Preparation method of compound modified asphalt

A compound modified asphalt and compound modification technology, applied in the field of road engineering materials, can solve the problems of strict construction conditions, long maintenance time, water seepage on the road surface, etc., and achieve good economic benefits, excellent flame retardant and smoke suppression, and good road use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

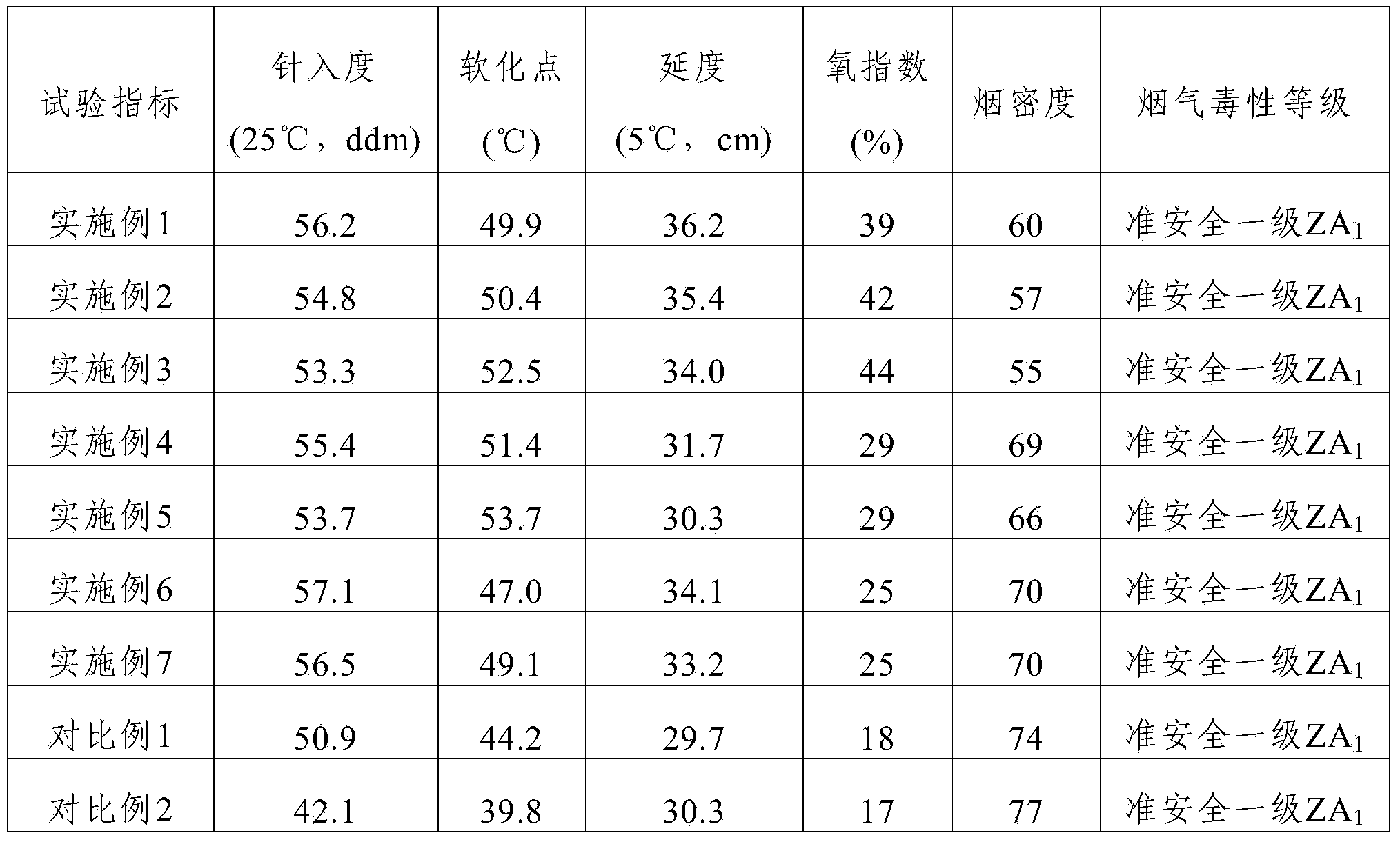

Examples

Embodiment 1

[0023] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0024] Step 1. Weigh various mineral powders in the following mass percentages: 59.4% of sillimanite powder, 39.2% of andalusite powder, and 1.4% of andesite powder; then mix the weighed various mineral powders evenly to obtain a mixed powder; The particle size of sillimanite powder, andalusite powder and andesite powder is 37μm~74μm;

[0025] Step 2, adding the dispersant to the mixed powder described in step 1 and mixing uniformly to obtain the mixed powder after dispersion treatment; the dispersant is the isopropanol solution of stearamide, and the isopropanol of the stearamide is The mass ratio of rigid amide and isopropanol in the solution is 1: 1.2; the addition of the dispersant is 0.5% of the mixed powder mass;

[0026] Step 3, adding the surfactant to the mixed powder after the dispersion treatment described in step 2 and mixing evenly to obtain the mix...

Embodiment 2

[0030] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0031] Step 1. Weigh various mineral powders in the following mass percentages: 23% of sillimanite powder, 76.1% of andalusite powder, and 0.9% of andesite powder; then mix the weighed various mineral powders evenly to obtain a mixed powder; The particle size of sillimanite powder, andalusite powder and andesite powder is 61μm~165μm;

[0032] Step 2, adding the dispersant to the mixed powder described in step 1 and mixing uniformly to obtain the mixed powder after dispersion treatment; the dispersant is the isopropanol solution of stearamide, and the isopropanol of the stearamide is The mass ratio of rigid amide and isopropanol in the solution is 1:1; the addition of the dispersant is 0.8% of the mixed powder mass;

[0033] Step 3, adding the surfactant to the mixed powder after the dispersion treatment described in step 2 and mixing evenly to obtain the mixed p...

Embodiment 3

[0037] The preparation method of the present embodiment composite modified asphalt comprises the following steps:

[0038] Step 1. Weigh various mineral powders in the following mass percentages: 43% of sillimanite powder, 56% of andalusite powder, and 1% of andesite powder; then mix the weighed various mineral powders evenly to obtain a mixed powder; The particle size of sillimanite powder, andalusite powder and andesite powder is 150μm~212μm;

[0039] Step 2, adding the dispersant to the mixed powder described in step 1 and mixing uniformly to obtain the mixed powder after dispersion treatment; the dispersant is the isopropanol solution of stearamide, and the isopropanol solution of the stearamide The mass ratio of rigid amide and isopropanol in the solution is 1: 1.5; the addition of the dispersant is 0.6% of the mixed powder mass;

[0040]Step 3, adding the surfactant to the mixed powder after the dispersion treatment described in step 2 and mixing evenly to obtain the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com