Patents

Literature

32results about How to "Overcome the disadvantage of poor adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

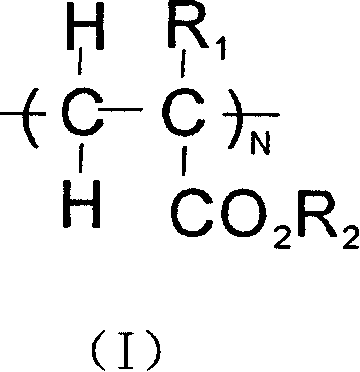

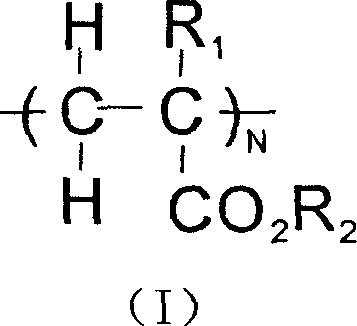

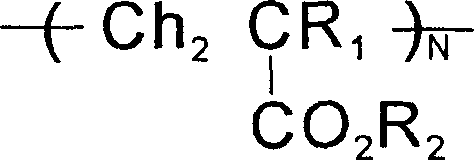

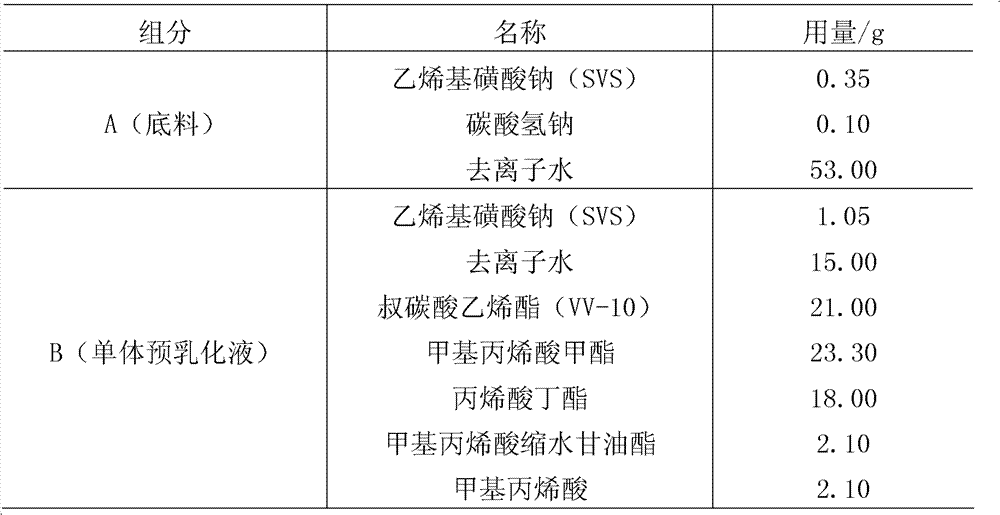

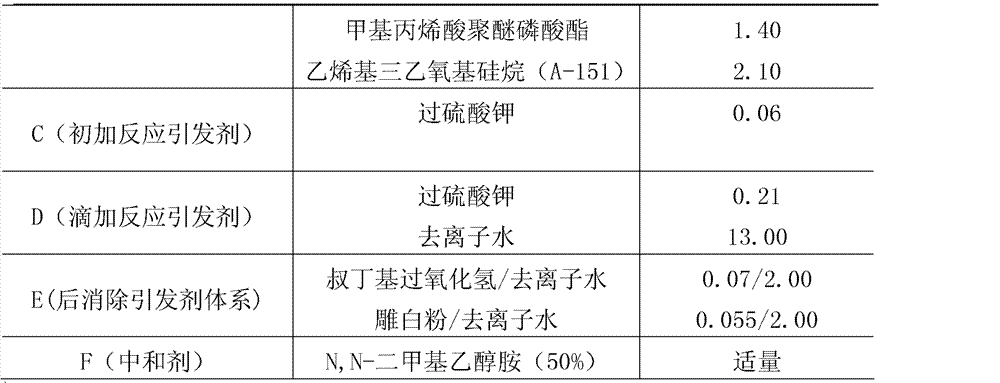

Preparation method for anti-rust soap-free acrylate emulsion

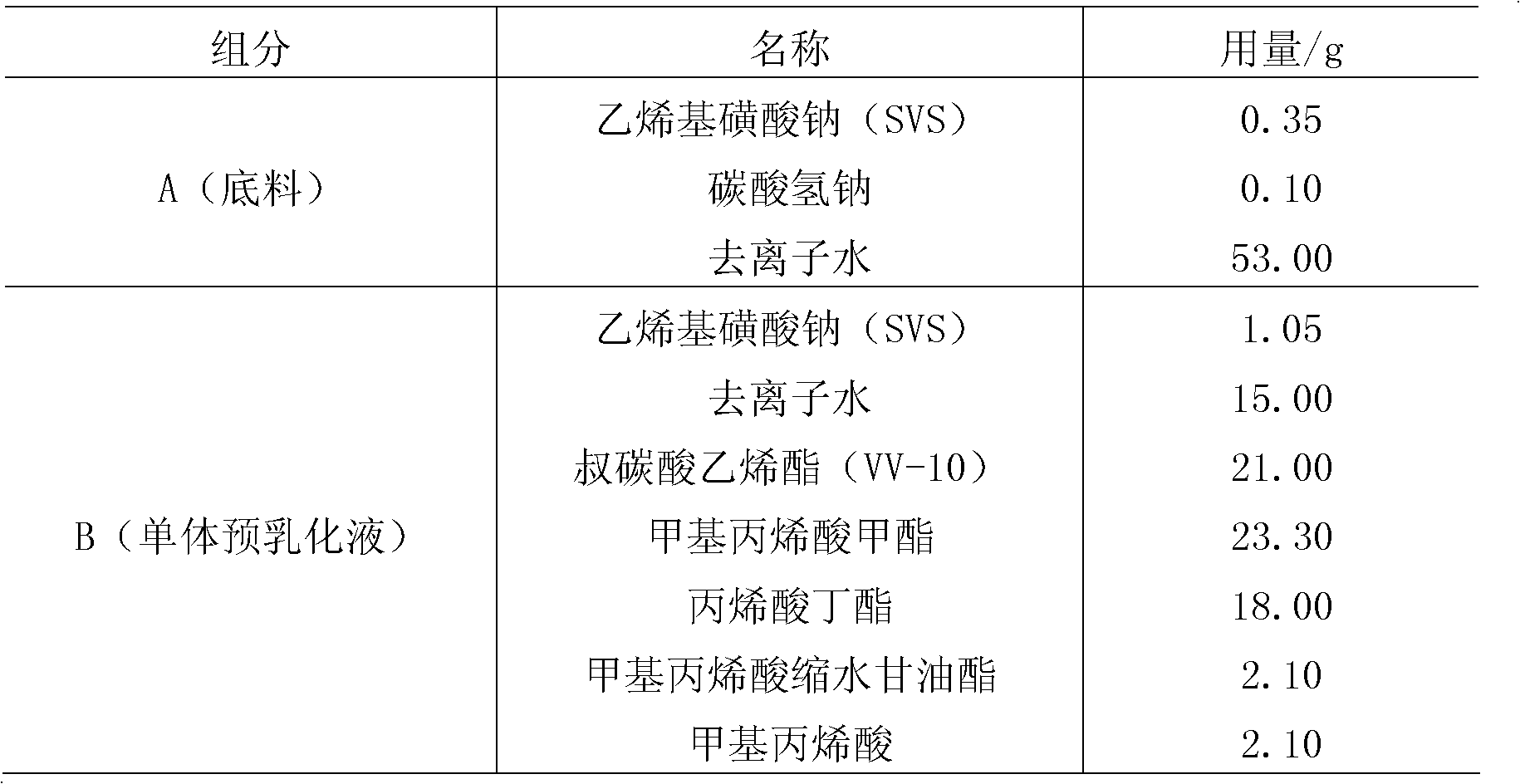

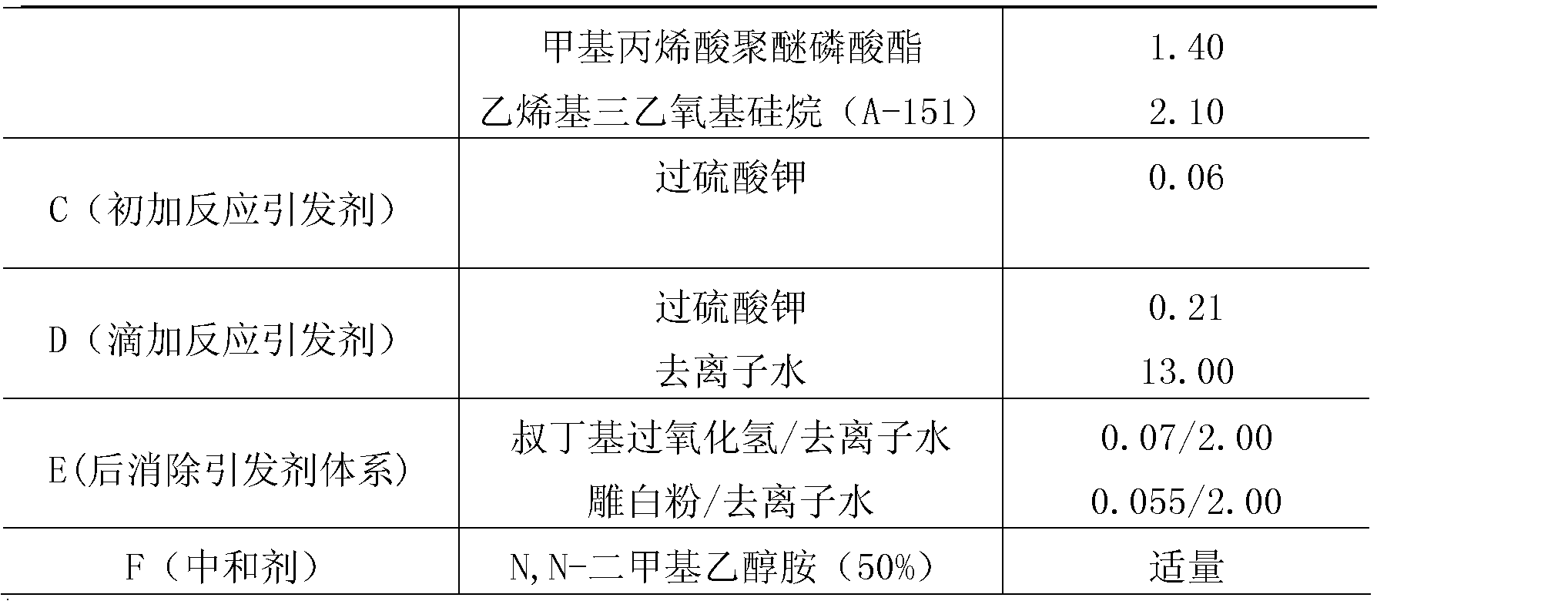

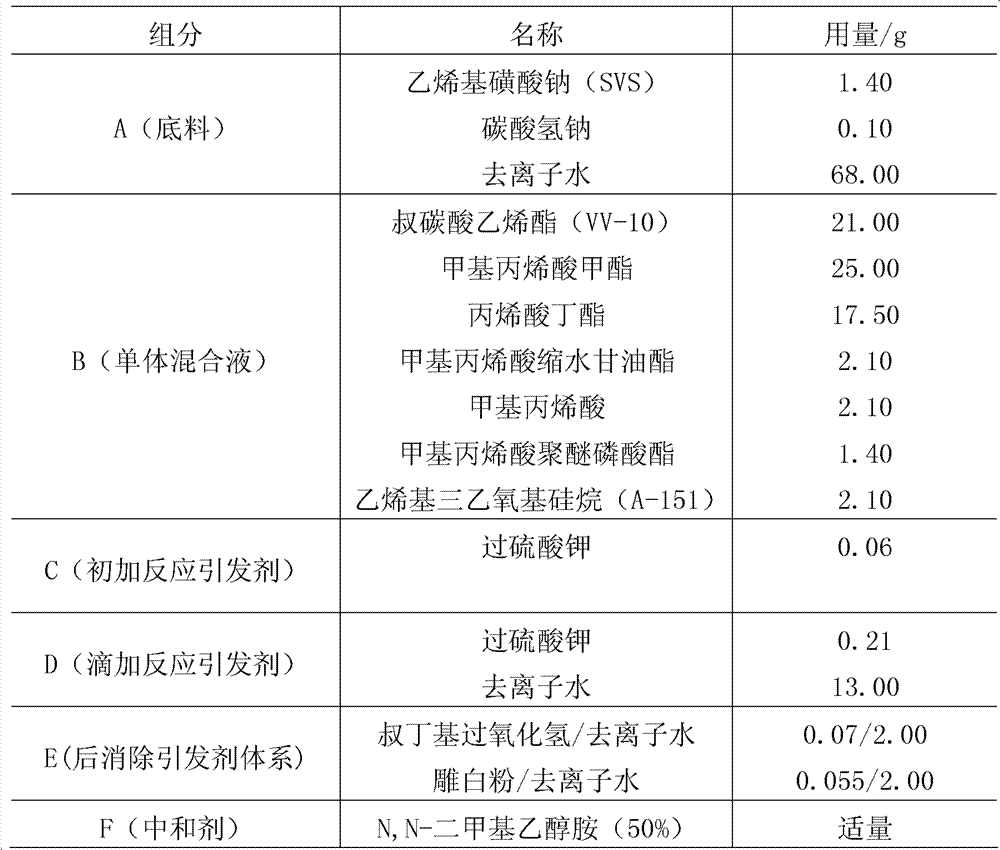

The invention relates to a preparation method for a base material of an anti-rust coating. The preparation method for an anti-rust soap-free acrylate emulsion is characterized in that a reactive emulsifier is selected, a polymeric monomer comprises (methyl) acrylic acid and an acrylic monomer thereof, a versatic acid vinyl monomer and a crosslinking monomer, a phosphate monomer is taken as a modified monomer, and the emulsion polymerization is carried out through semi-continue process under the action of an initiator, so that the soap-free anti-rust acrylate emulsion adopting water as dispersive medium is synthesized. The preparation method for the anti-rust soap-free acrylate emulsion can not only meet the requirement of environmental protection, but also enhance the rust resistance.

Owner:HUBEI EAST ST SPECIAL COATING TECH

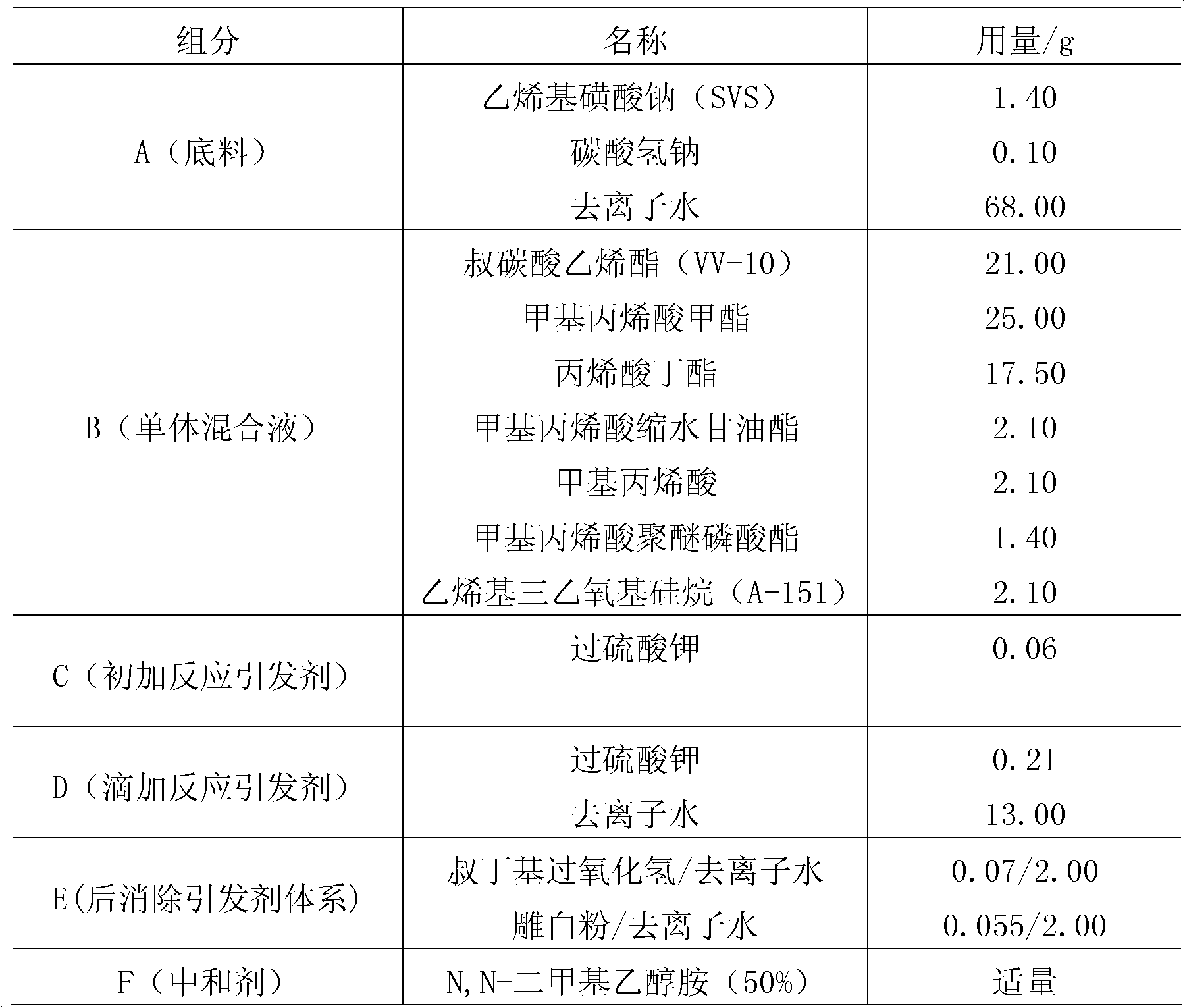

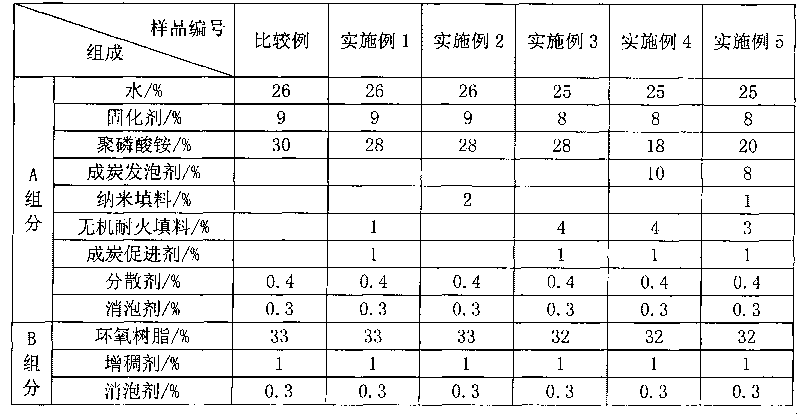

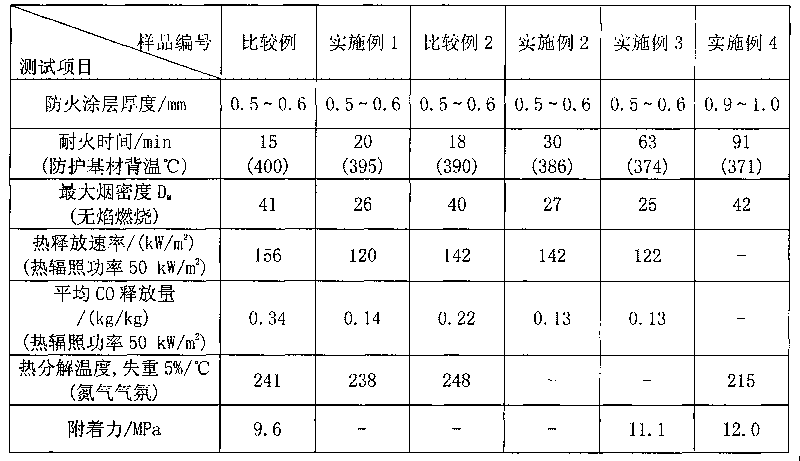

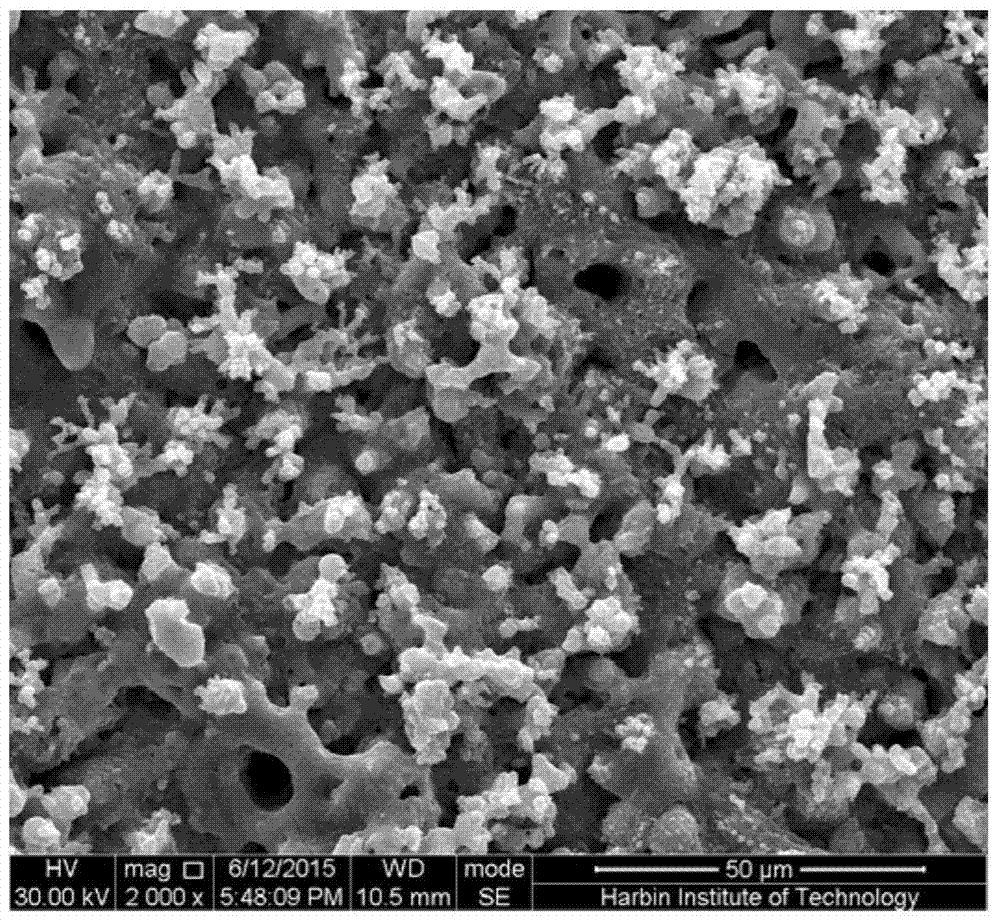

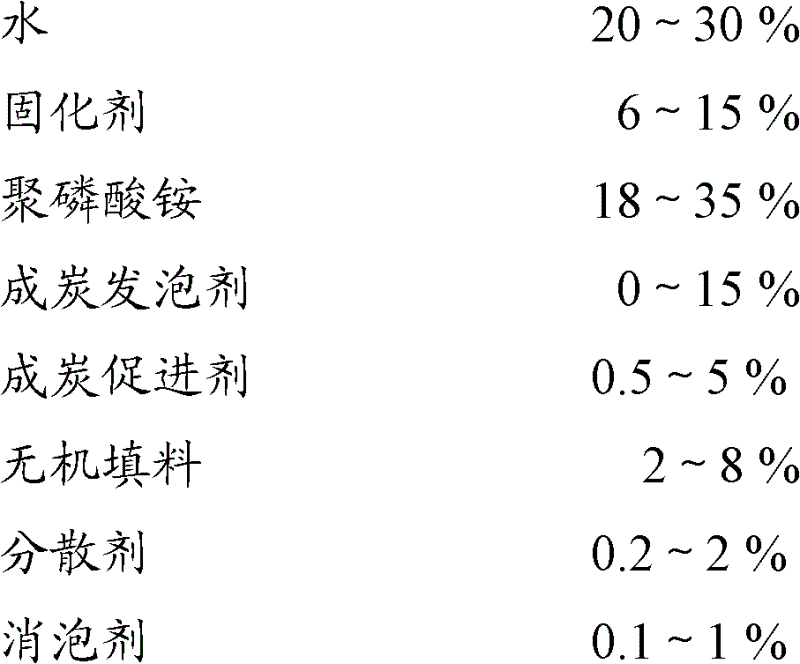

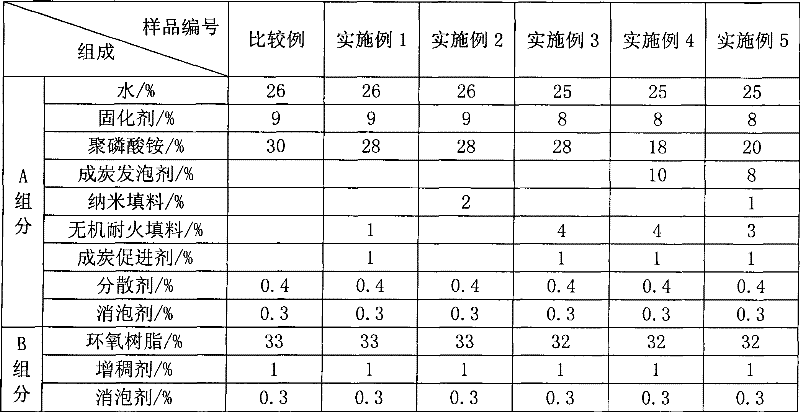

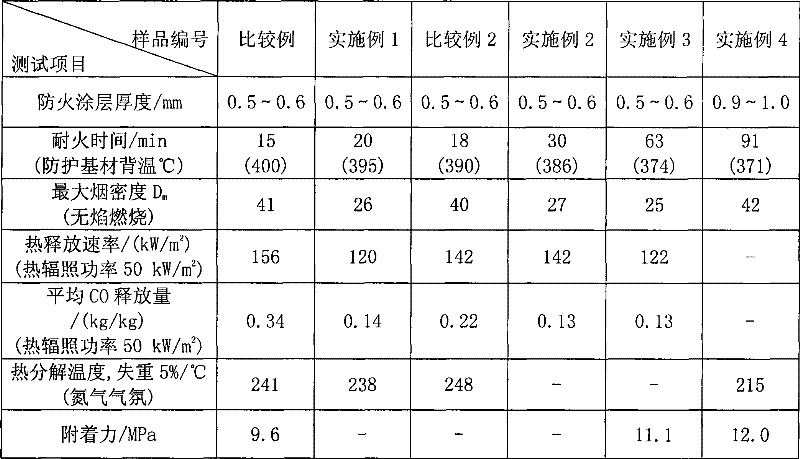

Ultrathin water-based epoxy resin expandable fireproof paint and preparation method thereof

InactiveCN101712840AEnvironmentally friendlyCorrosion resistantFireproof paintsEmulsion paintsWater basedEpoxy

The invention relates to an ultrathin water-based epoxy resin expandable fireproof paint and a preparation method thereof, belonging to the technical field of plating metal materials. The fireproof paint comprises water, aqueous epoxy emulsion, a solidification agent, ammonium polyphosphate, a charring foaming agent, a charring accelerant, nano fillers, inorganic fireproof fillers, a dispersing agent, a defoaming agent and a thickening agent. A ball milling machine is adopted for preparing a double-component paint; component A is prepared by two steps of: (1) dispersing the ammonium polyphosphate, the charring foaming agent, the charring accelerant, the nano fillers and the inorganic fireproof fillers in the water by the dispersing agent, with the milling time of 1 to 2 hours; and (2) adding the solidification agent and the defoaming agent for continuously milling for 0.5 to 1 hour; and component B is prepared by one step of: milling the aqueous epoxy emulsion, the thickening agent and the defoaming agent for 0.5 to 1 hour. When the coating thickness of the fireproof paint is smaller than or equal to 1mm, the fireproof time is larger than 90 minutes, the maximum smoke density is smaller than 50, and the adhesion force is larger than or equal to 12MPa. The invention has the advantages of simple preparation process, environmental protection and excellent performance, and can be used for the fire safety protection of the inner parts of large steel structures of buildings, ships, oil storage tanks and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

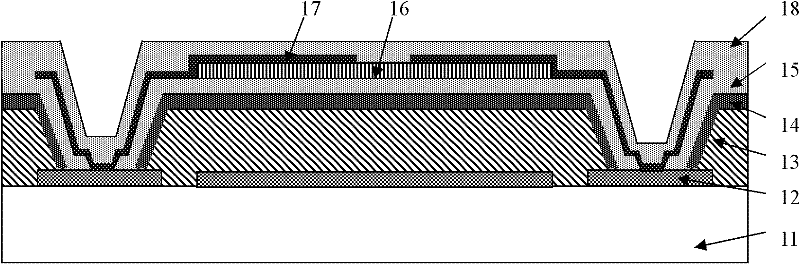

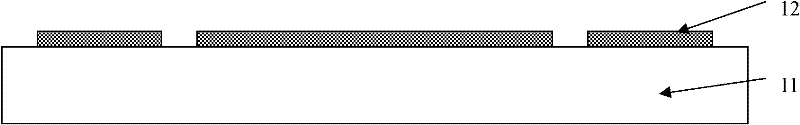

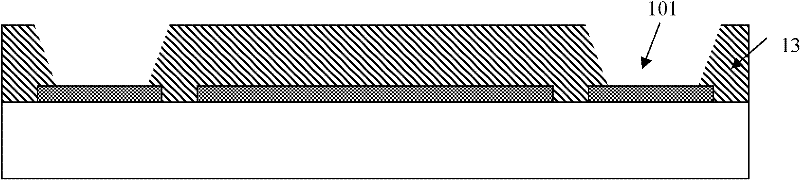

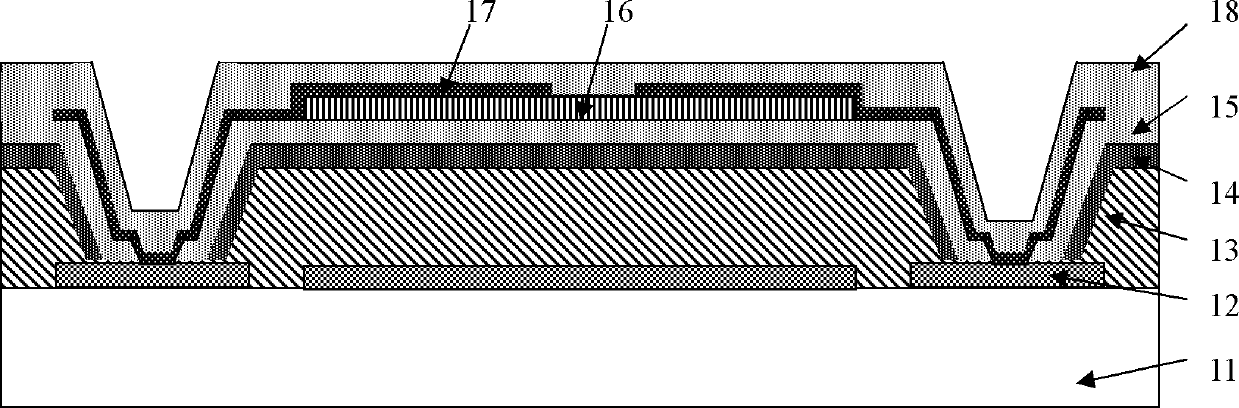

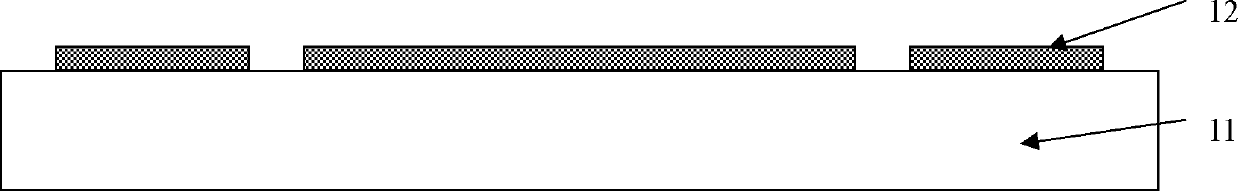

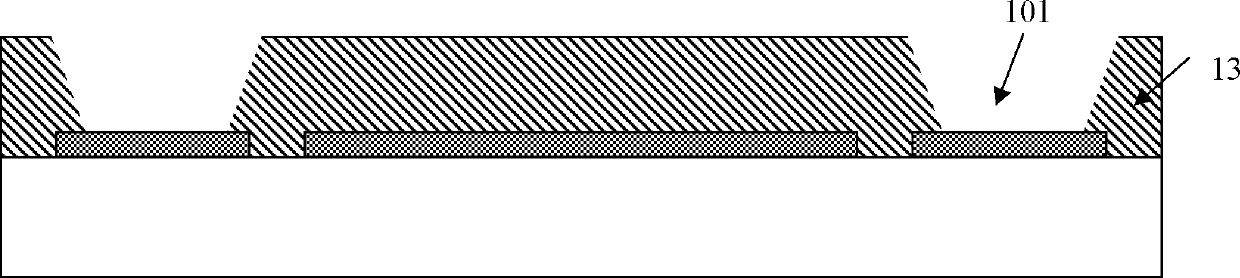

Infrared detector manufacturing method based on compound sacrificial layers

ActiveCN102683474APlay a role in flatteningOvercome the disadvantage of poor adhesionFinal product manufactureSemiconductor devicesAmorphous siliconMetal electrodes

The invention discloses a method utilizing compound sacrificial layers to manufacture an infrared detector. The method comprises sequentially enabling a metal layer, a first polyimide sacrificial layer, a second amorphous silicon sacrificial layer and through holes formed by imaging of the sacrificial layers to be arranged on a complementary metal-oxide-semiconductor (CMOS) silicon substrate; in a laminating mode, manufacturing a structure layer and contact holes formed by imaging; manufacturing a sensitive layer, a metal electrode layer and a release protecting layer, and imaging the sensitive layer, the electrode layer and a microbridge structure. When the sacrificial layers are released, first the second sacrificial layer is released, and then the first sacrificial layer is released. Compared with the prior art, the infrared detector manufacturing method effectively enables two kinds of different sacrificial layers to be effectively utilized, the organic sacrificial layer can be utilized to carry out planarization on the surface of a CMOS, the adhesion between the surface of the CMOS and metal is improved, and the inorganic sacrificial layer is utilized to control volatility of polyimide so as to be more compatible with the CMOS process.

Owner:ZHEJIANG DALI TECH

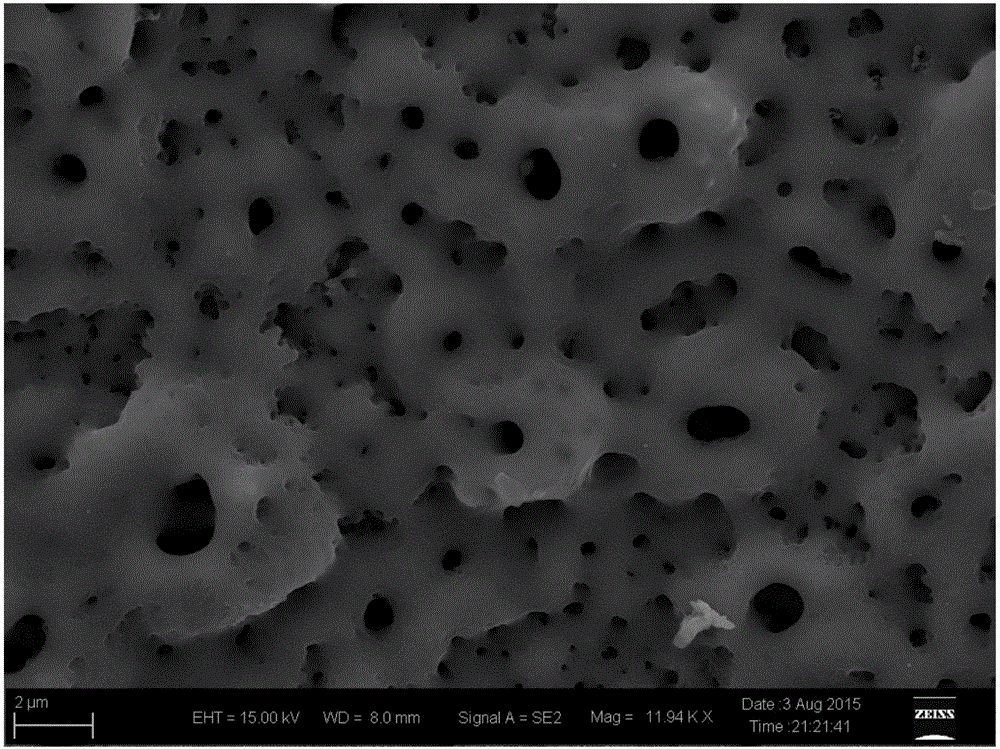

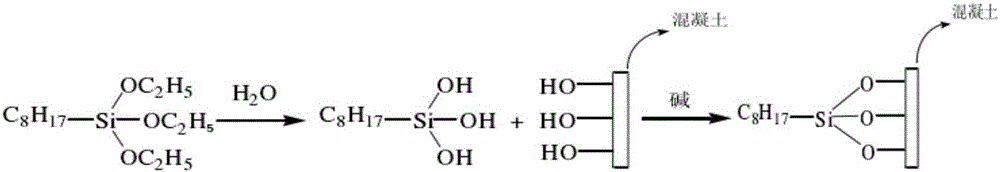

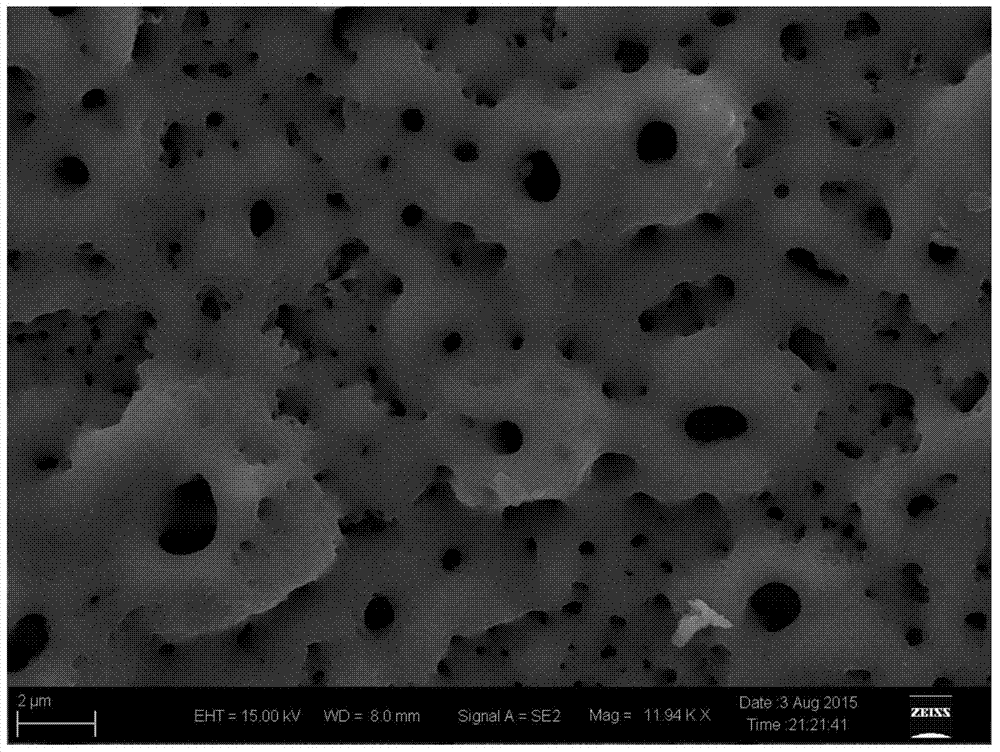

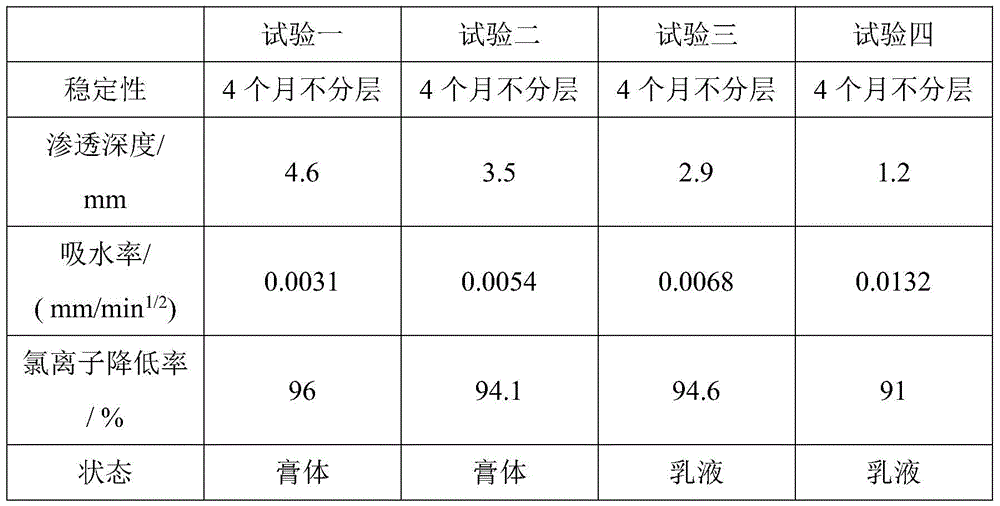

Preparation method for concrete silane paste impregnation waterproof agent

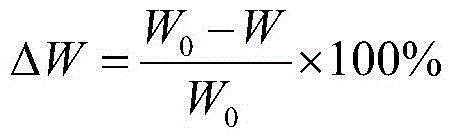

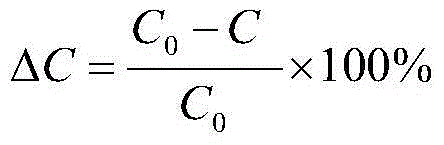

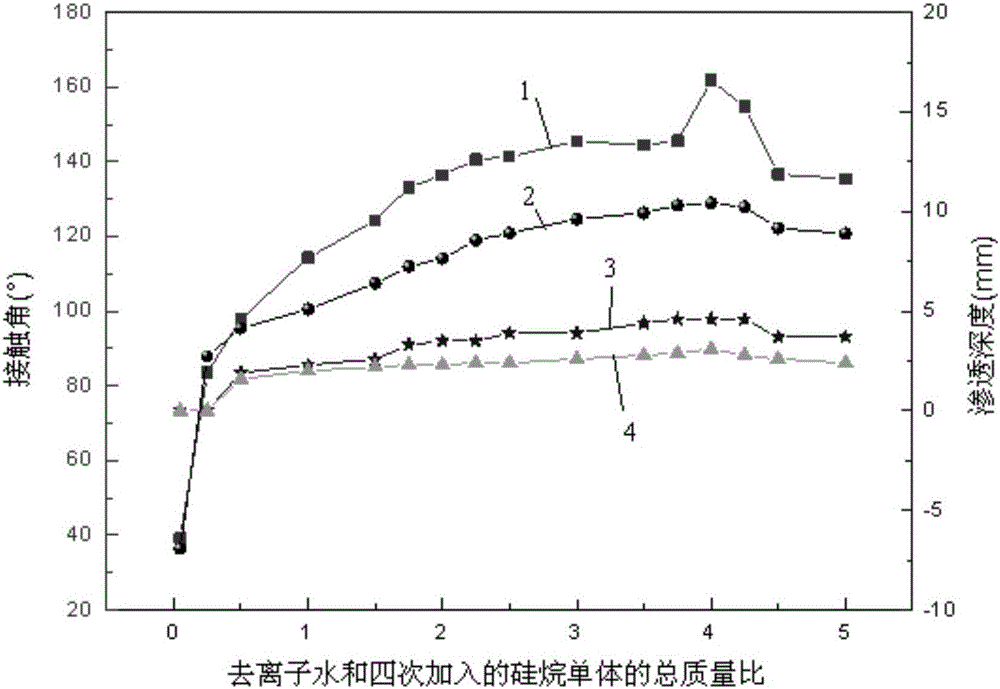

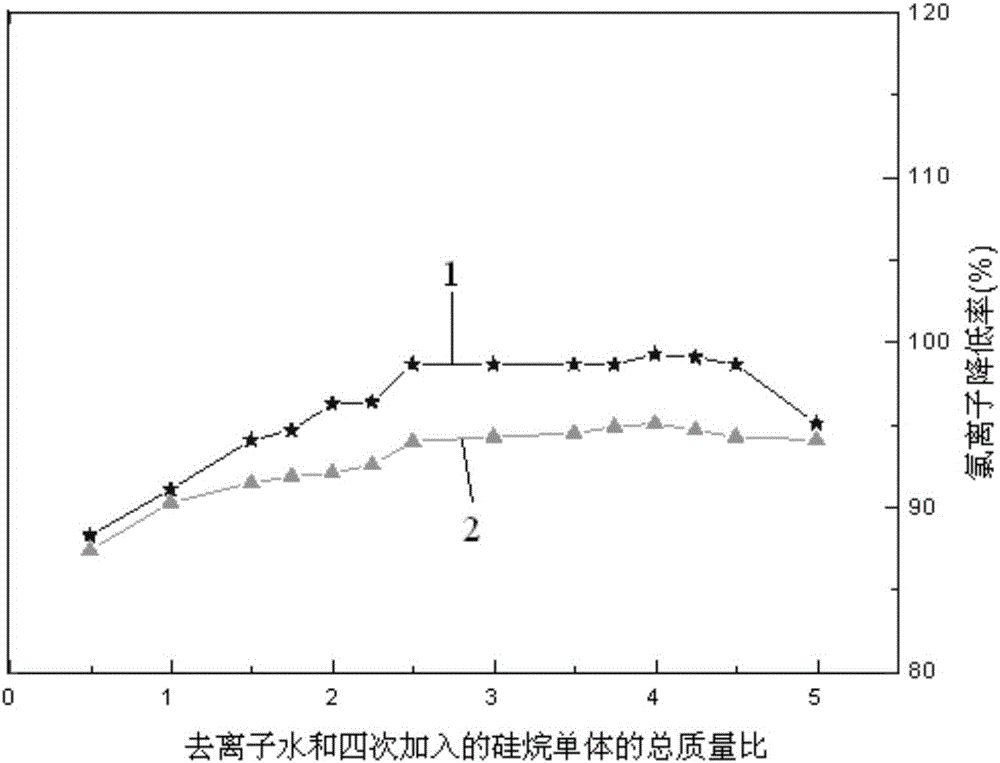

The invention provides a preparation method for a concrete silane paste impregnation waterproof agent, relates to a preparation method for an impregnation waterproof agent, and aims to solve the problems that the adhesion of existing liquid silane and silane emulsion is poor. The preparation method comprises the following steps: 1, weighing; 2, mixing to obtain a mixed solution; 3, performing initial reaction to obtain a reactant; 4, emulsifying to obtain the concrete silane paste impregnation waterproof agent. The preparation method has the advantages that the shortcoming of poor adhesion of liquid silane and silane emulsion is overcome, the construction is convenient, and multiple construction manners such as spraying, brushing and roll coating can be adopted for coating of vertical surfaces, so that the loss of active substances is reduced; the permeability of a pore structure of the material per se can be maintained; the waterproofness and permeability of the concrete silane paste impregnation waterproof agent are better than those of liquid silane and silane emulsion, the water absorption of a concrete structure can be reduced by 90% or above, the penetration depth of silane is increased, and silane can penetrate into the concrete surface at 3-4 mm. The method is mainly used for preparation of the concrete silane paste impregnation waterproof agent.

Owner:HARBIN INST OF TECH

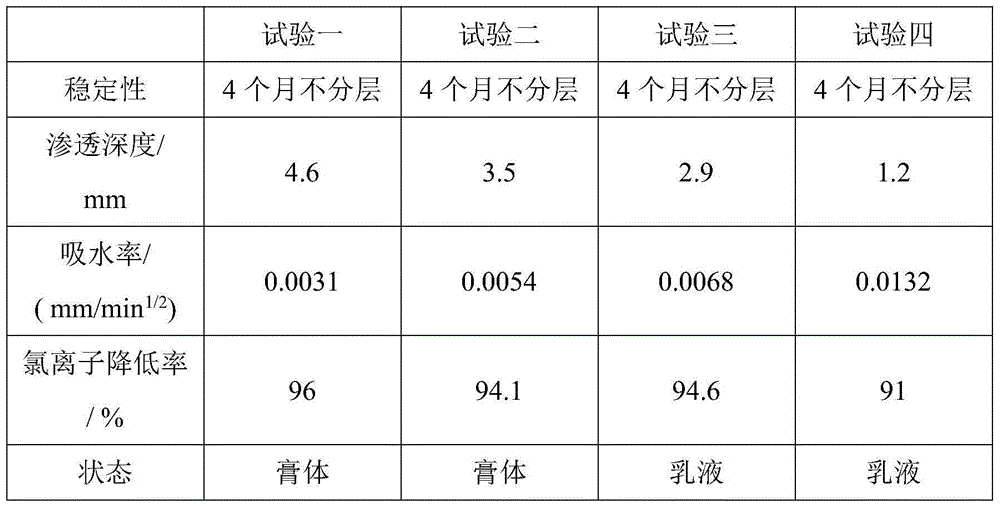

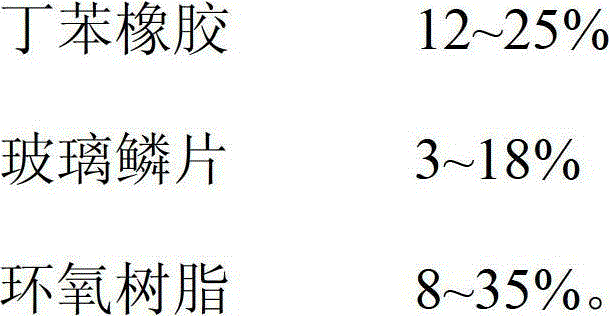

Pipeline coating, application thereof and pipeline coated with same

InactiveCN102719195AGood high temperature performanceImprove impact resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsButadiene-styrene rubberAsphalt

The invention relates to pipeline coating comprising an asphalt composition. The pipeline coating comprises, by weight, 30-80% of asphalt, 10-30% of butadiene styrene rubber, 1-20% of glass flakes and 5-40% of epoxy resin. The invention further provides a pipeline coated with the pipeline coating, a method using the pipeline coating to coat the pipeline and application of the pipeline coating comprising the asphalt composition. The pipeline coating is simple in manufacture method, has excellent impact resistance and flexibility and further displays excellent high-temperature property and adhesive force.

Owner:TIANCHANG JULONG TRAVEL PAINT

Plastic blending material, preparation method thereof and surface metalized plastic part

ActiveCN101684200ALow toxicityStrong adhesionLiquid/solution decomposition chemical coatingLaser beam welding apparatusPhotosensitizerMetal chelate

The invention provides an inorganic filler plastic blending material, a preparation method thereof and a surface metalized plastic part which takes the blending material as raw material and is manufactured according to a laser direct forming process, wherein, at least one kind of transition metal ions and nanoscale metal particles is coated on the surface of the inorganic filler plastic blending material. The inorganic filler plastic blending material overcomes the disadvantages that the organic metal chelate used as photosensitizer additive has high plastic toxity and high cost, and the processing technique is complex; in addition, the adhesive force of the coated metal of the surface metalized plastic piece prepared by the plastic blending material and the basal body of the plastic pieceis good.

Owner:BYD CO LTD

Method for preparing nano composite material from waste material and CO2

InactiveCN101077920AReduce energy consumptionOvercome the disadvantage of poor adhesionProduction lineOligomer

The present invention provides process of producing high performance nanometer composite material with waste and CO2 as main material and medium. The high performance nanometer composite material is produced with organosilicon compound, aliphatic acrylic acid and its ester derivative and / or oligomer as monomer material, CO2 as medium, inorganic waste and organic waste, and through diffusion, mixing, reaction, etc. The high performance nanometer composite material may be used widely in different fields, and the used product may be recovered for reuse.

Owner:龚克成 +1

Preparation method for titanium alloy TA2 surface high-solar absorptivity low-emissivity film layer

ActiveCN105040070ASimple processLow costSurface reaction electrolytic coatingMicro arc oxidationLow emissivity

The invention relates to a preparation method for a titanium alloy TA2 surface ceramic film layer, in particular to a preparation method for a titanium alloy TA2 surface high-solar absorptivity low-emissivity film layer, and aims to solve the problems that an existing titanium alloy TA2 surface coating is low in solar absorptivity, high in self emissivity, and low in bonding force of a film layer and a base body. The preparation method comprises the steps that 1, pretreatment is carried out on titanium alloy TA2; 2, micro-arc oxidation is carried out to obtain a titanium alloy TA2 surface high-solar absorptivity low-emissivity film layer. The thickness of the prepared titanium alloy TA2 surface high-solar absorptivity low-emissivity film layer ranges from 0.3 micron to 1 micron, the roughness of the film layer ranges from 0.2 micron to 0.25 micron, solar absorptivity ranges from 0.82 to 0.9, and emissivity ranges from 0.08 to 0.13. The titanium alloy TA2 surface high-solar absorptivity low-emissivity film layer can be obtained through the preparation method.

Owner:HARBIN INST OF TECH

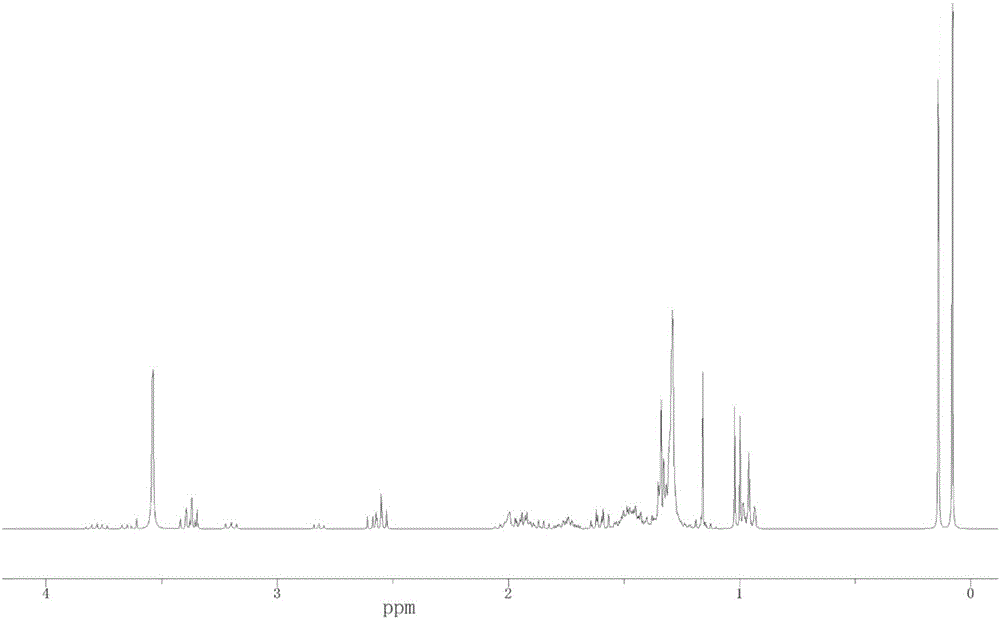

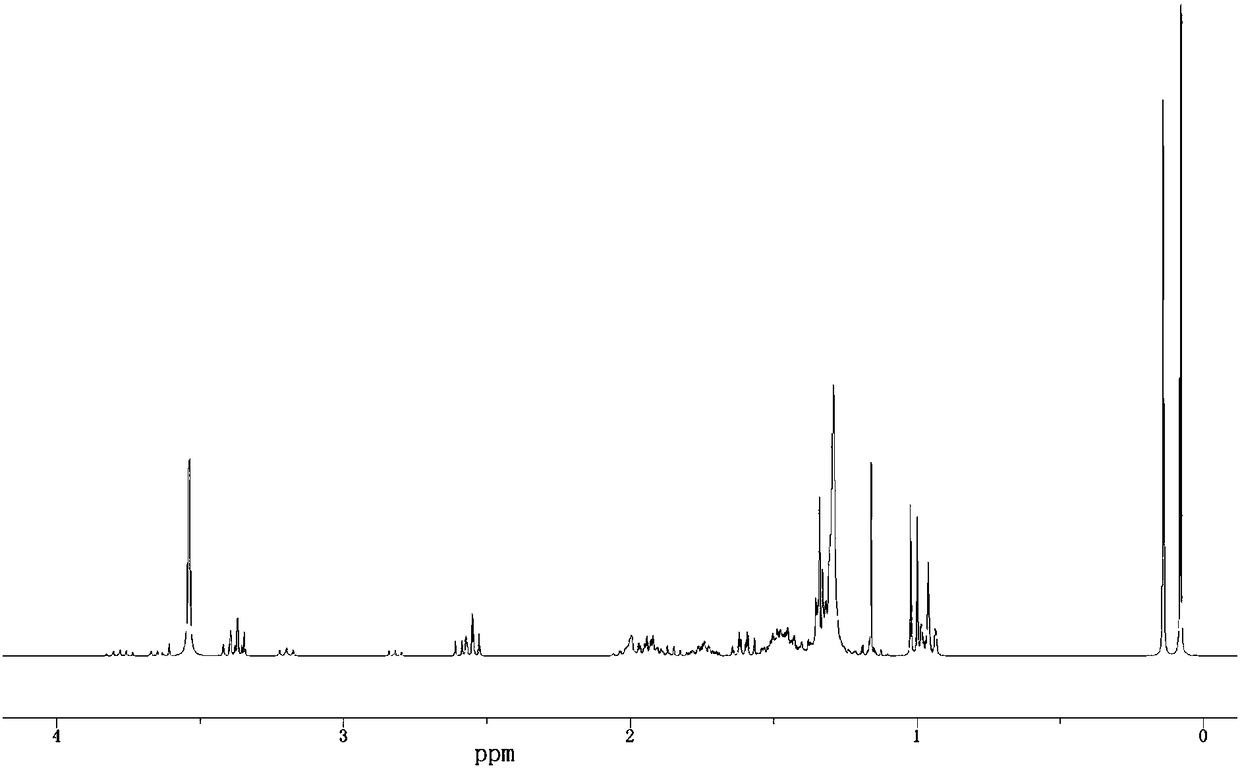

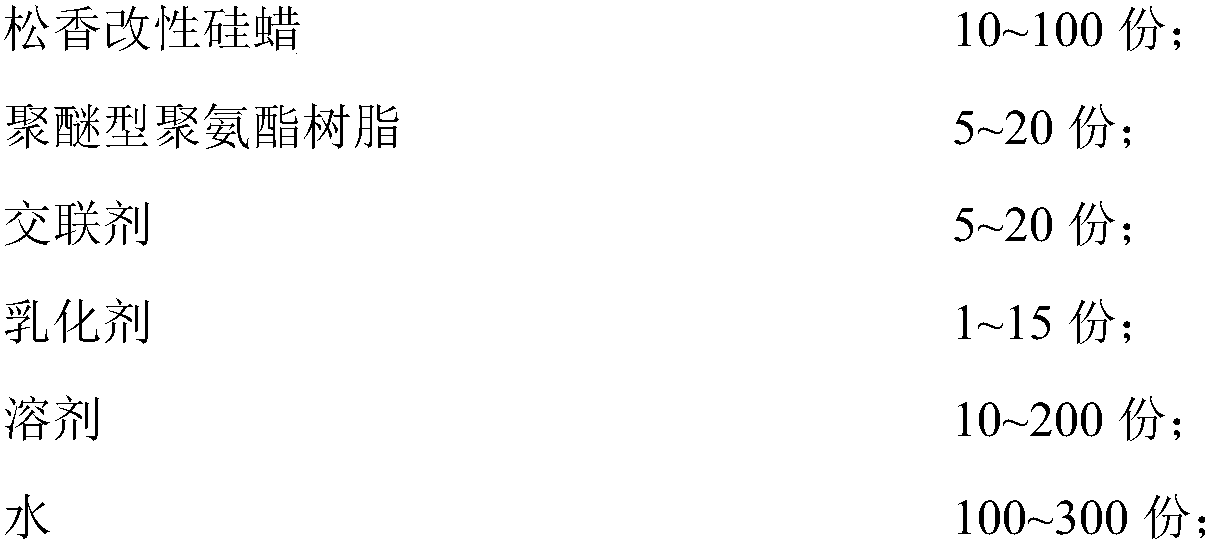

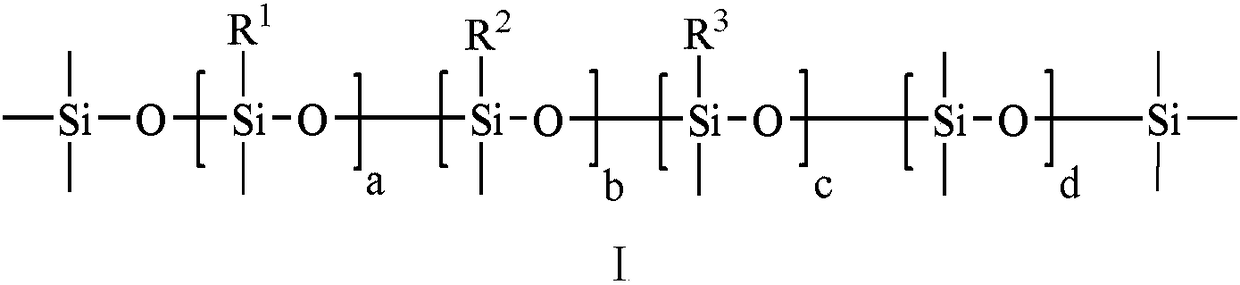

Environment-friendly rosinyl fluoride-free waterproof agent and preparation method thereof

ActiveCN106120349AIncrease profitReduce dependenceLiquid repellent fibresEnvironmental resistanceSiphon

The invention relates to a rosinyl fluoride-free waterproof agent and a preparation method thereof. The rosinyl fluoride-free waterproof agent is prepared from the following raw materials in parts by weight: 10-100 parts of rosin-modified silicon wax, 5-20 parts of polyether urethane resins, 5-20 parts of cross-linking agents, 1-15 parts of emulsifying agents, 10-200 parts of solvents and 100-300 parts of water. The rosinyl fluoride-free waterproof agent provided by the invention is arranged as an environment-friendly waterproof agent; the waterproof agent is free from fluorocarbon compound; the defect of poor dynamic siphon-proof property of the fluoride-free waterproof agent in the prior art is overcome; the rosinyl fluoride-free waterproof agent has excellent static siphon-proof property; the defect of poor adhesive force of the waterproof agent product and superfine fiber synthetic leather base cloth in the prior art is overcome; the green reproducible natural rosin or ramification thereof is taken as the raw material, so that the waterproof agent has an important value of environmental protection and ultra-wide application prospect; the preparation is simple and environment-friendly.

Owner:太仓中化环保化工有限公司

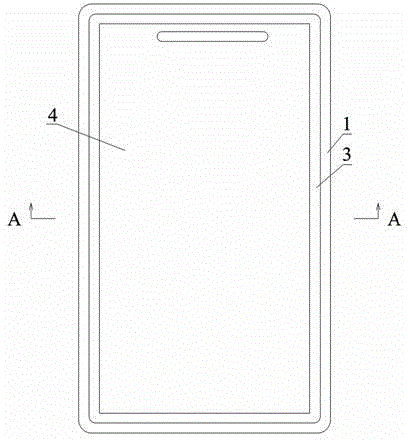

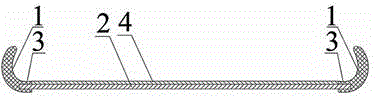

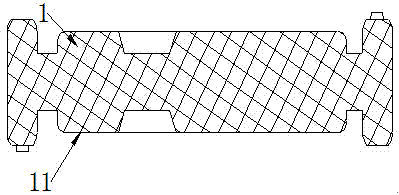

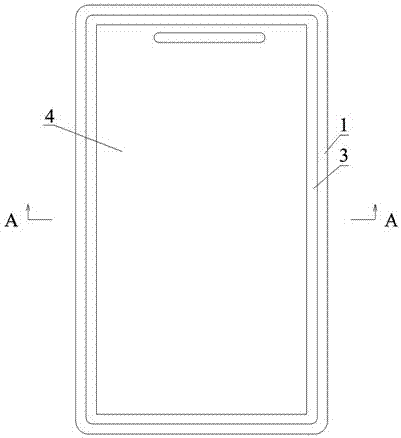

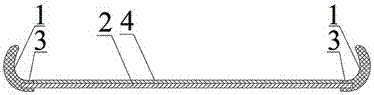

Digital electronic equipment protective film and machining process thereof

InactiveCN104960763AImprove wear resistanceImprove buffering effectFlexible coversWrappersTectorial membraneDie casting

The invention discloses a digital electronic equipment protective film. The digital electronic equipment protective film comprises a plastic frame (1) integrally molded through injection molding, and a rectangular basal plate (2), wherein the bottom of the plastic frame (1) has an annular connecting edge (3) for mounting the basal plate (2); the annular connecting edge (3) tightly coats the edge of the basal plate (2); and the edge of the basal plate (2) is embedded in the annular connecting edge (3). The invention further discloses a machining process of the digital electronic equipment protective film. The digital electronic equipment protective film and the machining process thereof have the following beneficial effects: the digital electronic equipment protective film synthesizes the advantages of glass materials and silica gel materials (including silica gel and such plastics as pet, abs, pp and pc), so that excellent protection effect can be achieved, the thickness of the protective film can be decreased, and the transparency is excellent; and the machining method adopting the high-precision mold injection molding or the die casting of the frame at the periphery of the glass basal plate guarantees excellent connecting structure between the glass basal plate and the plastic frame, and overcomes the defect of weak binding force between the glass materials and the silica gel materials.

Owner:李灵敏

Polyisoprene gasket synthesized by medicinal film

InactiveCN104744744AOvercome the disadvantage of poor adhesionOmit inner coverMedical productFilm material

The invention discloses a polyisoprene gasket synthesized by a medicinal film and belongs to the technical field of medical product. The formulae of the polyisoprene gasket in parts by weight are as follows: 100 parts of polyisoprene rubber, 15-20 parts of kaolin, 5-10 parts of white carbon black, 5 parts of zinc oxide, 0.3 parts of carbon black, 4 parts of titanium dioxide and 1.2 parts of vulcanizing agent; the production process flow comprises the following steps: (1) preparing the materials; (2) refining rubber; (3) performing; (4) one-time vulcanizing; (5) one-time deflashing; (6) second-time vulcanizing; (7) second-time deflashing; and (8) washing. The polyisoprene gasket synthesized by the medicinal film has the following advantages: the defect of the bad adhesiveness of the traditional polyisoprene gasket and the film material is overcome, the rubber gasket product is directly contacted with the medical liquid so that the inner cap of a composite cover is omitted and the related requirement of directly contacting the transfusion medicine is met; due to a special structure design, the resistance of the puncture process is reduced in the using process, the generation of the puncture scraps is reduced and the polyisoprene gasket is convenient for the hospital use.

Owner:ANHUI HUAFENG PHARMA RUBBER

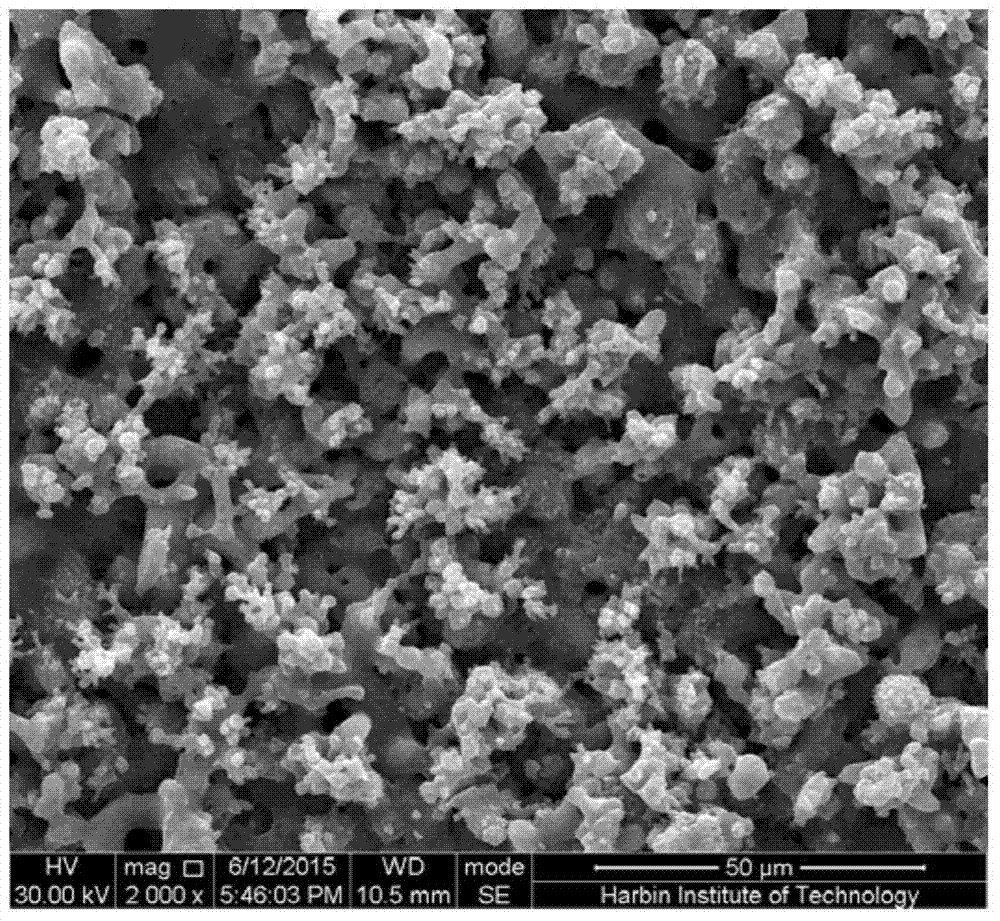

Production method of high-dispersion high-thermal-stability insoluble sulfur

InactiveCN103318848AOvercome the disadvantage of poor adhesionUniform component performanceSulfur preparation/purificationSulfurThermal stability

The invention discloses a production method of high-dispersion high-thermal-stability insoluble sulfur. The method comprises the following steps: sulfur melting and heating: melting common sulfur at 145-155DEG C for sulfur melting, pumping the obtained melt to a heating tank, heating to 250-280DEG C, adding diethylhydroxylamine having a weight being 0.5-1% of the weight of sulfur, uniformly stirring, and heating to 490-550DEG C; and atomizing, quenching, curing, and cladding. The production method greatly improves the high-thermal-stability and the dispersibility of insoluble sulfur, and the insoluble sulfur obtained in the invention can completely satisfy the requirements of three-high insoluble sulfur by radial tires.

Owner:SHANGHAI JINGHAI ANHUI CHEM

Preparation method for concrete silane paste waterproofing agent

The invention provides a preparation method for a concrete silane paste waterproofing agent, and relates to the preparation method for a concrete silane waterproofing agent. The invention aims to solve the technical problems of coating failure due to capability of breaking surface coating during discharging of internal water of a protective coating on the surface of concrete, and incapability of guaranteeing self permeability of a concrete material in the prior art. The preparation method provided by the invention comprises the following steps: subjecting deionized water and a compound emulsifier to stirring until the compound emulsifier is completely dissolved, then adding amino silicon oil and triethylamine, adding a silane monomer, then carrying out stirring, carrying out natural cooling to room temperature, adding phosphoric acid until the mixture is neutral, adding a stabilizing agent and a sterilizing agent, and carrying out emulsification with a high-speed emulsifying machine. The preparation method provided by the invention uses water as a solvent, does not use a volatile solvent, and is free of harm to the environment and human; and compared with a pure silane monomer, the waterproofing agent has the advantages of little volatilization, high utilization rate, large penetration depth, simple process and good waterproof effect. The waterproofing agent provided by the invention has good stability, and has uniform color, no purity, no stratification, no floating oil and no obvious precipitate after standing for 4 months.

Owner:无锡鸿孚硅业科技有限公司

Bisphenol A epoxy resin modified bifunctional polyester acrylate UV (ultraviolet)-transparent primer for wooden furniture and preparation method thereof

ActiveCN104152017AOvercome the disadvantage of poor adhesionGood flexibilityPolyester coatingsPolyesterDrying time

The invention provides a bisphenol A epoxy resin modified bifunctional polyester acrylate UV (ultraviolet)-transparent primer for wooden furniture, which comprises the following components in percentage by weight: 30-55% of bifunctional polyester acrylate, 0.1-0.3% of wetting and dispersing agent, 0.3-0.5% of defoaming agent, 18-40% of filler, 8-20% of monomer, 0.3-0.6% of leveling agent, 1-3% of bisphenol A epoxy resin and 3-10% of initiator. The primer has the advantages of favorable color, favorable transparency, favorable glossiness, low cost, stable properties and high storability; and the primer film has the advantages of short drying time, favorable transparency, high glossiness, favorable fullness and excellent mechanical properties. The invention also provides a preparation method of the transparent primer. The method has the advantages of simple technique, simple operation, favorable repetitiveness, short production cycle and high production efficiency, and is very suitable for industrialized production.

Owner:FOSHAN GAOMING FULONGSI NEW MATERIAL TECH

Preparation method for anti-rust soap-free acrylate emulsion

The invention relates to a preparation method for a base material of an anti-rust coating. The preparation method for an anti-rust soap-free acrylate emulsion is characterized in that a reactive emulsifier is selected, a polymeric monomer comprises (methyl) acrylic acid and an acrylic monomer thereof, a versatic acid vinyl monomer and a crosslinking monomer, a phosphate monomer is taken as a modified monomer, and the emulsion polymerization is carried out through semi-continue process under the action of an initiator, so that the soap-free anti-rust acrylate emulsion adopting water as dispersive medium is synthesized. The preparation method for the anti-rust soap-free acrylate emulsion can not only meet the requirement of environmental protection, but also enhance the rust resistance.

Owner:HUBEI EAST ST SPECIAL COATING TECH

Anti-stripping sulfur asphalt as well as preparation method and application thereof

PendingCN114479489ASense of smellTo achieve a sustained release effectBuilding insulationsParticulatesPhenol

The invention discloses anti-stripping sulfur asphalt as well as a preparation method and application thereof. The anti-stripping sulfur asphalt is prepared from the following raw materials: 5 to 20 parts of sulfur, 1 to 5 parts of naphthalene series, 2 to 8 parts of ethylene-vinyl acetate copolymer, 1 to 3 parts of styrenated phenol, 1 to 3 parts of nitrogen-containing aromatic compound and 60 to 90 parts of petroleum asphalt. The preparation method of the anti-stripping sulfur asphalt comprises the following steps: (1) carrying out a reaction on sulfur and a naphthalene-based substance in an inert atmosphere, and (2) mixing and granulating an ethylene-vinyl acetate copolymer, styrenated phenol, a nitrogen-containing aromatic compound and a reaction product obtained in the step (1) to obtain particles, and (3) heating and melting the petroleum asphalt, and then adding the particulate matters to obtain the anti-stripping sulfur asphalt. The anti-stripping sulfur asphalt is particularly suitable for paving airport runways. The anti-stripping sulfur asphalt disclosed by the invention not only has relatively strong anti-stripping capability and very strong adaptability to a high-temperature wake flow environment of an airplane, but also has an ecological bird repelling function.

Owner:CHINA PETROLEUM & CHEM CORP +1

Infrared detector manufacturing method based on compound sacrificial layers

ActiveCN102683474BPlay a role in flatteningOvercome the disadvantage of poor adhesionFinal product manufactureSemiconductor devicesAmorphous siliconMetal electrodes

The invention discloses a method utilizing compound sacrificial layers to manufacture an infrared detector. The method comprises sequentially enabling a metal layer, a first polyimide sacrificial layer, a second amorphous silicon sacrificial layer and through holes formed by imaging of the sacrificial layers to be arranged on a complementary metal-oxide-semiconductor (CMOS) silicon substrate; in a laminating mode, manufacturing a structure layer and contact holes formed by imaging; manufacturing a sensitive layer, a metal electrode layer and a release protecting layer, and imaging the sensitive layer, the electrode layer and a microbridge structure. When the sacrificial layers are released, first the second sacrificial layer is released, and then the first sacrificial layer is released. Compared with the prior art, the infrared detector manufacturing method effectively enables two kinds of different sacrificial layers to be effectively utilized, the organic sacrificial layer can be utilized to carry out planarization on the surface of a CMOS, the adhesion between the surface of the CMOS and metal is improved, and the inorganic sacrificial layer is utilized to control volatility of polyimide so as to be more compatible with the CMOS process.

Owner:ZHEJIANG DALI TECH

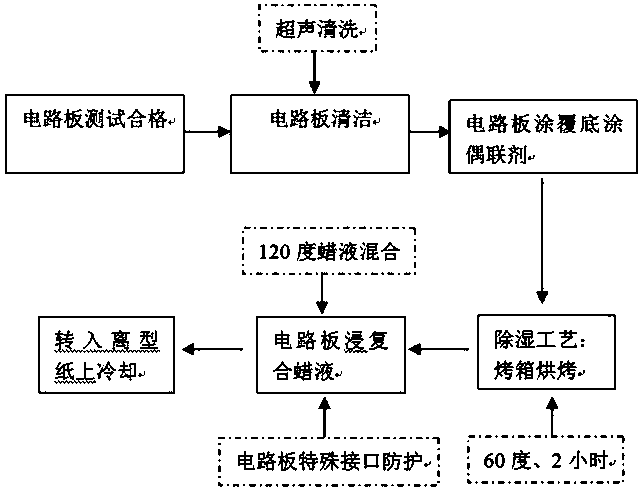

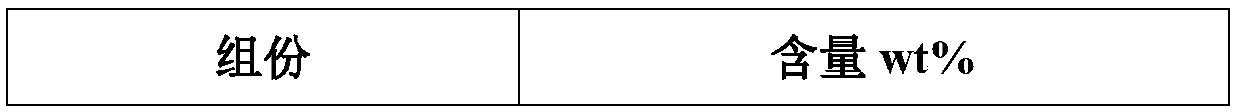

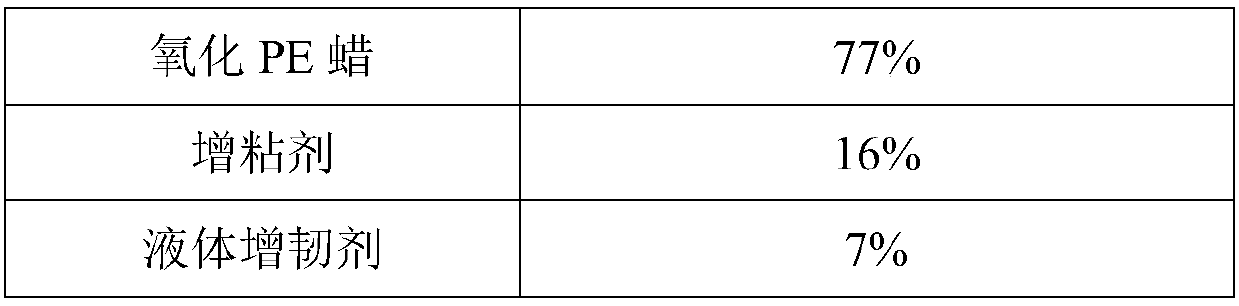

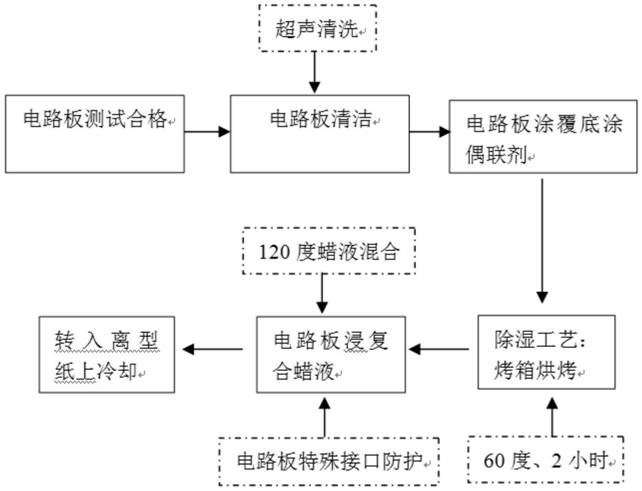

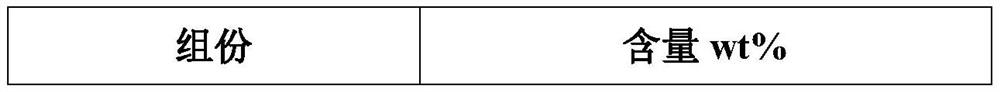

Method for applying oxidized PE wax to sealing protection of circuit board

ActiveCN109628018AOvercome the disadvantage of easy cracking at low temperatureOvercome the disadvantage of poor adhesionPrinted circuit detailsMacromolecular adhesive additivesWaxAdhesion force

The invention relates to a method for applying oxidized PE wax to sealing protection of a circuit board. The method comprises the steps that the surface of the circuit board is coated with a layer ofcoupling agent, and air drying is conducted; the circuit board is dehumidified; a tackifier and a liquid toughening agent are added into the molten oxidized polyethylene wax to be uniformly mixed to prepare molten wax; the dehumidified circuit board is immersed in the molten wax for sealing, and after sealing is completed, the circuit board is placed on release paper and dried. By means of the sealing method, the defects that the oxidized PE wax easily cracks at the low temperature and has poor adhesion force are overcome; the tackifier and the toughening agent is added according to a ratio through repeated experiments, and finally, the oxidized PE wax can meet the requirement of the circuit board for effective waterproof and moisture-proof sealing in the working environment at minus 20-60DEG C. By means of the method, the good acid and alkali resistance, electrolytic-resistance chemical stability and hydrophobicity of the main ingredient PE wax are fully utilized, and a layer of waxfilm is formed on the surface of the circuit board and a component to protect the circuit board after melting.

Owner:康威通信技术股份有限公司

Method for curing and grafting amphoteric ion gel coat on external surface on material surface by ultraviolet

InactiveCN102775831BOvercome the disadvantage of poor adhesionImprove adhesionAntifouling/underwater paintsPaints with biocidesChemical reactionSilanes

The invention discloses a method for curing and grafting amphoteric ion gel coat on external surface on material surface by ultraviolet. According to the method, a layer of visible-light curable organic / inorganic hybrid translation layer including chemically reactive unsaturated duplet bond and photo-initiator is coated on the surface of a substrate to be modified, then a layer of visible-light curable gel solution including amphoteric ion monomer, polyenoid cross linking agent and photo-initiator is coated on the surface of the translation layer, and irradiation is carried out under ultraviolet, so as to obtain the gel coat having amphoteric ions. The visible-light curable organic / inorganic hybrid translation layer is prepared by adding a silane precursor, solvent and water in a reactor, dropping acidic catalyst at 0 DGE C to 100 DEG C, aging for 1-10000h at 0 DGE C to 100 DEG C, and then adding photo-initiator. The method has the following characteristics of easy implementation and low cost, and is suitable for the surface modification field of different materials comprising metal, stone, ceramic, glass, polymer, and the like.

Owner:SOUTH CHINA UNIV OF TECH

A method of applying oxidized pe wax to circuit board sealing protection

ActiveCN109628018BOvercome the disadvantage of easy cracking at low temperatureOvercome the disadvantage of poor adhesionPrinted circuit detailsMacromolecular adhesive additivesElectrolysisPhysical chemistry

The invention relates to a method for applying oxidized PE wax to sealing protection of a circuit board. The method comprises the steps that the surface of the circuit board is coated with a layer ofcoupling agent, and air drying is conducted; the circuit board is dehumidified; a tackifier and a liquid toughening agent are added into the molten oxidized polyethylene wax to be uniformly mixed to prepare molten wax; the dehumidified circuit board is immersed in the molten wax for sealing, and after sealing is completed, the circuit board is placed on release paper and dried. By means of the sealing method, the defects that the oxidized PE wax easily cracks at the low temperature and has poor adhesion force are overcome; the tackifier and the toughening agent is added according to a ratio through repeated experiments, and finally, the oxidized PE wax can meet the requirement of the circuit board for effective waterproof and moisture-proof sealing in the working environment at minus 20-60DEG C. By means of the method, the good acid and alkali resistance, electrolytic-resistance chemical stability and hydrophobicity of the main ingredient PE wax are fully utilized, and a layer of waxfilm is formed on the surface of the circuit board and a component to protect the circuit board after melting.

Owner:康威通信技术股份有限公司

A protective film for digital electronic equipment and its processing technology

InactiveCN104960763BImprove wear resistanceImprove buffering effectFlexible coversWrappersTectorial membraneEngineering

The invention discloses a protective film for digital electronic equipment, comprising a plastic frame (1) integrally formed by injection molding and a rectangular substrate (2). ) of the annular connecting edge (3), the annular connecting edge (3) tightly wraps the edge of the substrate (2), and the edge of the substrate (2) is embedded in the interior of the annular connecting edge (3). Its processing technology is also disclosed. The beneficial effects of the present invention are: the present invention combines the advantages of glass materials and silica gel materials (including plastics such as silica gel, pet, abs, pp, pc, etc.), and can not only play a good protective role, but also reduce the thickness of the protective film, It has good transparency; the processing method of high-precision mold injection molding or die-casting plastic frame around the glass substrate ensures a good connection structure between the glass substrate and the plastic frame, and overcomes the disadvantage of poor adhesion between glass and silicone materials.

Owner:李灵敏

Matched coating for aluminium alloy base material

ActiveCN100352873COvercome the disadvantage of poor adhesionBoth hardnessLiquid surface applicatorsPolyurea/polyurethane coatingsChain lengthEpoxy amine

The matched coating for aluminum alloy base material special to corrosion protection and decoration comprises: the primer with epoxy-amine addition system as double constituents, the middle painting as polyester / polyurethane system used polyester resin with acid number of as 8-10 and alternative soft and hard chain segments, and the top coat used polyester resin with acid number not more than 6 and main chain as hard segment and chain length and branching degree both more than the middle. Wherein, the polyamine on primer reacts with the epoxy resin to produce the secondary amine with more slow activity and enhance the adhesive force. This invention solves the aluminum alloy adhesion problem without smoke resistant material, and comes up to the first-level security standard.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

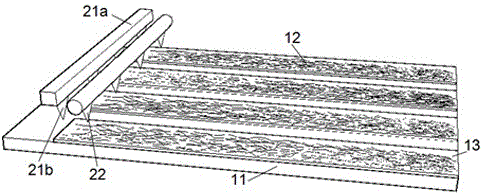

A kind of preparation method of transparent conductive material based on 3D printing technology

ActiveCN104409170BGood light transmissionImprove conductivityCable/conductor manufactureSpecial data processing applicationsLiquid jetModeling software

The invention relates to a preparation method of a transparent conducting material based on a 3D printing technology. The preparation method is characterized by comprising the following steps of 1) modeling; designing a model of a strip transparent conducting electrode by utilizing computer modeling software, and converting a software command of the model to a mechanical equipment directive of 3D printing so as to control the moving path, the movement speed and the liquid jet velocity of each 3D printing head as well as the moving path, the movement speed and the laser irradiation time of each laser head; and 2) printing the strip transparent conducting electrode. The transparent conducting electrode prepared by the invention has the advantages of good light transmittance and good electrical conductivity and overcomes the defect of poor adhesiveness of between a carbon nano-tube film layer and a substrate and between a graphene film layer and the substrate; and by adopting the method, the thickness and the width of the transparent conducting electrode are precisely controlled.

Owner:FUZHOU UNIV

A kind of preparation method of high solar energy absorption rate and high emissivity black matting film layer on the surface of titanium alloy

ActiveCN105177672BOvercome the disadvantage of poor adhesionImprove bindingSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

Owner:HARBIN INST OF TECH

Ultrathin water-based epoxy resin expandable fireproof paint and preparation method thereof

InactiveCN101712840BEnvironmentally friendlyCorrosion resistanceFireproof paintsEmulsion paintsWater basedEpoxy

The invention relates to an ultrathin water-based epoxy resin expandable fireproof paint and a preparation method thereof, belonging to the technical field of plating metal materials. The fireproof paint comprises water, aqueous epoxy emulsion, a solidification agent, ammonium polyphosphate, a charring foaming agent, a charring accelerant, nano fillers, inorganic fireproof fillers, a dispersing agent, a defoaming agent and a thickening agent. A ball milling machine is adopted for preparing a double-component paint; component A is prepared by two steps of: (1) dispersing the ammonium polyphosphate, the charring foaming agent, the charring accelerant, the nano fillers and the inorganic fireproof fillers in the water by the dispersing agent, with the milling time of 1 to 2 hours; and (2) adding the solidification agent and the defoaming agent for continuously milling for 0.5 to 1 hour; and component B is prepared by one step of: milling the aqueous epoxy emulsion, the thickening agent and the defoaming agent for 0.5 to 1 hour. When the coating thickness of the fireproof paint is smaller than or equal to 1mm, the fireproof time is larger than 90 minutes, the maximum smoke density is smaller than 50, and the adhesion force is larger than or equal to 12MPa. The invention has the advantages of simple preparation process, environmental protection and excellent performance, and can be used for the fire safety protection of the inner parts of large steel structures of buildings, ships, oil storage tanks and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of preparation method of transparent conductive film for flexible display

ActiveCN108682616BHigh transparencyColorless propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesImidePolymer science

The invention discloses a transparent and colorless conductive film for a flexible display. The preparation method comprises the following steps: first, using a diamine monomer comprising 2,2-bis[4-(4-aminophenoxy phenyl)]hexafluoropropane as a main component and a dianhydride monomer comprising 4, 4'-(p-phenylenedioxy)bis(phthalic anhydride) as a main component to react to obtain a polyamide acidsolution, then adding nanoscale barium ruthenate powder subjected to sintering at a high temperature of over 1700 DEG C, thereby obtaining a mixed solution, and performing imidization on a film obtained after removing solvents from the mixed solution, thereby obtaining the colorless transparent conductive film for a flexible display. The conductive film obtained by the invention is obtained by using a transparent and colorless flexible polyimide material as a matrix and adding high-conductivity BaRuO3 powder, and overcomes the defects of relatively poor flexibility of a traditional transparent conductive layer of ITO, nano silver wire, graphene and the like used in a flexible display, poor adhesion to the flexible substrate, and the like. At that same time, the problem that the transparency of the composite film obtained by adding conductive filler to a common polyimide matrix is poor and a conductive effect is not ideal is solved.

Owner:NANJING UNIV OF SCI & TECH

A kind of preparation method of titanium alloy ta2 surface high solar absorption rate low emissivity film layer

ActiveCN105040070BOvercome the disadvantage of poor adhesionImprove bindingSurface reaction electrolytic coatingTitanium surfaceSolar absorptance

The invention discloses a method for preparing a film layer with high solar absorption rate and low emissivity on the surface of titanium alloy TA2, which relates to a method for preparing a ceramic film layer on the surface of titanium alloy TA2. The purpose of the invention is to solve the problems of low solar energy absorption rate, high self-emission rate and low bonding force between the film layer and the substrate in the coating on the surface of the existing titanium alloy TA2. Method: pretreatment of titanium alloy TA2; second, micro-arc oxidation to obtain a high solar absorption rate and low emissivity film on the surface of titanium alloy TA2. The thickness of the high solar absorptivity and low emissivity film layer on the surface of the titanium alloy TA2 prepared by the present invention is 0.3 μm to 1 μm, the roughness of the film layer is 0.2 μm to 0.25 μm, the solar absorptivity is 0.82 to 0.9, and the emissivity is 0.08 to 0.08 μm. 0.13. The invention can obtain a method for preparing a film layer with high solar absorption rate and low emissivity on the surface of titanium alloy TA2.

Owner:HARBIN INST OF TECH

Method for preparing transparent conductive film of flexible display

ActiveCN108682616AHigh transparencyColorless propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesComposite filmDisplay device

The invention discloses a transparent and colorless conductive film for a flexible display. The preparation method comprises the following steps: first, using a diamine monomer comprising 2,2-bis[4-(4-aminophenoxy phenyl)]hexafluoropropane as a main component and a dianhydride monomer comprising 4, 4'-(p-phenylenedioxy)bis(phthalic anhydride) as a main component to react to obtain a polyamide acidsolution, then adding nanoscale barium ruthenate powder subjected to sintering at a high temperature of over 1700 DEG C, thereby obtaining a mixed solution, and performing imidization on a film obtained after removing solvents from the mixed solution, thereby obtaining the colorless transparent conductive film for a flexible display. The conductive film obtained by the invention is obtained by using a transparent and colorless flexible polyimide material as a matrix and adding high-conductivity BaRuO3 powder, and overcomes the defects of relatively poor flexibility of a traditional transparent conductive layer of ITO, nano silver wire, graphene and the like used in a flexible display, poor adhesion to the flexible substrate, and the like. At that same time, the problem that the transparency of the composite film obtained by adding conductive filler to a common polyimide matrix is poor and a conductive effect is not ideal is solved.

Owner:NANJING UNIV OF SCI & TECH

A kind of preparation method of concrete silane paste impregnation waterproofing agent

The invention provides a preparation method for a concrete silane paste impregnation waterproof agent, relates to a preparation method for an impregnation waterproof agent, and aims to solve the problems that the adhesion of existing liquid silane and silane emulsion is poor. The preparation method comprises the following steps: 1, weighing; 2, mixing to obtain a mixed solution; 3, performing initial reaction to obtain a reactant; 4, emulsifying to obtain the concrete silane paste impregnation waterproof agent. The preparation method has the advantages that the shortcoming of poor adhesion of liquid silane and silane emulsion is overcome, the construction is convenient, and multiple construction manners such as spraying, brushing and roll coating can be adopted for coating of vertical surfaces, so that the loss of active substances is reduced; the permeability of a pore structure of the material per se can be maintained; the waterproofness and permeability of the concrete silane paste impregnation waterproof agent are better than those of liquid silane and silane emulsion, the water absorption of a concrete structure can be reduced by 90% or above, the penetration depth of silane is increased, and silane can penetrate into the concrete surface at 3-4 mm. The method is mainly used for preparation of the concrete silane paste impregnation waterproof agent.

Owner:HARBIN INST OF TECH

A kind of environment-friendly rosin-based fluorine-free waterproofing agent and preparation method thereof

ActiveCN106120349BIncrease profitReduce dependenceLiquid repellent fibresEnvironmental resistanceFiber

The invention relates to a rosinyl fluoride-free waterproof agent and a preparation method thereof. The rosinyl fluoride-free waterproof agent is prepared from the following raw materials in parts by weight: 10-100 parts of rosin-modified silicon wax, 5-20 parts of polyether urethane resins, 5-20 parts of cross-linking agents, 1-15 parts of emulsifying agents, 10-200 parts of solvents and 100-300 parts of water. The rosinyl fluoride-free waterproof agent provided by the invention is arranged as an environment-friendly waterproof agent; the waterproof agent is free from fluorocarbon compound; the defect of poor dynamic siphon-proof property of the fluoride-free waterproof agent in the prior art is overcome; the rosinyl fluoride-free waterproof agent has excellent static siphon-proof property; the defect of poor adhesive force of the waterproof agent product and superfine fiber synthetic leather base cloth in the prior art is overcome; the green reproducible natural rosin or ramification thereof is taken as the raw material, so that the waterproof agent has an important value of environmental protection and ultra-wide application prospect; the preparation is simple and environment-friendly.

Owner:太仓中化环保化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com