MWT cell, MWT cell hole filling slurry, frit and frit raw material composition

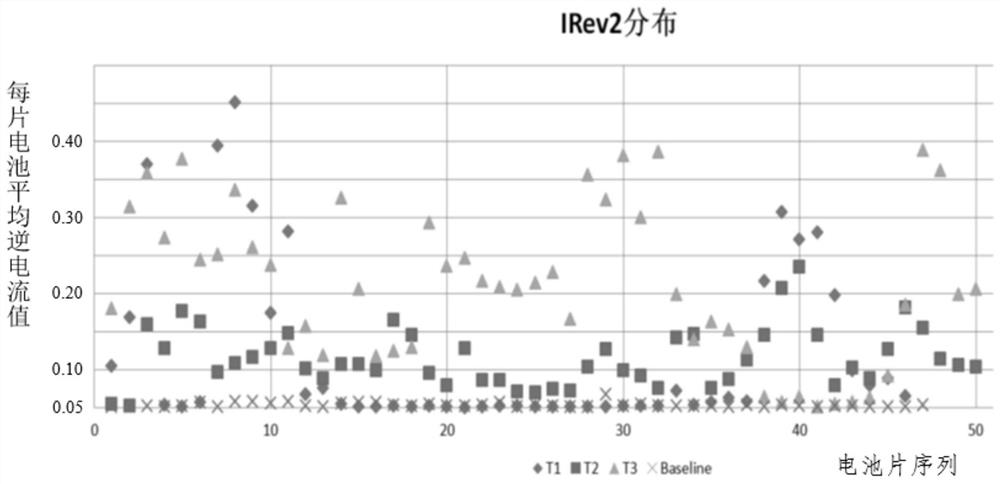

A technology of glass frit and composition, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor adhesion of conductive paste, and achieve the effects of no influence of steady-state leakage, small damage, and avoid falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This embodiment provides a glass frit of a MWT battery filling paste, a MWT battery filling paste, and a MWT battery.

[0075] The glass frit of MWT battery filling paste is mainly prepared through the following steps:

[0076] Raw materials are configured according to the following mass percentages: P 2 o 5 73.35%, CuO 4%, MgO 5.86%, CaO 7.99%, SiO 2 6.3% and K 2 O 2.5%.

[0077] Fully mix the weighed raw materials, put the mixed mixture into a platinum crucible, then put it into an electric furnace with a furnace temperature of 1300°C, and keep it warm for 1 hour; pour the melted glass liquid into a tablet press and press it into thin slices Then put the flake glass into a ball mill for ball milling; sieve the milled glass powder to obtain glass frit.

[0078] MWT battery hole filling slurry is mainly prepared through the following steps:

[0079] Raw materials are configured according to the following mass percentages: 8.8% organic vehicle, 88.5% silver powde...

Embodiment 2

[0087] Embodiment 2 also provides a MWT battery hole filling slurry and a MWT battery.

[0088] The difference between Example 2 and Example 1 lies in that the raw materials of the MWT battery hole filling slurry are different.

[0089] In Example 2, the raw materials of the MWT battery hole filling slurry mainly include the following components in terms of mass percentage:

[0090] The organic vehicle of 8.8%, the silver powder of 87.5%, the zinc powder of 1.5% and the glass frit of the embodiment 1 of 2.2% provide the MWT battery filling paste; Wherein, organic vehicle is the ethyl cellulose of 20wt%, 20wt% acrylic acid Resin, 40 wt% butyl carbitol, 20 wt% butyl carbitol acetate.

[0091] The MWT battery of this example is prepared by the same method as that of Example 1.

Embodiment 3

[0093] Embodiment 3 also provides a glass frit of a MWT battery hole filling paste, a MWT battery hole filling paste, and a MWT battery.

[0094] Please refer to Example 1, the difference between Example 3 and Example 1 is that the raw materials of the glass frit of the MWT battery filling paste are different;

[0095] In this embodiment, the raw materials of the glass frit of the MWT battery hole filling paste are configured according to the following mass percentages:

[0096] P 2 o 5 60%, CuO8%, MgO8%, CaO10%, SiO 2 8% and K 2 O 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com