

Owner:武汉长弢新材料有限公司

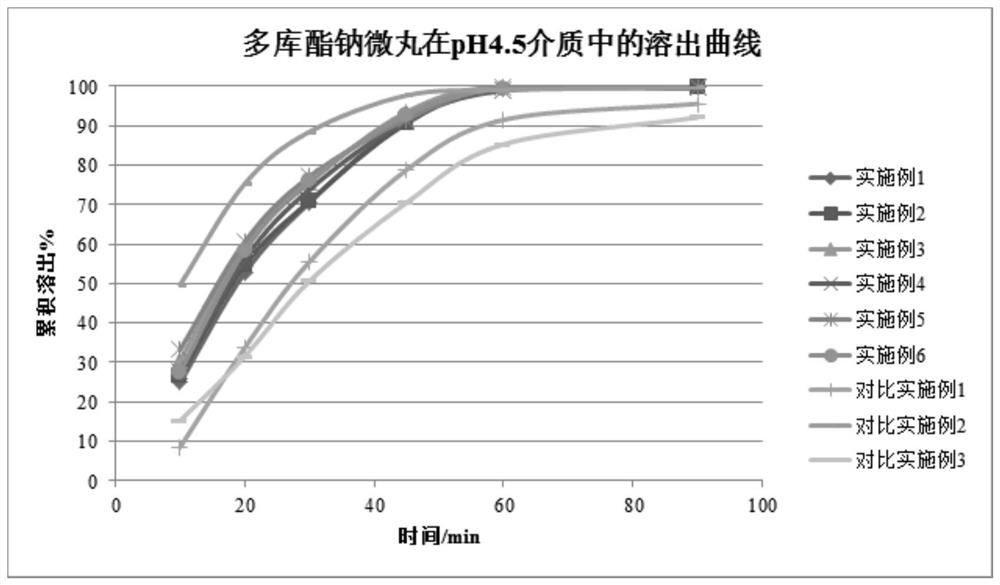

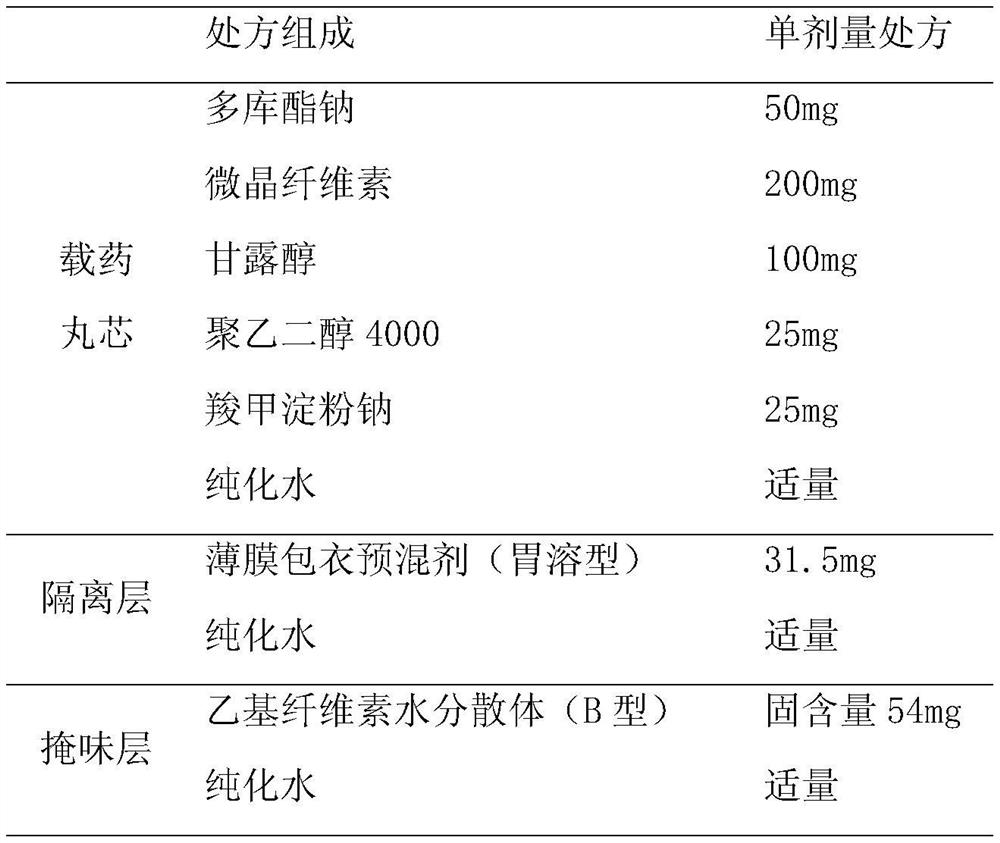

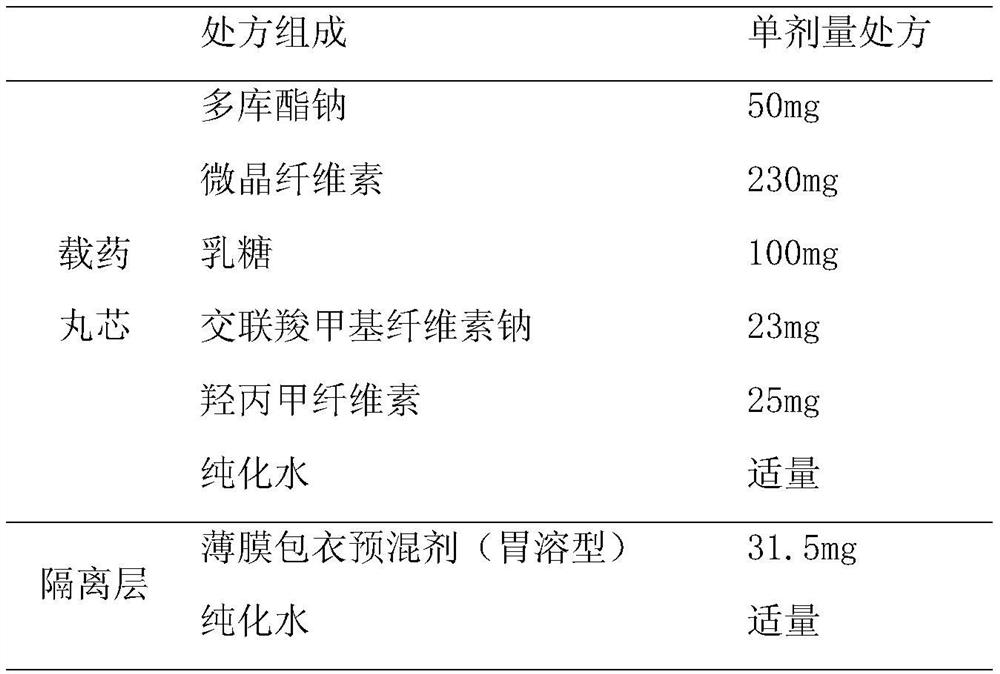

Docusate sodium pellet and preparation method thereof

InactiveCN112675146AUniform colorFlat surfaceDigestive systemPharmaceutical non-active ingredientsFluidized bedDocusate Sodium

The invention discloses a docusate sodium pellet and a preparation method thereof. The docusate sodium pellet sequentially comprises a drug-loaded pellet core, an isolation layer and a taste masking layer from inside to outside. The docusate sodium pellet is prepared from docusate sodium and pharmaceutically acceptable auxiliary materials, wherein a filler accounts for 60-95% of the weight of the drug-loaded pellet core; a disintegrating agent accounts for 3-8% of the weight of the drug-loaded pellet core; a cosolvent and an adhesive can be added as required; the coating weight of the isolation layer is increased by 4%-9%; and the weight of the taste masking layer coating is increased by 7-15%. Extrusion-rounding pellet preparation and fluidized bed coating technologies are adopted in the invention. The docusate sodium pellet disclosed by the invention is stable in quality and uniform in in-vitro dissolution; and the bitterness and astringency of docusate sodium can be effectively masked, and the medicine taking compliance is improved.

Owner:HUNAN WARRANT PHARMA

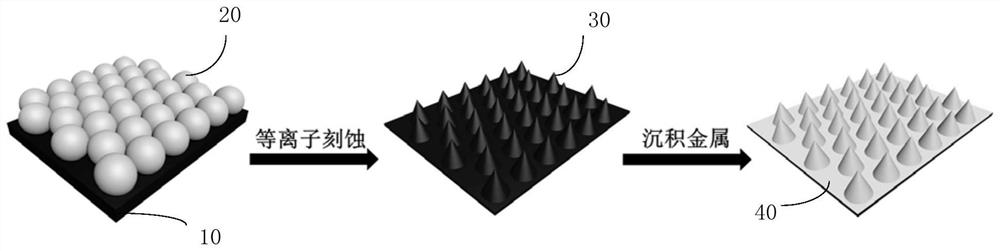

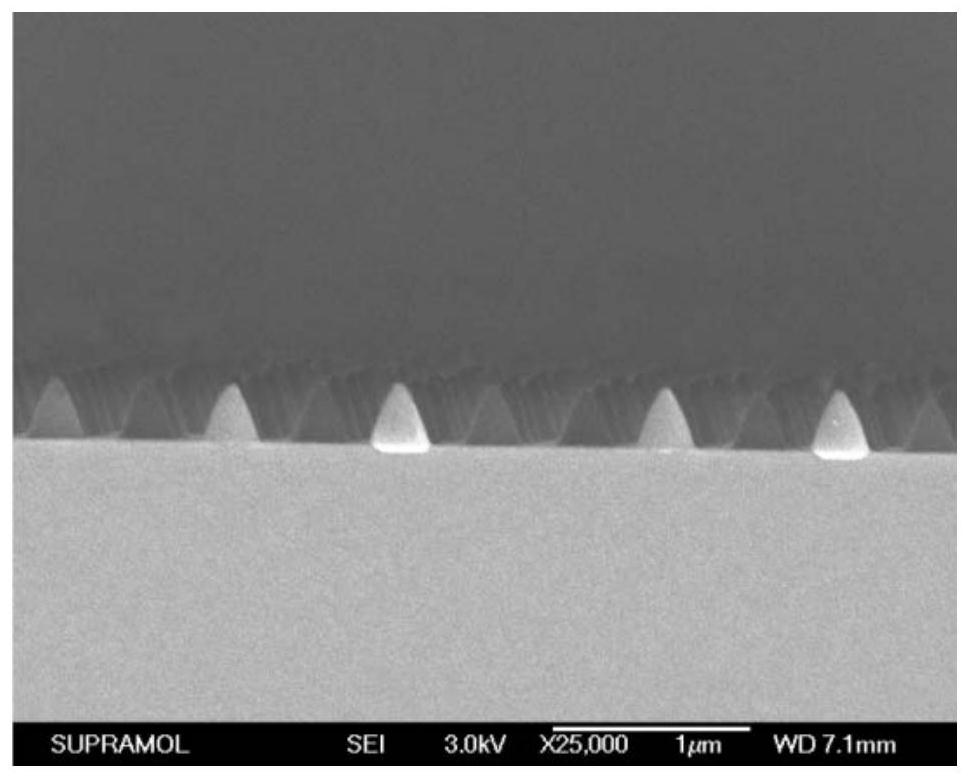

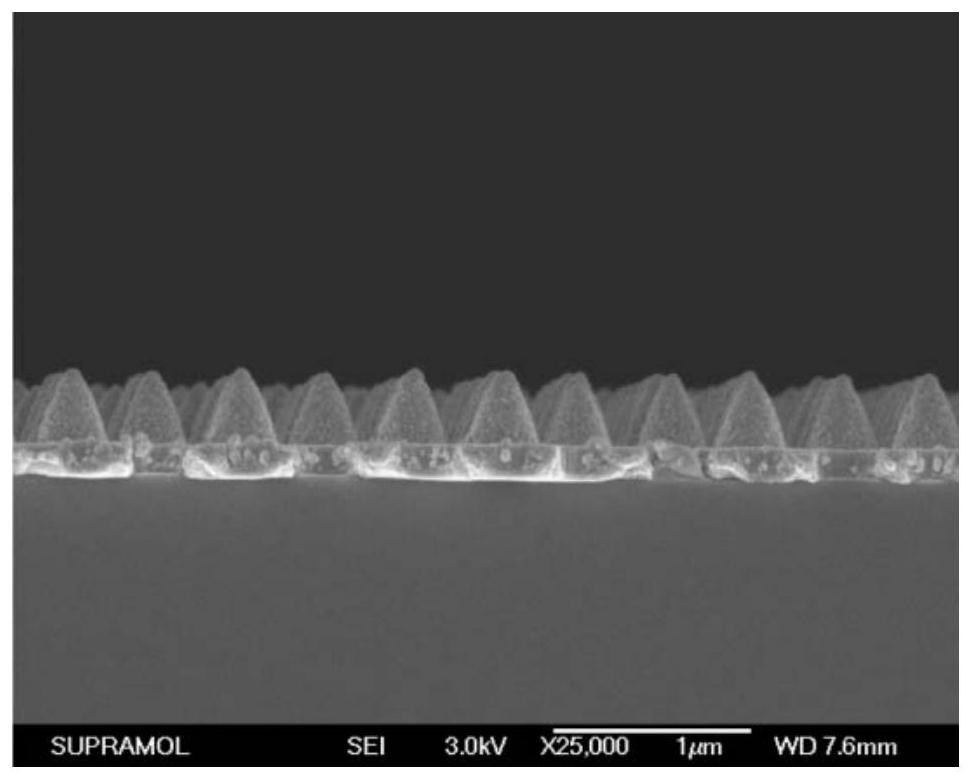

A kind of tapered array flexible electrode and preparation method thereof

ActiveCN109205551BShape and size controllableImprove structural stabilityDecorative surface effectsCoupling light guidesMicro nanoImplantable Electrodes

The invention provides a tapered array flexible electrode, which includes a flexible polymer substrate and a metal conductive layer, and one side surface of the flexible polymer substrate has a micro-nano tapered array structure, wherein the outer peripheral surface of the micro-nano tapered shape is rough surface; the metal conductive layer completely covers the outer peripheral surface of the micro-nano-cone, and completely covers the area on the side surface of the flexible polymer substrate where the micro-nano-cone is not provided. The flexible polymer substrate of the flexible electrode has good adhesion between the metal conductive layer, stable structure, low electrode impedance and excellent electrochemical performance. The flexible electrode can be well applied in flexible electronic skin and implantable electrodes. The invention also provides a preparation method of the tapered array flexible electrode.

Owner:SHENZHEN INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com