Closestool bubble cleaning agent and preparation method thereof

A cleaning agent and bubble technology, applied in the field of cleaning agents, can solve the problems of running off, strong smell of bleach, cumbersome and other problems, and achieve the effect of good cleaning ability and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

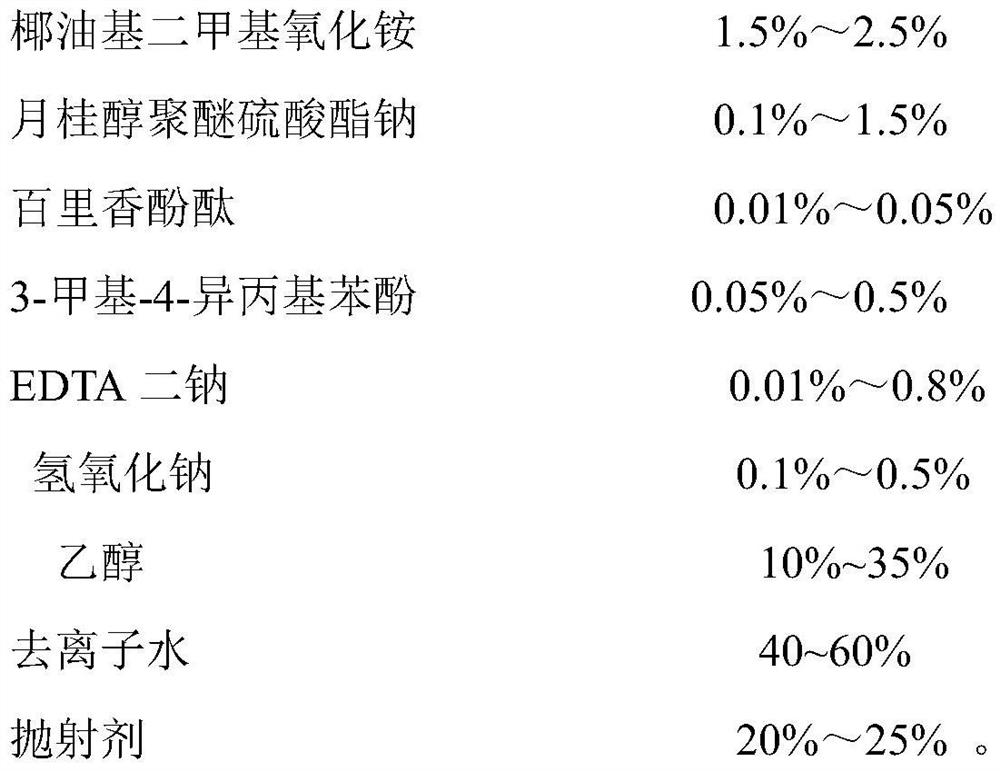

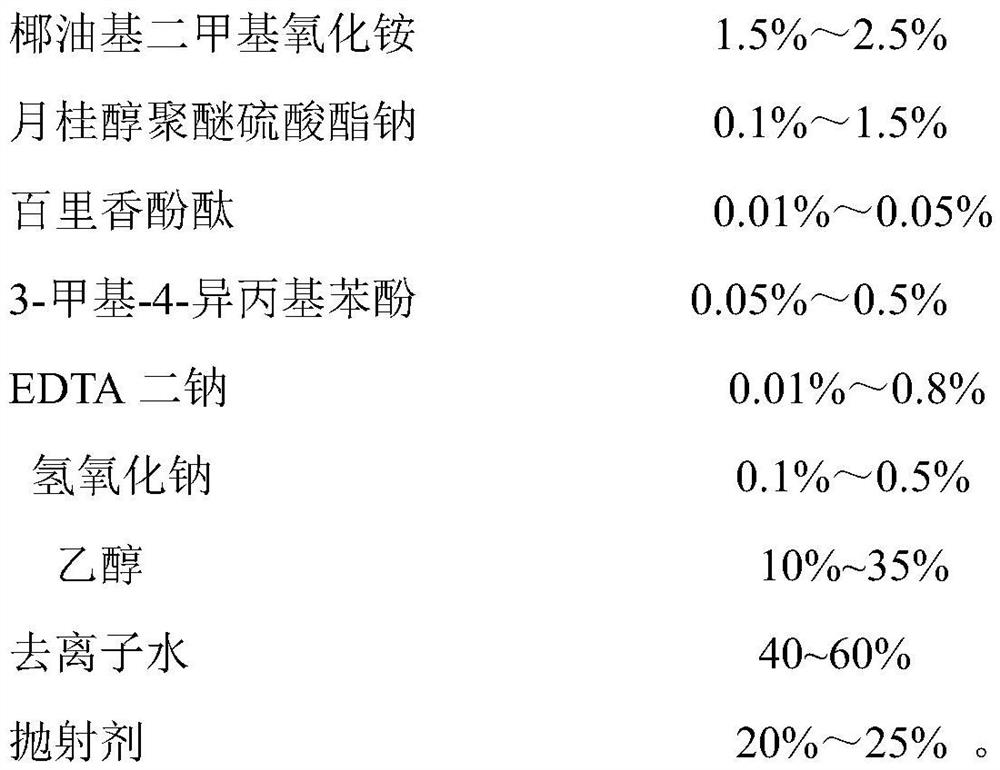

Embodiment 1

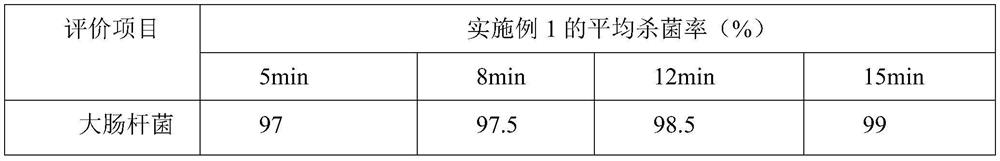

[0033] A kind of toilet bubble cleaner disclosed in the present embodiment comprises the following raw materials in percentage by weight, 1.5% of cocoyl dimethyl oxide, 0.1% of sodium laureth sulfate, 0.05% of thymolphthalein, 3-methyl- 0.5% 4-isopropylphenol, 0.8% disodium EDTA, 0.5% sodium hydroxide, 10% ethanol, 60% deionized water, 25% propellant.

[0034] Efficacy and effect of the preparation method of the above-mentioned toilet bubble cleaner: select bactericide to replace bleaching agent and can reduce the peculiar smell of cleaner; The principle of aerosol foaming makes the foam completely cover the dirt surface, which improves the poor adhesion of non-aerosol products; Thyme phenolphthalein is used as a reasonable color indicator to make the product have an intuitive cleaning indication function, and the foam spray It is blue, and when the foam turns white, it means that the cleaning has been completed, which is convenient and efficient to help consumers complete the...

Embodiment 2

[0050] A kind of toilet bubble cleaner disclosed in the present embodiment comprises the following raw materials in percentage by weight, cocoyl dimethyl ammonium oxide 1.5%, sodium laureth sulfate 1.5%, thymolphthalein 0.01%, 3-methyl - 0.05% of 4-isopropylphenol, 0.01% of disodium EDTA, 0.1% of sodium hydroxide, 10% of ethanol, 40% of deionized water, and 20% of propellant.

[0051] Efficacy and effect of the preparation method of the above-mentioned toilet bubble cleaner: select bactericides to replace bleaching agents to reduce the peculiar smell of cleaners; The principle of aerosol foaming makes the foam completely cover the dirt surface, improving the phenomenon of poor adhesion of non-aerosol products; choosing a reasonable color indicator to make the product have an intuitive cleaning indication function, and the foam is sprayed in blue When the foam turns white, it means that the cleaning has been completed, which is convenient and efficient to help consumers complet...

Embodiment 3

[0067] A kind of toilet bubble cleaner disclosed in the present embodiment comprises the following raw materials in percentage by weight, 2.3% of cocoyl dimethyl ammonium oxide, 1% of sodium laureth sulfate, 0.04% of thymolphthalein, 3-methyl - 0.4% of 4-isopropylphenol, 0.7% of disodium EDTA, 0.4% of sodium hydroxide, 20% of ethanol, 50% of deionized water, and 22% of propellant.

[0068] Efficacy and effect of the preparation method of the above-mentioned toilet bubble cleaner: select bactericides to replace bleaching agents to reduce the peculiar smell of cleaners; The principle of aerosol foaming makes the foam completely cover the dirt surface, improving the phenomenon of poor adhesion of non-aerosol products; choosing a reasonable color indicator to make the product have an intuitive cleaning indication function, and the foam is sprayed in blue When the foam turns white, it means that the cleaning has been completed, which is convenient and efficient to help consumers co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com