Preparation method for anti-rust soap-free acrylate emulsion

An acrylate and anti-rust emulsion technology, which is applied in anti-corrosion coatings, coatings, etc., can solve the adverse effects of emulsion products on weather resistance, stain resistance, and water resistance, and it is difficult to prevent oxygen and moisture from permeating, and polymer coatings Water resistance decline and other problems, to achieve the effect of excellent performance, excellent weather resistance, enhanced wettability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of soap-free acrylate antirust emulsion, comprises the steps (pre-emulsification dropping monomer method):

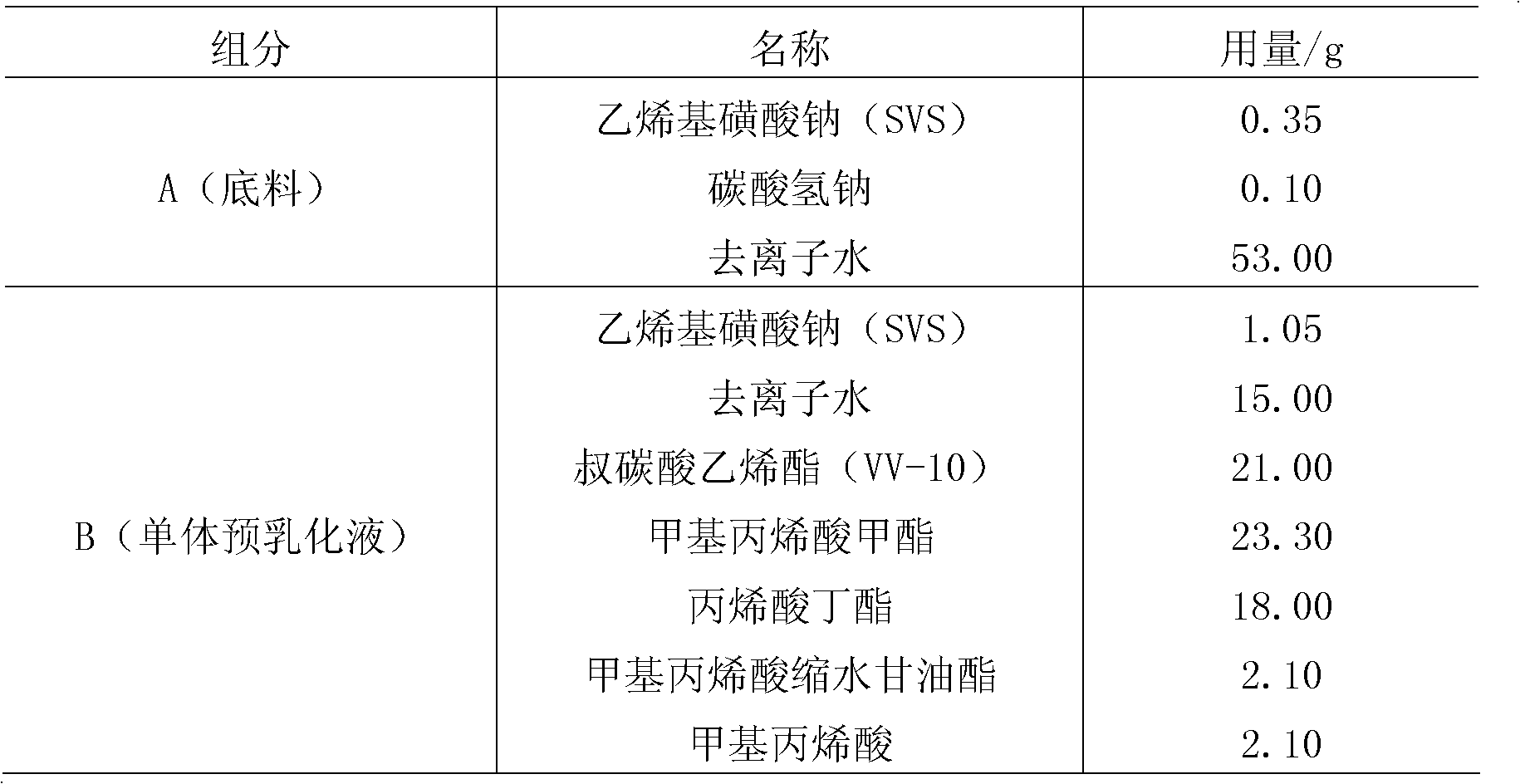

[0037] 1) The composition and dosage of raw materials are as follows:

[0038]

[0039]

[0040] 2) Mix and dissolve 15.00g deionized water and 1.05g sodium vinyl sulfonate in a pre-emulsification tank, then slowly add the following three kinds under stirring: ① 23.30g methyl methacrylate, 18.00g butyl acrylate ester and 2.10g methacrylic acid, ②21.00g tertiary vinyl carbonate, ③1.40g methacrylic acid polyether phosphate, stirred for 10-15min to obtain monomer pre-emulsion, and set aside;

[0041] 3) add 53.00g deionized water, 0.35g remaining sodium vinyl sulfonate and 0.10g sodium bicarbonate (buffering agent ), stirring and heating up to 80-85°C to obtain the bottom material;

[0042] 4) Take 8.185g of monomer pre-emulsion and add it to the bottom material (that is, in the reactor), stir, add 0.06g of reaction initiator (prelimin...

Embodiment 2

[0054] The preparation method of soap-free acrylate antirust emulsion, comprises the steps (direct drop monomer method):

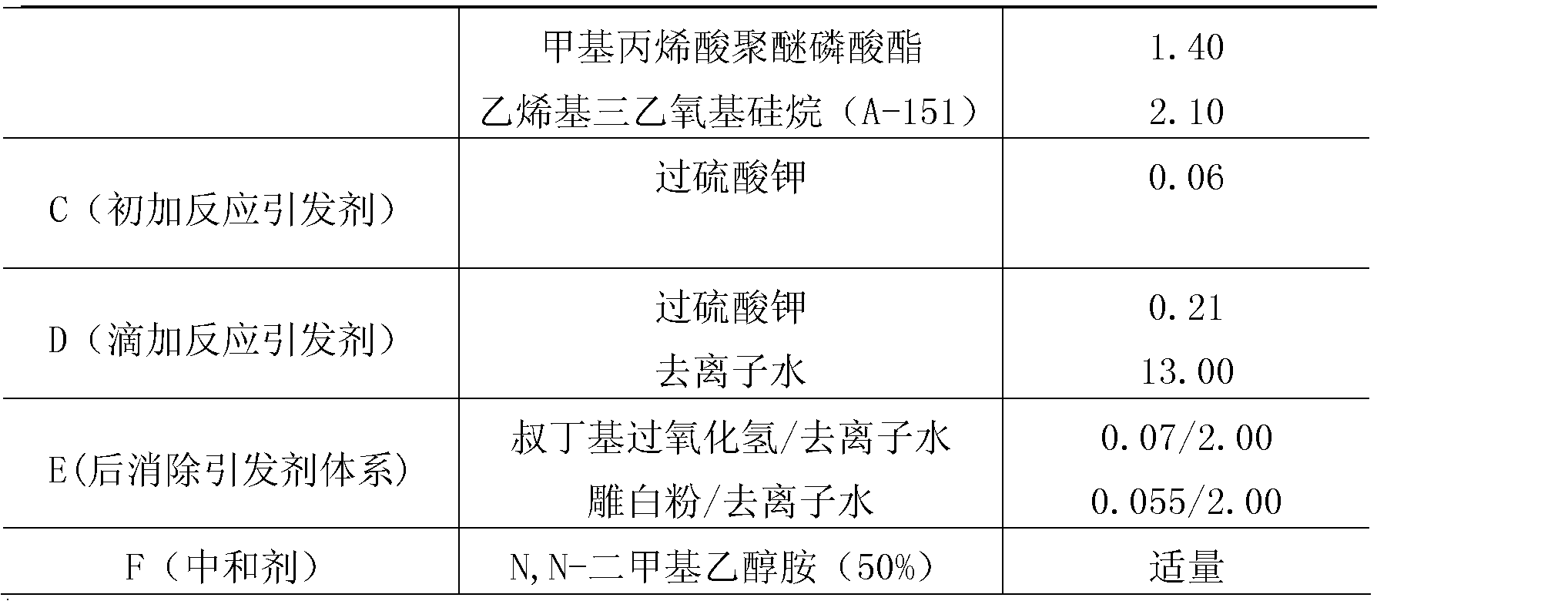

[0055] 1) The composition and dosage of raw materials are as follows:

[0056]

[0057] 2) Stir and mix 25.00g methyl methacrylate, 17.50g butyl acrylate, 2.10g methacrylic acid, 21.00g tertiary vinyl carbonate and 1.40g methacrylic acid polyether phosphate to prepare monomer mixture for later use;

[0058] 3) Add 68.00g deionized water, 1.40g sodium vinylsulfonate and 0.10g sodium bicarbonate (buffering agent) in the reactor (four-necked flask equipped with condenser, stirrer, thermometer, dropping funnel), Stir and heat up to 80-85°C to obtain the base material;

[0059] 4) Take 6.7g of the monomer mixture and add it to the bottom material (that is, in the reactor), stir, add 0.06g of reaction initiator (preliminary addition of reaction initiator); add 13.00g of deionized water to the remaining 0.21g of reaction initiator Make up the remaining react...

Embodiment 3

[0070] The preparation method of soap-free acrylate antirust emulsion, comprises the steps:

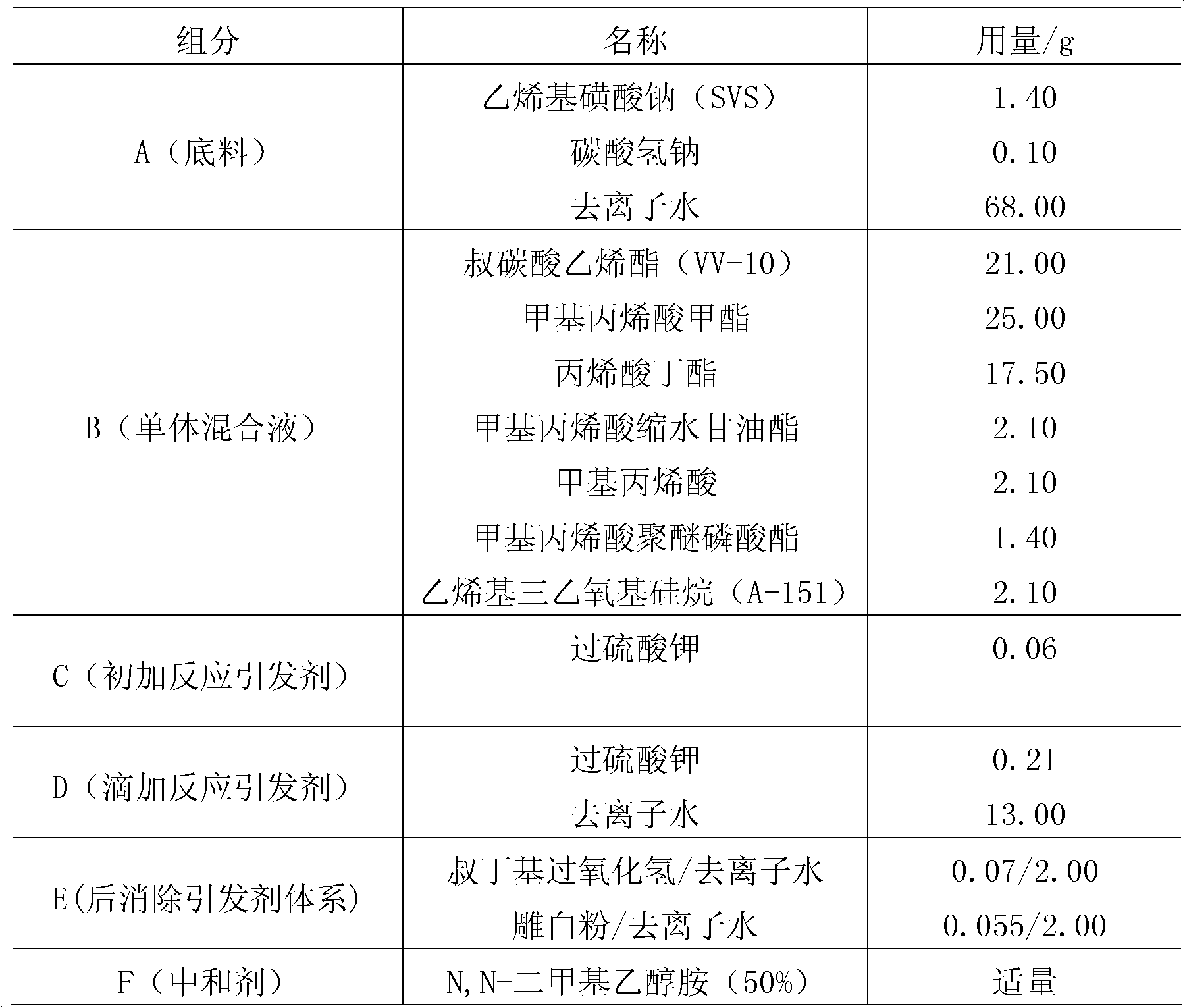

[0071] The composition and consumption of raw materials are as follows:

[0072]

[0073] Concrete steps and process are with embodiment 1.

[0074] Product technical indicators:

[0075] Appearance: milky white, blue light is obvious, emulsion is clear

[0076] Solid content: 45.5%

[0077] Dosage of reactive emulsifier (total amount of monomer): 3%

[0078] Vinyl tert-carbonate content (total amount of monomer): 25%

[0079] Phosphate content (total amount of monomers): 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com