Preparation method for concrete silane paste waterproofing agent

A technology of waterproofing agent and concrete, which is applied in the field of preparation of concrete silane waterproofing agent, which can solve the problems of coating failure, surface coating damage, and inability to guarantee the air permeability of concrete materials, etc., and achieves small volatilization, increased penetration time, and good waterproof effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

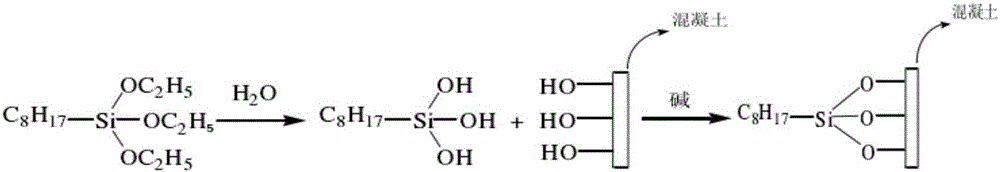

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

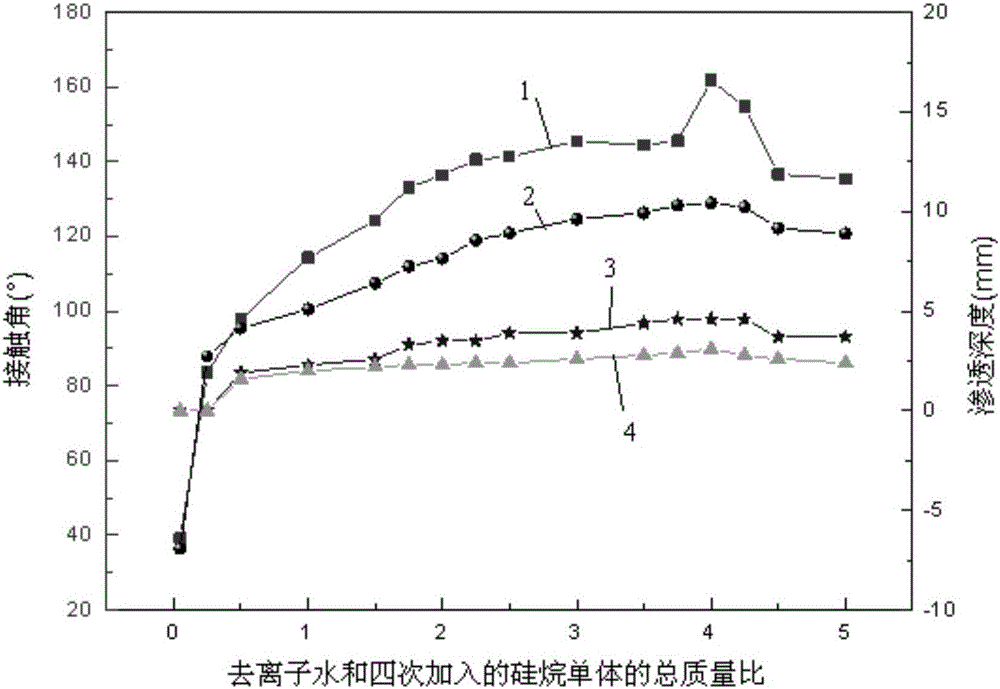

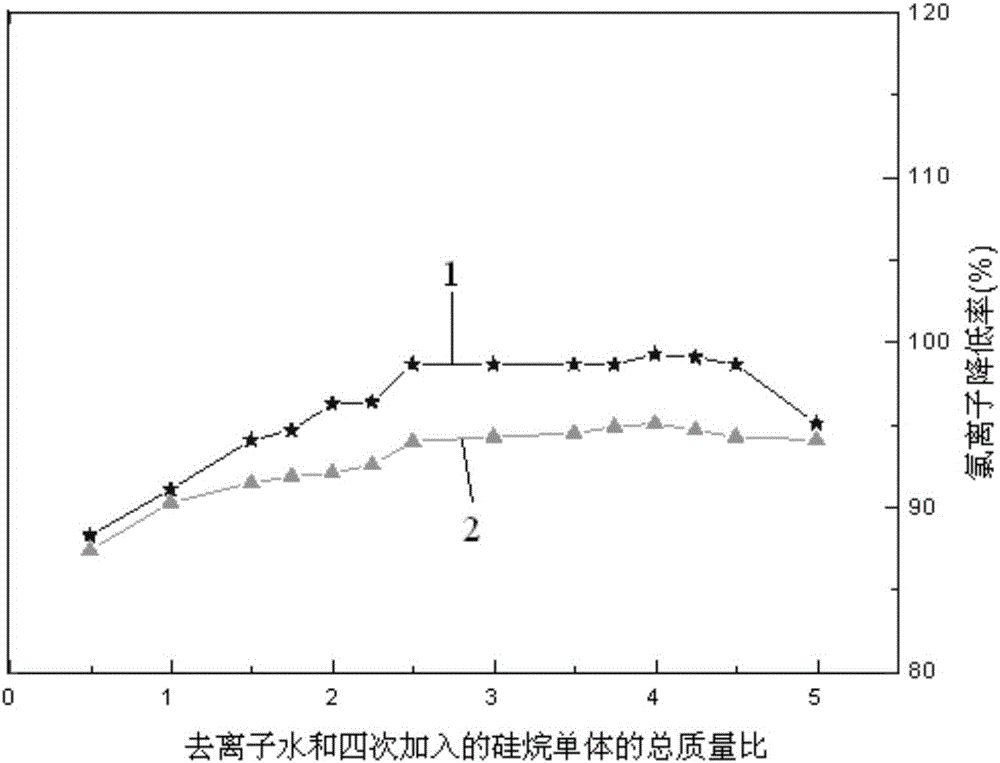

[0025] Embodiment 1: This embodiment is a method for preparing a concrete silane paste waterproofing agent, which is specifically carried out according to the following steps:

[0026] Add deionized water and compound emulsifier into the three-necked bottle, stir at a speed of 400rpm and a temperature of 60°C to 80°C until the compound emulsifier is completely dissolved, then add amino silicone oil and triethylamine, and add in four times Silane monomer, then stirred at 60°C-80°C for 12h-16h, naturally cooled to room temperature, added phosphoric acid until the pH was 7-9, added stabilizer and bactericide, and used a high-speed emulsifier at a speed of 3000rpm Emulsified under the condition of 0.5h~1h, obtain concrete silane paste waterproofing agent; The mass ratio of described composite emulsifier and deionized water is 1:(8~9); The quality of described amino silicone oil and composite emulsifier Ratio is 1:3; The mass ratio of described triethylamine and composite emulsifie...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the composite emulsifier is made of stearylamine polyoxyethylene ether, isotridecanyl polyoxyethylene ether and sodium laurylsulfonate The three are of equal quality. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the silane monomer is one or a mixture of n-octyltriethoxysilane and propyltriethoxysilane ; When the silane monomer is the mixture of n-octyltriethoxysilane and propyltriethoxysilane, the mass ratio of propyltriethoxysilane and n-octyltriethoxysilane is (0.15 ~ 1): 1. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com