A protective film for digital electronic equipment and its processing technology

A technology of electronic equipment and protective film, applied in the field of protection products of a new protection method, can solve the problems of imperfect protection of the touch screen, inability to achieve the protection effect, affecting the appearance of the appearance and other problems, and achieve good protection effect and good anti-fall. good performance, good buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

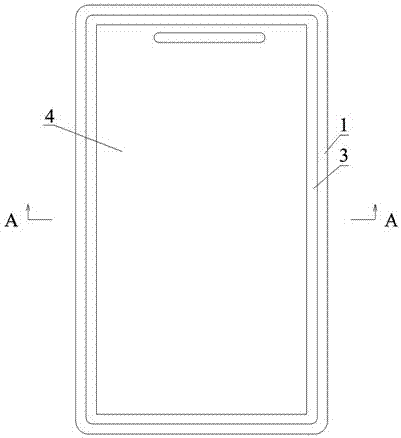

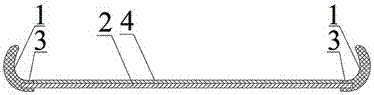

[0021] Such as figure 1 , figure 2 As shown, a protective film for digital electronic equipment includes a plastic frame 1 integrally formed by injection molding and a rectangular substrate 2. The bottom of the plastic frame 1 has an annular connection edge 3 for mounting the substrate 2, and the annular connection The edge 3 tightly wraps the edge of the substrate 2 , and the edge of the substrate 2 is embedded in the interior of the annular connection edge 3 .

[0022] Further, the part of the upper surface of the substrate 2 not covered by the plastic frame 1 is coated with an AB adhesive layer 4 for connecting the substrate 2 and the digital device.

[0023] The substrate 2 is a glass substrate 2 made of glass.

[0024] The thickness of the substrate 2 is 0.1-0.55mm, and the thickness of the AB adhesive layer 4 is 0.07-0.55mm.

[0025] The digital electronic device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com