Anodized aluminum foil and preparation method thereof

A technology of anodized aluminum foil and aluminum layer, which is applied in printing, ink transfer from original manuscripts, and technology for producing decorative surface effects. It can solve the problems of poor adhesion between the aluminum layer and the imaging layer, and achieve poor adhesion, Strong adhesion, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

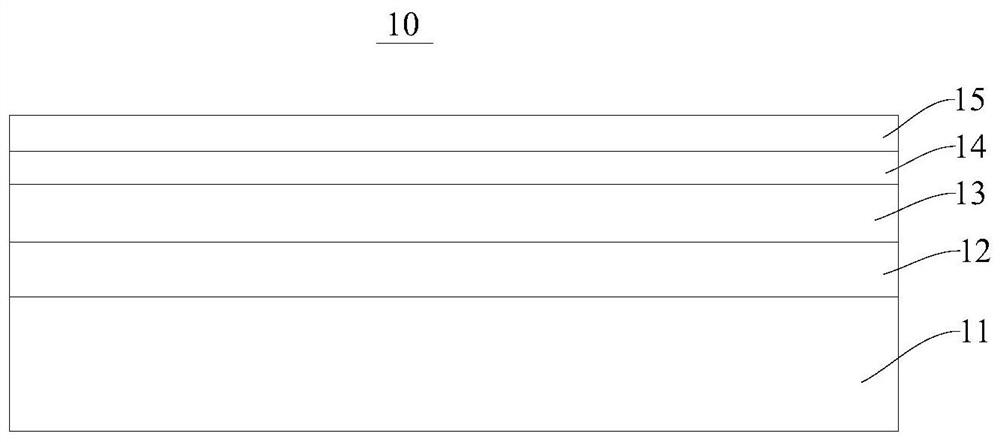

[0029] In a second aspect, an embodiment of the present application further provides a method for preparing the anodized aluminum foil 10 according to the embodiment of the first aspect, including:

[0030] A release layer is formed on the surface of the base film 11; a mixture of the first resin and dye is coated on the surface of the release layer, and a laser pattern is molded to form an imaging layer 13; The raw material forms the protective layer 14 ; the surface of the protective layer 14 is plated with aluminum to form the aluminum layer 15 .

[0031] In the preparation method of the anodized aluminum foil 10 according to the embodiment of the present application, when the surface of the imaging layer 13 is coated with a raw material containing the second resin, the second resin and the first resin belong to the same type of resin, so that the adhesion between the protective layer 14 and the imaging layer 13 is improved. better. The surface of the protective layer 14 i...

Embodiment 1

[0034] This embodiment provides an anodized aluminum foil 10 , which includes a PET film, a release layer 12 , an imaging layer 13 , a protective layer 14 and an aluminum layer 15 that are stacked in sequence. The imaging layer 13 contains polymethyl methacrylate and dye, and the mass of the dye is 8% of the mass of polymethyl methacrylate. The protective layer 14 is methyl methacrylate-butyl methacrylate-butyl acrylate-methacrylic acid copolymer.

[0035] The preparation method of the anodized aluminum foil 10 of this embodiment includes:

[0036] A release layer 12 is formed on the surface of the base film 11; a mixture of polymethyl methacrylate and dye is coated on the surface of the release layer 12, and a laser pattern is molded to form an imaging layer 13; the surface of the imaging layer 13 is coated The protective layer 14 is formed by methyl methacrylate-butyl methacrylate-butyl acrylate-methacrylic acid copolymer; the aluminum layer 15 is formed by plating aluminum...

Embodiment 2

[0038] This embodiment provides an anodized aluminum foil 10 , which includes a PET film, a release layer 12 , an imaging layer 13 , a protective layer 14 and an aluminum layer 15 that are stacked in sequence. The imaging layer 13 contains polymethyl methacrylate and a dye, and the mass of the dye is 10% of the mass of the polymethyl methacrylate. The protective layer 14 is methyl methacrylate-butyl methacrylate-butyl acrylate-methacrylic acid copolymer.

[0039] The preparation method of the anodized aluminum foil 10 of this embodiment includes:

[0040] A release layer 12 is formed on the surface of the base film 11; a mixture of polymethyl methacrylate and dye is coated on the surface of the release layer 12, and a laser pattern is molded to form an imaging layer 13; the surface of the imaging layer 13 is coated The protective layer 14 is formed by methyl methacrylate-butyl methacrylate-butyl acrylate-methacrylic acid copolymer; the aluminum layer 15 is formed by plating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com