Glue rod material capable of improving low-temperature glueyness and preparation method thereof

A technology of low-temperature adhesives and adhesive modifiers, applied in the field of solid adhesives, which can solve the problems of restricting the application of solid adhesives, reduced adhesive performance, and hardening of glue sticks, so as to improve poor adhesiveness and adhesion. Fast speed, prevent dehydration and drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

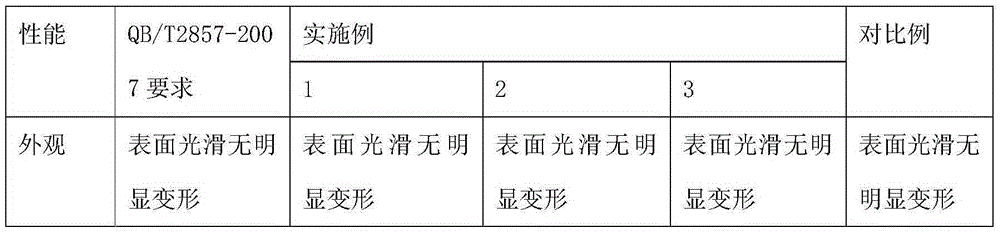

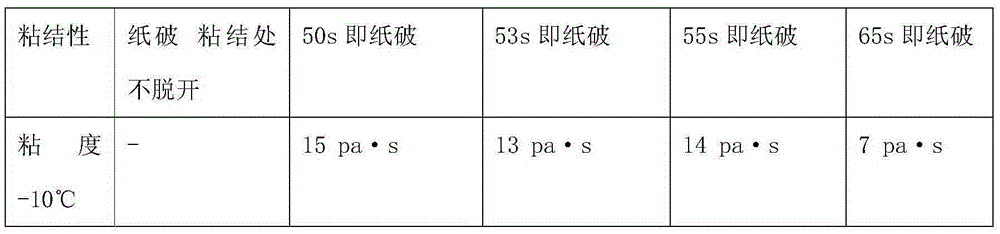

Examples

Embodiment 1

[0021] Embodiment 1: A kind of glue bar stock that improves low-temperature adhesiveness, its raw material is made up of adhesive base material, adhesive modifier, solidifying agent, humectant, other additives and water;

[0022] The mass parts of the raw materials are: 25 parts of adhesive base material, 15 parts of adhesive modifier, 12 parts of curing agent, 8 parts of moisturizing agent, 0.3 parts of other additives, and 39.7 parts of water;

[0023] The adhesive base material is anionic self-emulsifying water-based epoxy resin and sodium starch octenyl succinate, and its mass part ratio is 4:1, that is, 20 parts of anionic self-emulsifying water-based epoxy resin, octenyl succinate 5 parts of Sodium Starch Acid;

[0024] The adhesive modifier includes a water-based low-temperature modifier, N-methylolacrylamide and polyvinylpyrrolidone, and its mass percentage is: 1:1:3, that is, 3 parts of a water-based low-temperature modifier, N-hydroxyl 3 parts of methacrylamide, 9 p...

Embodiment 2

[0032] Embodiment 2: A kind of glue bar stock that improves low-temperature adhesiveness, it comprises the raw material of following mass parts: 20 parts of adhesive base material, 18 parts of adhesive modifier, 10 parts of solidifying agent, 10 parts of humectant , 0.5 parts of other additives, 41.5 parts of water;

[0033] The adhesive base material is anionic self-emulsifying water-based epoxy resin and sodium starch octenyl succinate, and its mass part ratio is 3:1; the adhesive modifier includes water-based low-temperature modifier, N -Methylolacrylamide and polyvinylpyrrolidone, the mass percentage is: 1:2:4.

[0034] Further, the water-based low-temperature modifier is thiourea, the solid agent is agar and sodium stearate, the humectant is a mixture of glycerin, polysorbate, and sodium lactate, and the other additives are antioxidant agents and preservatives.

Embodiment 3

[0035] Embodiment 3: A kind of glue bar stock that improves low-temperature adhesiveness, it comprises the raw material of following mass fraction: 30 parts of adhesive base material, 10 parts of adhesive modifier, 15 parts of solidifying agent, 5 parts of humectant , 0.2 parts of other additives, 39.8 parts of water;

[0036] The adhesive base material is anionic self-emulsifying water-based epoxy resin and sodium starch octenyl succinate, and its mass portion ratio is 5:1; the adhesive modifier includes water-based low-temperature modifier, N -Methylolacrylamide and polyvinylpyrrolidone, the mass percentage is: 1:1:2.

[0037] Further, the water-based low-temperature modifying agent is ethylene glycol, the solid agent is agar and sodium stearate, the humectant is a mixture of glycerin and sodium lactate, and the other auxiliary agents are antioxidants and antiseptic agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com