Ultrathin water-based epoxy resin expandable fireproof paint and preparation method thereof

A water-based epoxy resin and fireproof coating technology, applied in epoxy resin coatings, fireproof coatings, coatings, etc., can solve the problems of high organic volatile matter, thick coating application performance, low fireproof efficiency, etc., and achieve enhanced insulation. The effect of thermal refractory performance, excellent adhesion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

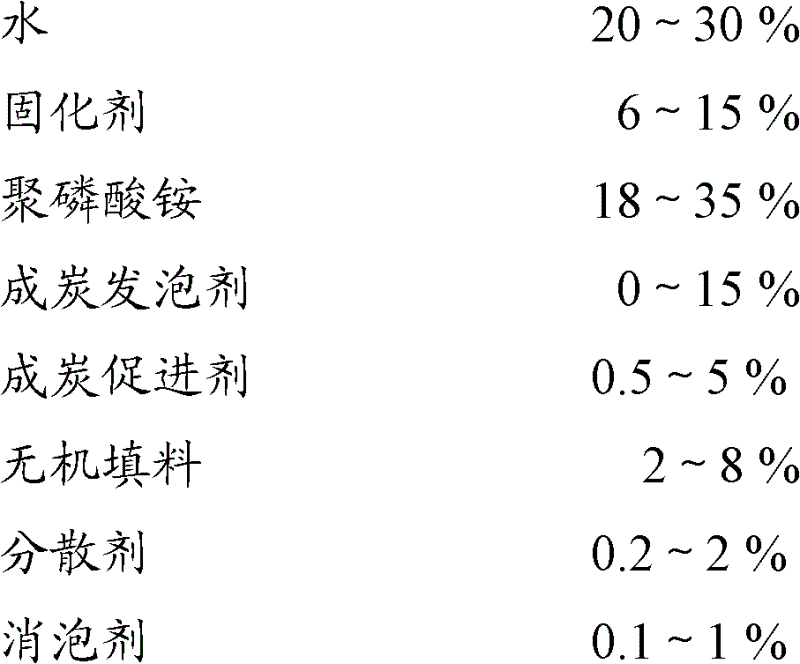

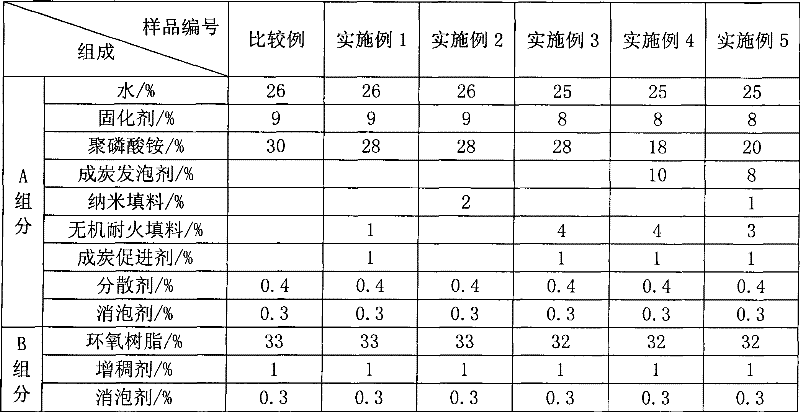

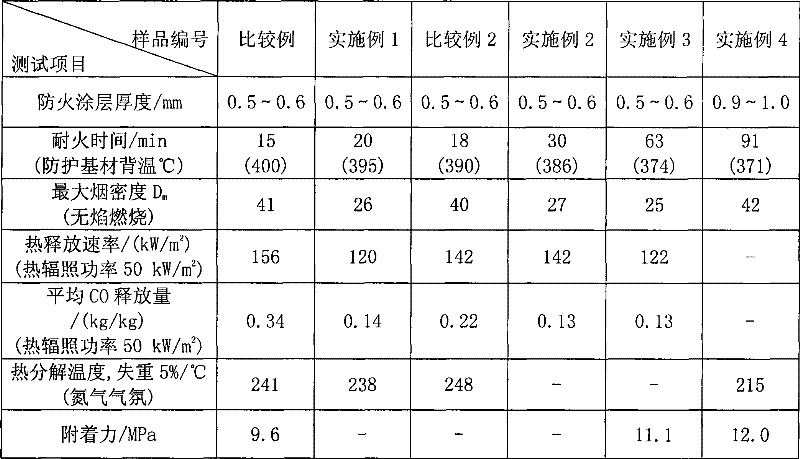

[0045] By weight percent example (see Table 1) and above-mentioned preparation technology of the embodiment formula component of ultra-thin waterborne epoxy resin expansion type fireproof coating of the present invention, prepare component A and component B respectively; And by table 1 embodiment formula The weight percentage of the components is fully mixed with component A and component B to obtain an ultra-thin intumescent fireproof coating, and the intumescent fireproof coating is scraped and coated on one side of a 100mm×100mm×1mm steel plate for several times by the scraping method, and dried at room temperature , form a coating with a thickness of 0.5-1.0mm, and the curing time is 7-10 days, and prepare the samples of the ultra-thin epoxy resin intumescent fireproof coating of the embodiment respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com