Preparation method for concrete silane paste impregnation waterproof agent

A waterproofing agent and concrete technology, which is applied in the field of preparation of impregnated waterproofing agent, can solve the problems of poor adhesion of liquid silane and emulsion silane, etc., and achieve the effect of increasing penetration depth, economical and reasonable, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

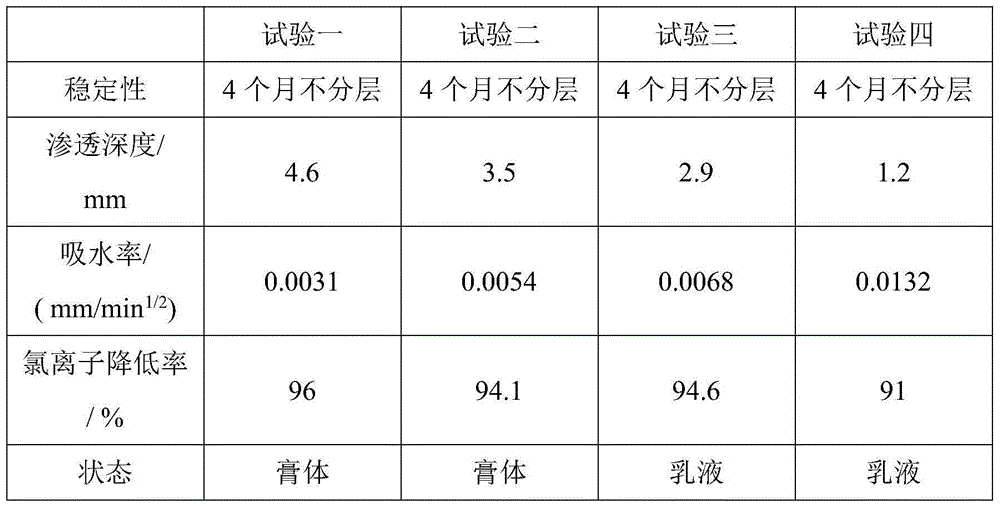

[0010] Embodiment 1: This embodiment is a method for preparing concrete silane paste impregnated with waterproofing agent, which is specifically completed according to the following steps:

[0011] 1. Weighing: Weigh 50-80 parts by weight of n-octyltriethoxysilane, 1-6 parts of octadecylamine polyoxyethylene ether, 1-10 parts of isotridecanyl polyoxyethylene ether, 0.15 ~2 parts of triethylamine, 1~6 parts of sodium dodecylbenzenesulfonate, 0.1~2 parts of polyethylene glycol 6000, 0.1~0.5 parts of bactericide, 0.1~0.5 parts of defoamer and 20~50 parts of water ; 2. Mixing: Add 1 to 6 parts of octadecylamine polyoxyethylene ether, 1 to 10 parts of isotridecanyl polyoxyethylene ether and 1 to 6 parts of sodium dodecylbenzenesulfonate as a compound emulsifier to 20 ~50 parts of water, stirring and mixing at a stirring speed of 300rpm~500rpm, while stirring and mixing starts, the temperature is raised from room temperature to 50~70°C, and after the temperature is raised to 50~70°C...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, weigh 60-80 parts of n-octyltriethoxysilane, 1-6 parts of octadecylamine polyoxyethylene Ether, 1-10 parts of isotridecanyl polyoxyethylene ether, 0.15-2 parts of triethylamine, 1-6 parts of sodium dodecylbenzenesulfonate, 0.1-2 parts of polyethylene glycol 6000, 0.1-0.5 parts Fungicide, 0.1-0.5 parts of defoamer and 20-40 parts of water. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 60-80 parts of n-octyltriethoxysilane and 2-5 parts of octadecylamine are weighed in parts by weight Polyoxyethylene ether, 2-6 parts of isotridecanyl polyoxyethylene ether, 0.15-2 parts of triethylamine, 1-3 parts of sodium dodecylbenzenesulfonate, 0.1-2 parts of polyethylene glycol 6000, 0.1 parts ~0.5 parts of fungicide, 0.1~0.5 parts of defoamer and 20~40 parts of water. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com