A Foil Positioning, Cutting and Forming Device

A forming device and foil technology, applied in transportation and packaging, thin material handling, sending objects, etc., can solve the problems of foil surface flattening, positioning cutting, adverse effects, etc., to reduce adverse effects and smooth the surface , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

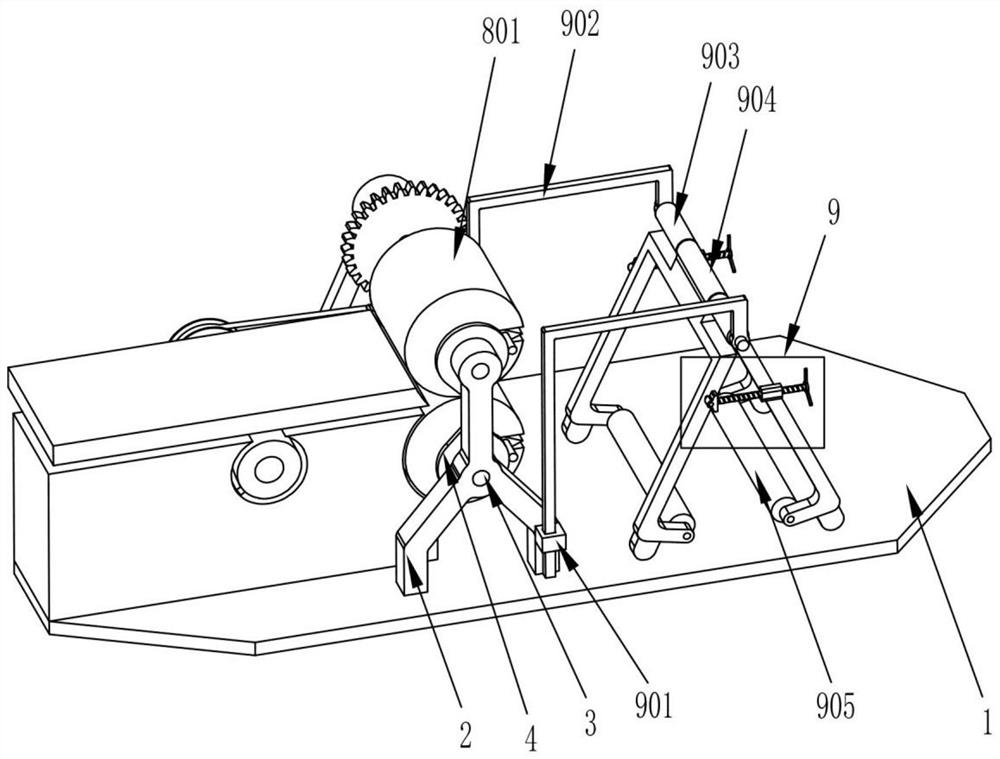

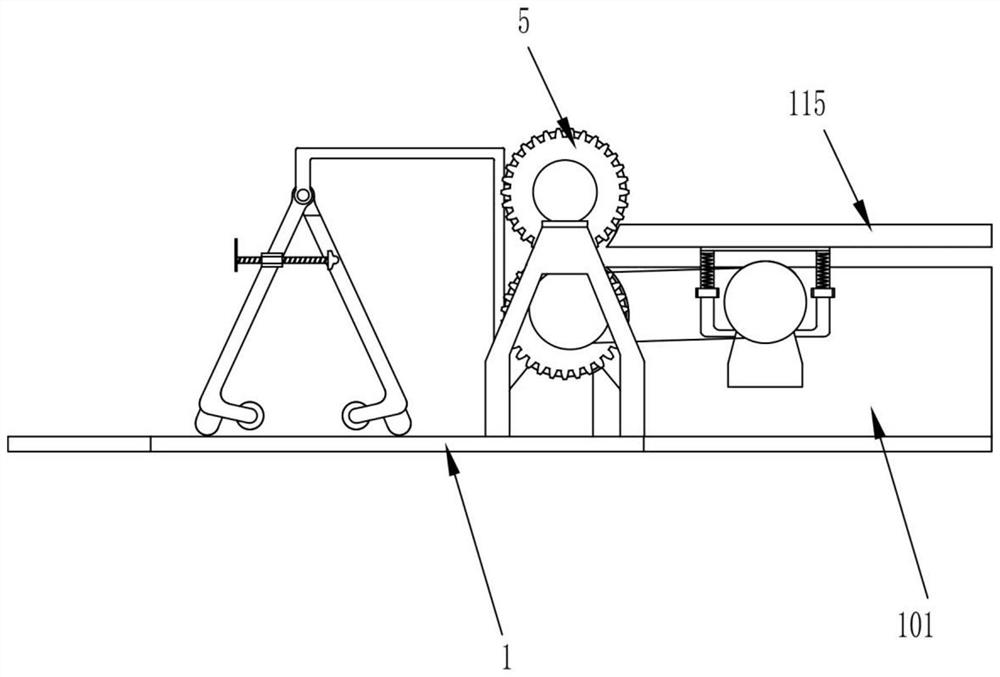

[0024] A foil positioning truncation forming device, such as Figure 1-8 As shown, it includes a base plate 1, a bracket 2, a rotating shaft 3, a fixed cam 4, a gear 5, a mounting frame 6, a driving motor 7, a cutting mechanism 8 and a foil clamping mechanism 9, and the upper side of the base plate 1 is fixedly installed with Two supports 2 that are symmetrically arranged, two rotating shafts 3 are installed by bearings on the two supports 2, two fixed cams 4 are fixedly installed on the two supports 2 and the two rotating shafts 3 pass through the circular holes in the middle of the fixed cam 4, and the two One end of the rotating shaft 3 is equipped with a gear 5 and the two gears 5 mesh with each other. The mounting frame 6 is fixedly mounted on the upper side of the bottom plate 1 and is close to one of the brackets 2. The driving motor 7 is fixedly mounted on the mounting frame 6 The upper side of the drive motor 7 and the output shaft of the drive motor 7 are fixedly con...

Embodiment 2

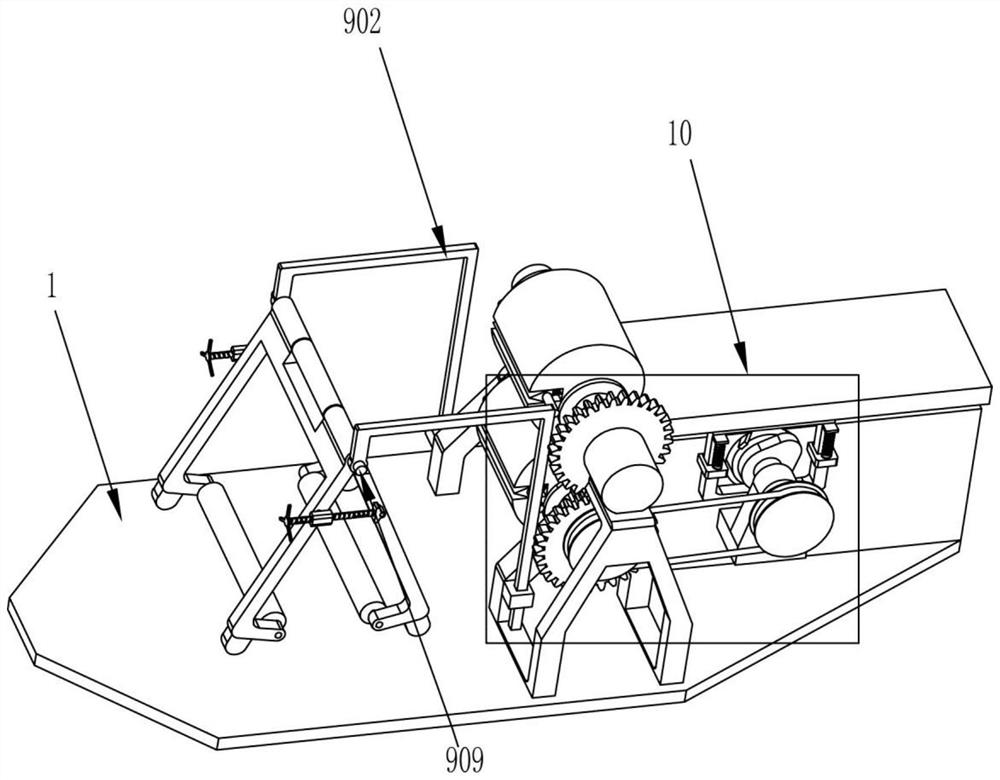

[0030] On the basis of Example 1, such as Figure 2-3 and Figure 7-8 As shown, it also includes a conveying mechanism 10 for conveying the cut foil. The conveying mechanism 10 is installed on the upper side of the bottom plate 1 and is close to the cutting mechanism 8. The conveying mechanism 10 includes a support seat 101, a fixed Plate 102, power transmission shaft 103, first pulley 104, second pulley 105, transmission belt 106 and push wheel 107, described support base 101 is fixedly installed on the upper side of base plate 1 and offers a circular recess on support base 101 slot, the fixed plate 102 is fixedly installed on one side of the support base 101 and is located above the bottom plate 1, the transmission shaft 103 is mounted on the fixed plate 102 through a bearing, and the first pulley 104 is installed on the drive shaft 103 One end, the second pulley 105 is installed on one end of the other rotating shaft 3, a transmission belt 106 is connected between the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com