Method for applying oxidized PE wax to sealing protection of circuit board

A circuit board, oxidized polyethylene wax technology, applied in the directions of printed circuit parts, adhesive additives, polymer adhesive additives, etc., to achieve the effects of good acid and alkali resistance, simple sealing method, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

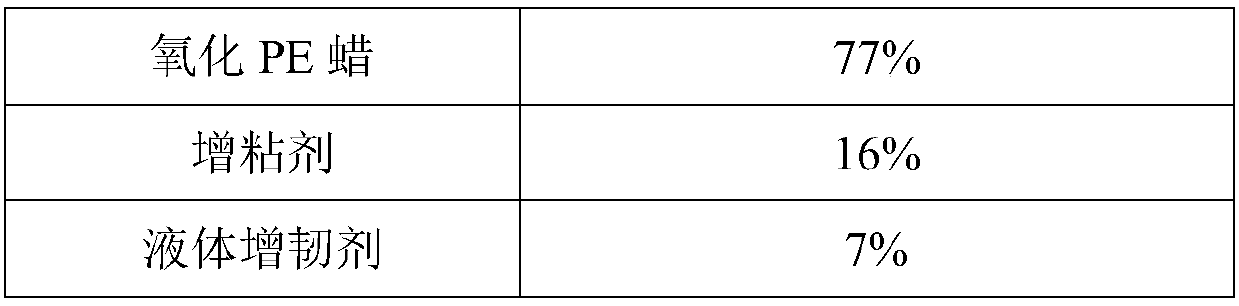

[0045] The basic composition of the composite wax liquid is shown in Table 1:

[0046] Table 1

[0047]

[0048]

[0049] Oxidized PE wax: make full use of its hydrophobicity and chemical stability, and form a layer of PVC film on the surface after heating and curing, which has excellent waterproof, moisture-proof and mildew-proof performance.

[0050] Tackifier: Make full use of its adhesive properties to increase the adhesion of the main material oxidized PE wax to circuit boards and components.

[0051] Toughening agent: make full use of its excellent toughness at low temperature to solve the problem that the wax film of oxidized PE wax is easy to crack during low temperature and thermal expansion and contraction.

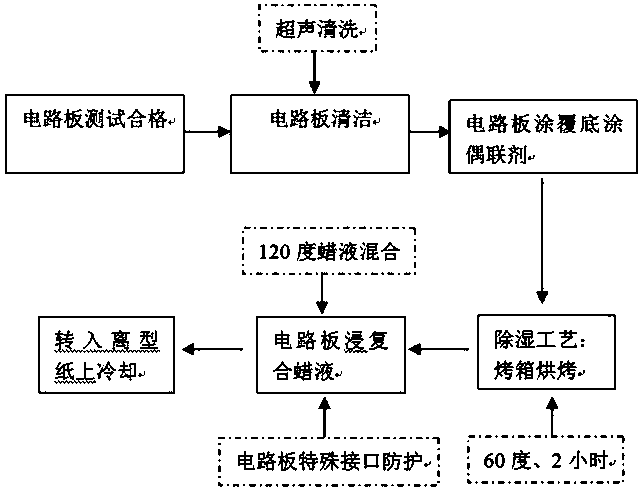

[0052] The process flow of circuit board waterproof treatment is as follows:

[0053] There are three important links in the whole waterproof treatment process, namely circuit board pretreatment, dip coating and cooling.

[0054] The first step of pretr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com