PVDF/PETG composite and film for preparing same

A technology of composition and film, which is applied in the field of PVDF composition and its prepared film, can solve problems such as poor adhesion, achieve the effects of improved adhesion, reduced processing difficulty, and increased hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

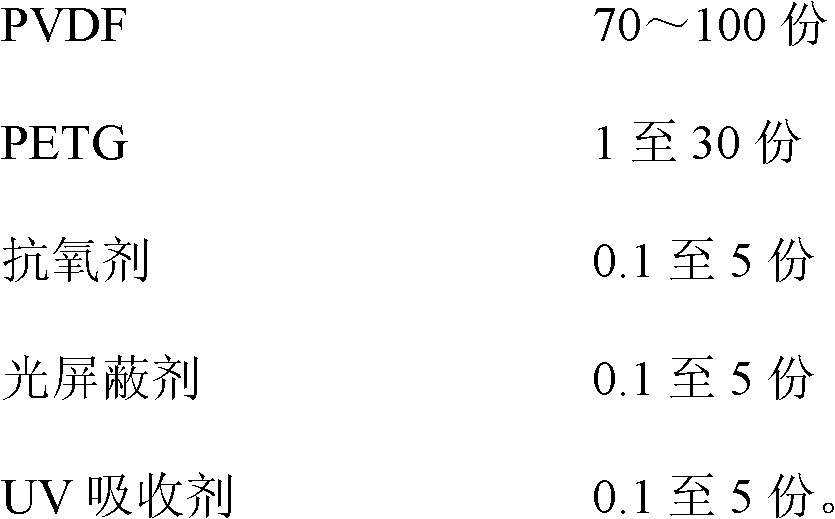

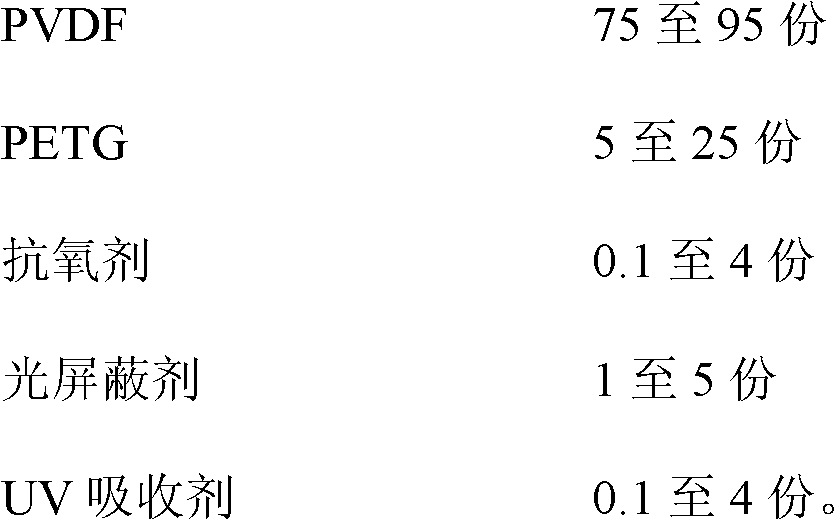

Method used

Image

Examples

Embodiment 1

[0032] The PVDF / PETG composition contains 75 parts of Kynar720 PVDF, 20 parts of SKYGREEN S2008 PETG, 2 parts of IRGANOX B215, 2 parts of R902+TiO 2 and 1 part Tinuvin R 326. The composition is cast by conventional methods to produce a film. The film had an elongation at break of 260% and had good adhesion. Moreover, the color difference value of the film is ΔE<2 after UV aging for 3000 hours in the UV aging box. For its outdoor application, this film has good adhesion, weather resistance and UV aging resistance.

Embodiment 2

[0034] The PVDF / PETG composition contains 80 parts of Kynar720 PVDF, 15 parts of SKYGREEN S2008 PETG, 1 part of IRGANOX B215, 3 parts of R902+TiO 2 and 1 part Tinuvin R 326. The composition is cast by conventional methods to produce a film. The film had an elongation at break of 223% and had good adhesion. Moreover, the color difference value of the film is ΔE<2 after UV aging for 3000 hours in the UV aging box. For its outdoor application, this film has good adhesion, weather resistance and UV aging resistance.

Embodiment 3

[0036] The PVDF / PETG composition contains 85 parts of Kynar720 PVDF, 10 parts of SKYGREEN S2008 PETG, 1 part of IRGANOX B215, 3 parts of R902+TiO 2 and 1 part Tinuvin R 326. The composition is cast by conventional methods to produce a film. The film had an elongation at break of 204% and had good adhesion. Moreover, the color difference value of the film is ΔE<2 after UV aging for 3000 hours in the UV aging box. For its outdoor application, this film has good adhesion, weather resistance and UV aging resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com