Infrared detector manufacturing method based on compound sacrificial layers

A technology of infrared detector and composite sacrificial layer, applied in the field of infrared detector, can solve the problems of peeling, inability to achieve planarization, poor adhesion of metal layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

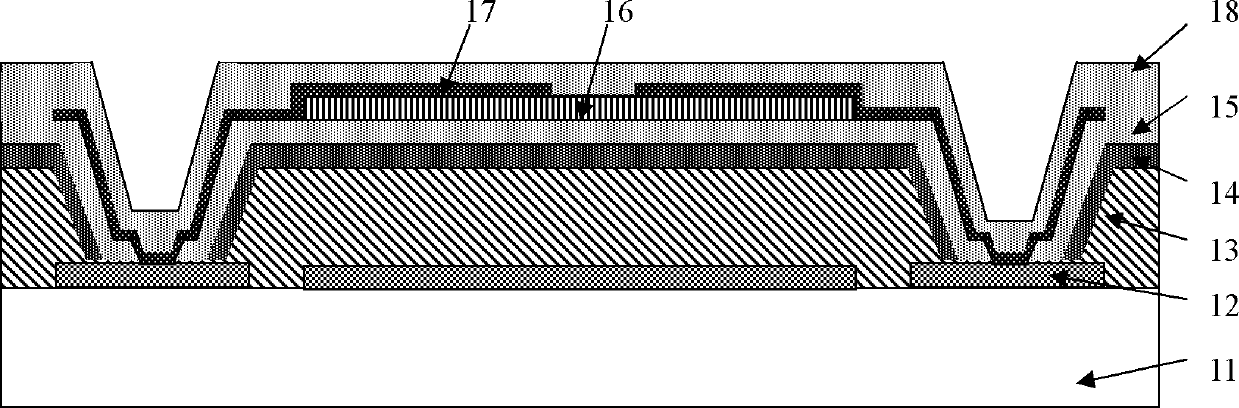

[0068] Figure 2 is figure 1 The flow chart of the first processing method of the infrared detector is shown. The infrared detector processing method of the present invention will be described in detail below in conjunction with FIG. 2 , and the present invention will be further described.

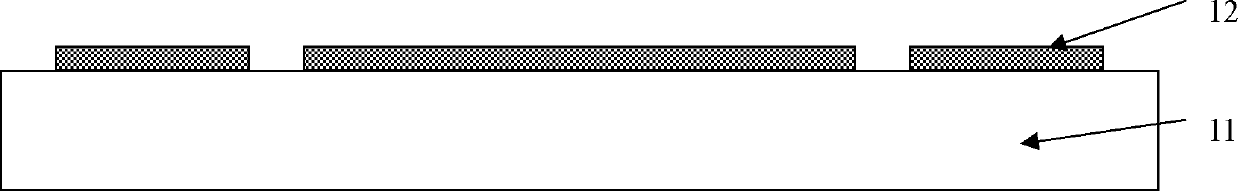

[0069] 2(a), fabricating and patterning the metal layer 12 on the substrate 11 to form an infrared reflection layer and an electrical connection with CMOS. Wherein, the substrate 11 is a silicon wafer that has been processed with CMOS circuits. One of Ti / TiN / Al (alloy including Al), TiW / Al (alloy including Al), and Ta / TaN / Al (alloy including Al) is used for the metal reflective layer 12 . The thickness of the control metal layer 12 is between 1000A~10000A.

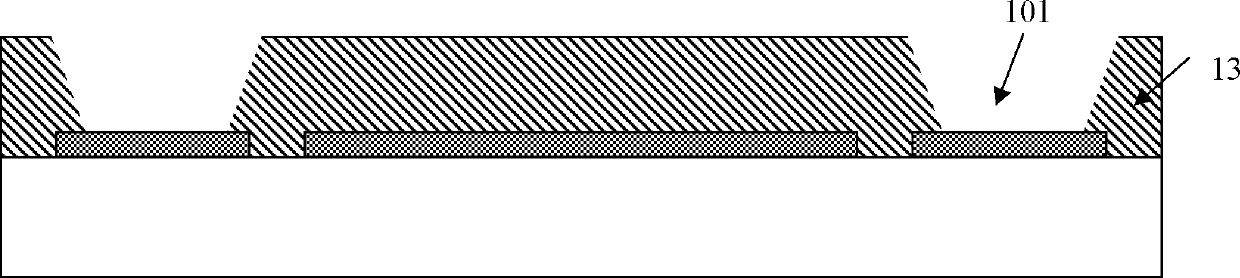

[0070] 2(b), making a first sacrificial layer 13 of polyimide on the metal layer 12, which is prepared by a spin-coating method. In this embodiment, the polyimide is photosensitive, and through-holes 101 are formed by exposure and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com