Bead core covering method and bead core covering device

A coating device and bead core technology, which is applied in the field of bead core coating and bead core coating devices, can solve the problems of sheet parts damage, wrinkles, and shortened length of side sheet parts, so as to prevent dimensional changes, Improve the effect of poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

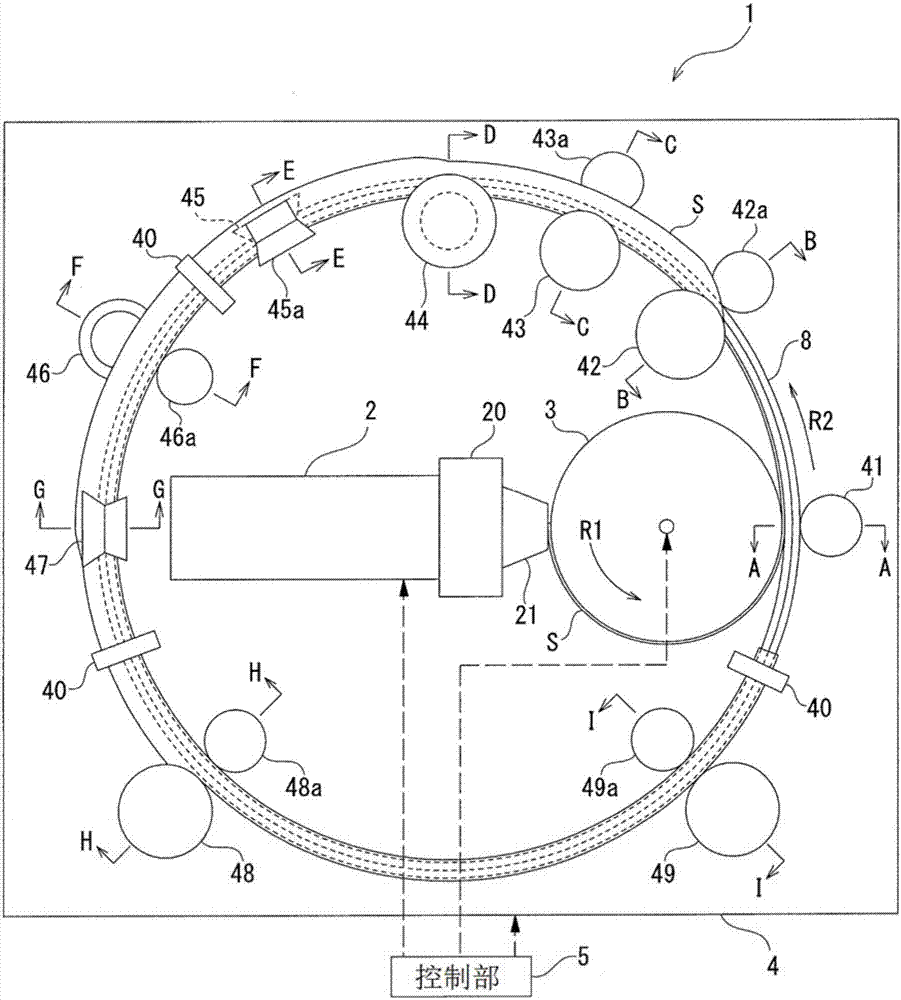

[0111] figure 1 It is a schematic diagram showing an example of the structure of the bead core covering device 1 . The bead core coating device 1 includes an extruder 2 , a rotary drum 3 , a covering device 4 , and a control unit 5 that controls the extruder 2 , the rotating drum 3 , and the covering device 4 .

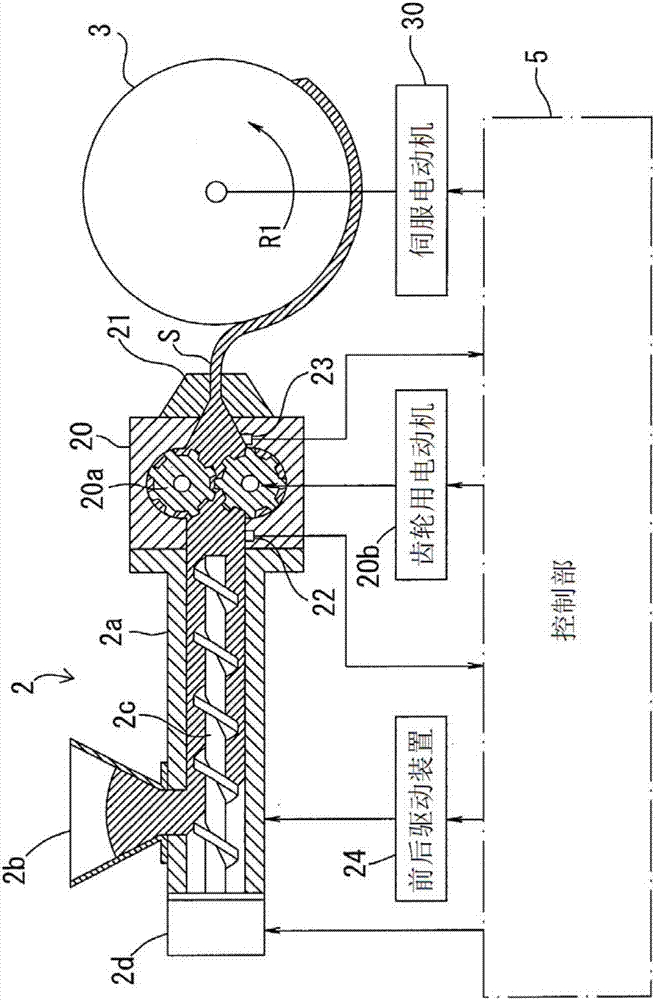

[0112] figure 2 It is a schematic diagram showing an example of the structure of the extruder 2 and the rotary drum 3 . The extruder 2 has: a cylindrical barrel 2a; a hopper 2b connected to a supply port of the barrel 2a; a screw 2c for kneading rubber and feeding it to the front end; and a screw motor 2d for rotationally driving the screw 2c. The rotation speed of the screw motor 2 d is controlled by the controller 5 as follows.

[0113] The front end side of the extruder 2 in the extrusion direction is connected to the gear pump 20 , and the front end side of the gear pump 20 is connected to the die 21 . The rubber material kneaded by the extruder 2 is supplied...

Embodiment approach

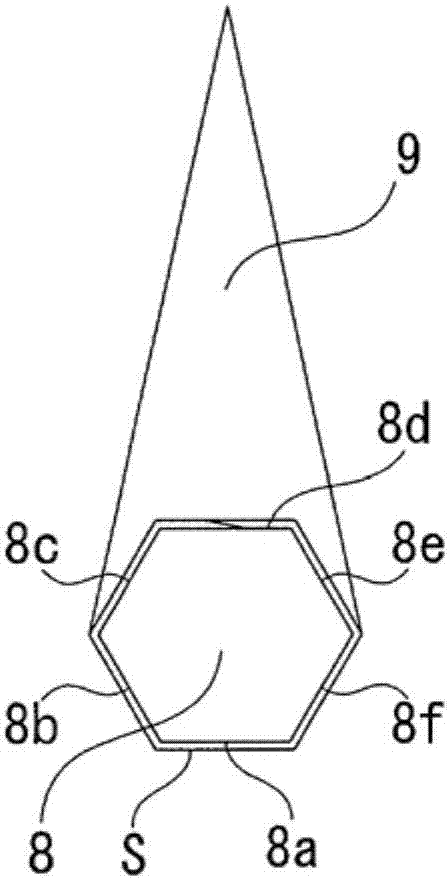

[0147] (1) In the first embodiment, the central portion in the width direction of the rubber sheet S wound on the outer peripheral surface of the rotary drum 3 is pasted on the inner periphery of the rotating bead core 8 from the front end. An example of the surface (lower surface 8a), but not limited thereto.

[0148] For example, if Figure 5 As shown, the rotating drum 3 may be arranged on the outer peripheral side of the bead core 8, and the center portion in the width direction of the rubber sheet S wound on the outer peripheral surface of the rotating drum 3 may be attached to the rotating bead core from the front end. 8 outer peripheral surface. According to this configuration, the structure of the equipment layout is simple, and it is also possible to easily cope with a dimensional change of the bead core.

[0149] In addition, the rotating drum 3 may be disposed on the side of the bead core 8, and the center portion in the width direction of the rubber sheet S wound...

no. 2 approach

[0152] Image 6 It is a schematic diagram showing an example of the structure of the bead core covering device 1 . The bead core coating device 1 includes an extruder 2 , a rotary drum 3 , a covering device 4 , and a control unit 5 that controls the extruder 2 , the rotating drum 3 , and the covering device 4 .

[0153] Figure 7 It is a figure which looked at the rotating drum 3 from the direction perpendicular|vertical to a rotation axis. The outer surface of the rotary drum 3 is formed with a circumferential groove 31 extending in the circumferential direction. The cross-sectional shape of the circumferential groove 31 in the axial direction of the rotary drum 3 is an inverted trapezoidal shape. The circumferential groove 31 includes a groove bottom surface 31 a and groove wall surfaces 31 b and 31 c extending from both sides of the groove bottom surface 31 a.

[0154] The cover device 4 supports the bead core 8 at a position downstream of the extruder 2 in the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com