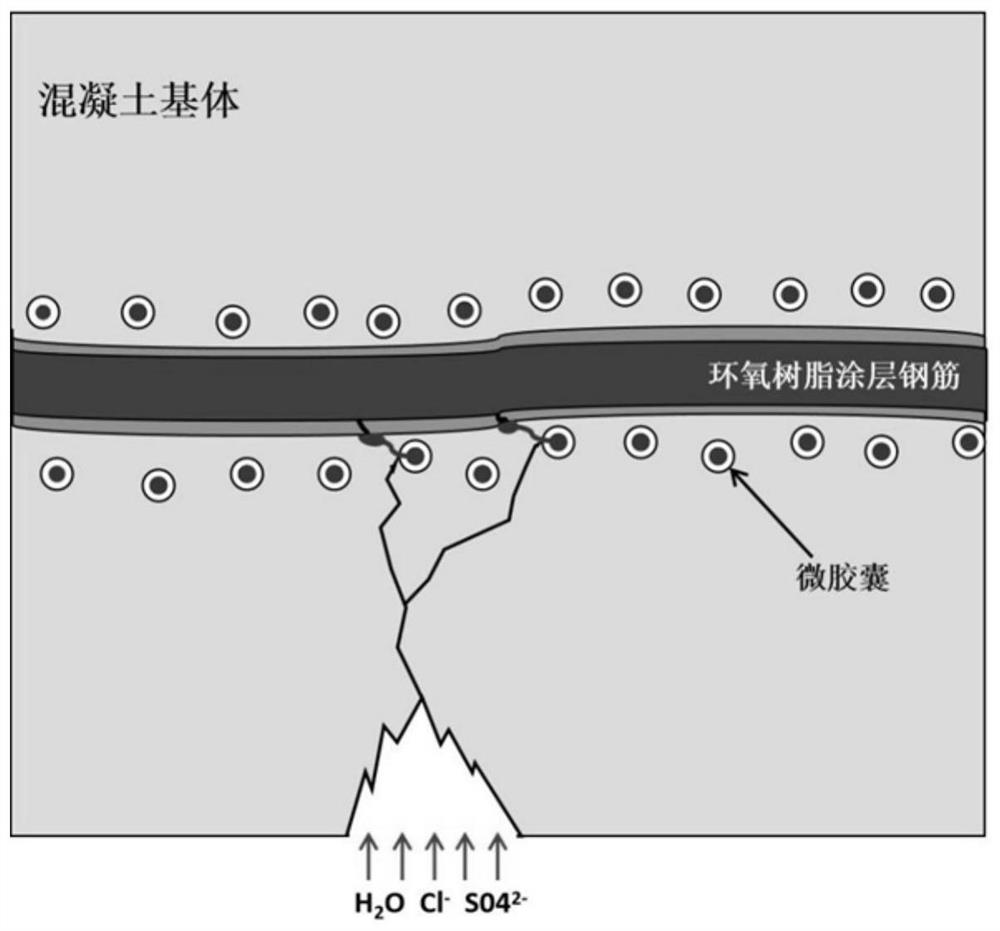

Concrete reinforcing steel bar corrosion prevention system based on microcapsule technology

A kind of microcapsule technology, concrete technology, applied in the field of anti-corrosion of steel bars, to achieve the effect of improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

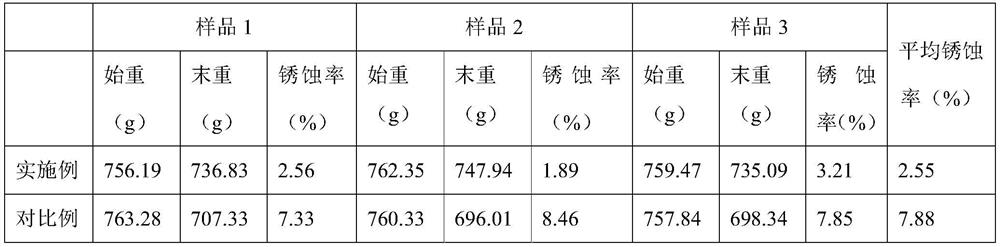

Embodiment 1

[0023] 1. Steel bar preparation

[0024] Take 6 epoxy-coated steel bars, model GHT RL335-20, each 300mm long, without any defects on the surface of the steel bars; use ultrasonic to clean the steel bars, dry them in a desiccator for 24 hours, take them out, and then use an analytical balance Weigh the initial weight of each steel bar (as shown in Table 1), and store it in a desiccator for later use.

[0025] 2. Preparation of Microcapsules

[0026] Weigh 3.00 g of sodium alginate solid, add it to 250 mL of deionized water, place it on a constant temperature magnetic stirrer, set the temperature at 60°C and stir, and after the sodium alginate solid is completely dissolved, a sodium alginate solution is obtained.

[0027] Add 0.200g of sodium dodecylbenzenesulfonate and 20.00g of epoxy resin to the sodium alginate solution respectively, continue stirring for 30min, and obtain an epoxy resin-sodium alginate mixed solution after cooling. The mass ratio of calcium alginate to epo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com