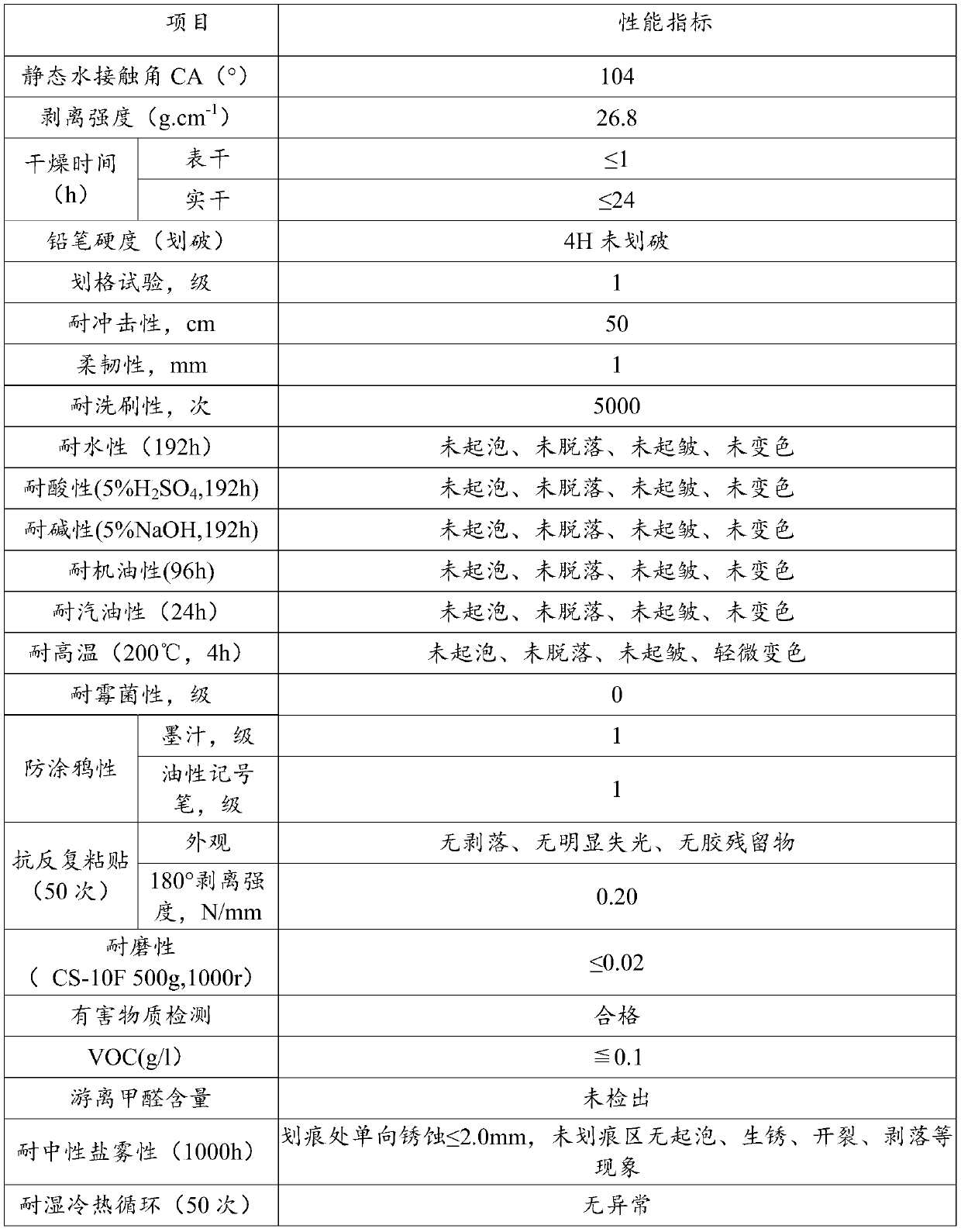

Stain-resistant high-temperature-resistant water-based coating and preparation method thereof

A water-based coating, high temperature resistant technology, applied in antifouling/underwater coatings, anti-corrosion coatings, fire-resistant coatings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. This embodiment provides a stain-resistant and high-temperature-resistant water-based paint in parts by weight. The raw materials of the stain-resistant and high-temperature-resistant water-based paint include the following components:

[0027] 50 parts of water-based fluorocarbon emulsion;

[0028] 20 parts of self-crosslinking silicone graft modified pure acrylic emulsion;

[0029] 24.5 parts of solvent;

[0030] 3 parts of filler;

[0031] 1 part of film-forming aid;

[0032] 0.5 parts of polyether polyurethane thickening rheological agent;

[0033] 0.5 parts of dispersant;

[0034] 0.2 parts of silicone defoamer;

[0035] 0.2 parts of anti-corrosion and anti-mold agent;

[0036] Thickener 0.1 part;

[0037] 0.3 parts of wetting agent;

[0038] 0.1 parts of ammonia water.

[0039] 2. The preparation method of the stain-resistant and high-temperature-resistant water-based paint includes the following steps: use a high-speed disperser to disperse and mix th...

Embodiment 2

[0045] 1. This embodiment provides a stain-resistant and high-temperature-resistant water-based paint in parts by weight. The raw materials of the stain-resistant and high-temperature-resistant water-based paint include the following components:

[0046] 35 parts of water-based fluorocarbon emulsion;

[0047] 15 parts of self-crosslinking silicone graft modified pure acrylic emulsion;

[0048] 24.5 parts of solvent;

[0049] 3 parts of filler;

[0050] 1 part of film-forming aid;

[0051] 0.5 parts of polyether polyurethane thickening rheological agent;

[0052] 0.5 parts of dispersant;

[0053] 0.2 parts of silicone defoamer;

[0054] 0.2 parts of anti-corrosion and anti-mold agent;

[0055] Thickener 0.1 part;

[0056] 0.3 parts of wetting agent;

[0057] 0.1 parts of ammonia water.

[0058] 2. The preparation method of the stain-resistant and high-temperature-resistant water-based paint includes the following steps: use a high-speed disperser to disperse and mix th...

Embodiment 3

[0064] 1. This embodiment provides a stain-resistant and high-temperature-resistant water-based paint in parts by weight. The raw materials of the stain-resistant and high-temperature-resistant water-based paint include the following components:

[0065] 30 parts of water-based fluorocarbon emulsion;

[0066] 20 parts of self-crosslinking silicone graft modified pure acrylic emulsion;

[0067] 15 parts of solvent;

[0068] 2 parts of filler;

[0069] 2 parts of film-forming aid;

[0070] 0.3 parts of polyether polyurethane thickening rheological agent;

[0071] 0.4 parts of dispersant;

[0072] 0.5 parts of silicone defoamer;

[0073] 0.6 parts of anti-corrosion and anti-mold agent;

[0074] 0.3 parts of thickener;

[0075] Wetting agent 0.1 part;

[0076] 0.2 parts of ammonia water.

[0077] 2. The preparation method of the stain-resistant and high-temperature-resistant water-based paint includes the following steps: use a high-speed disperser to disperse and mix the...

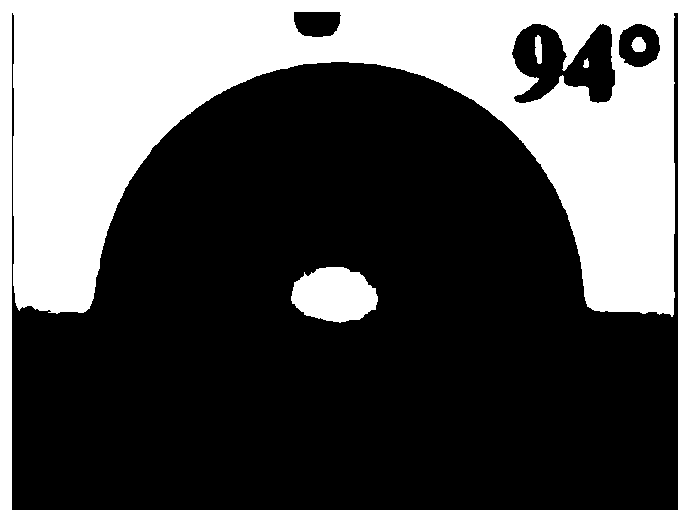

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com