Cellulose-ester film, manufacturing method therefor, and polarizing plate

A technology of cellulose ester film and manufacturing method, which can be applied to polarizing elements, instruments, optical elements, etc., can solve the problems of reduced ductility of adhesive, increase in size, and no implied structure, etc., and achieve the effect of excellent adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

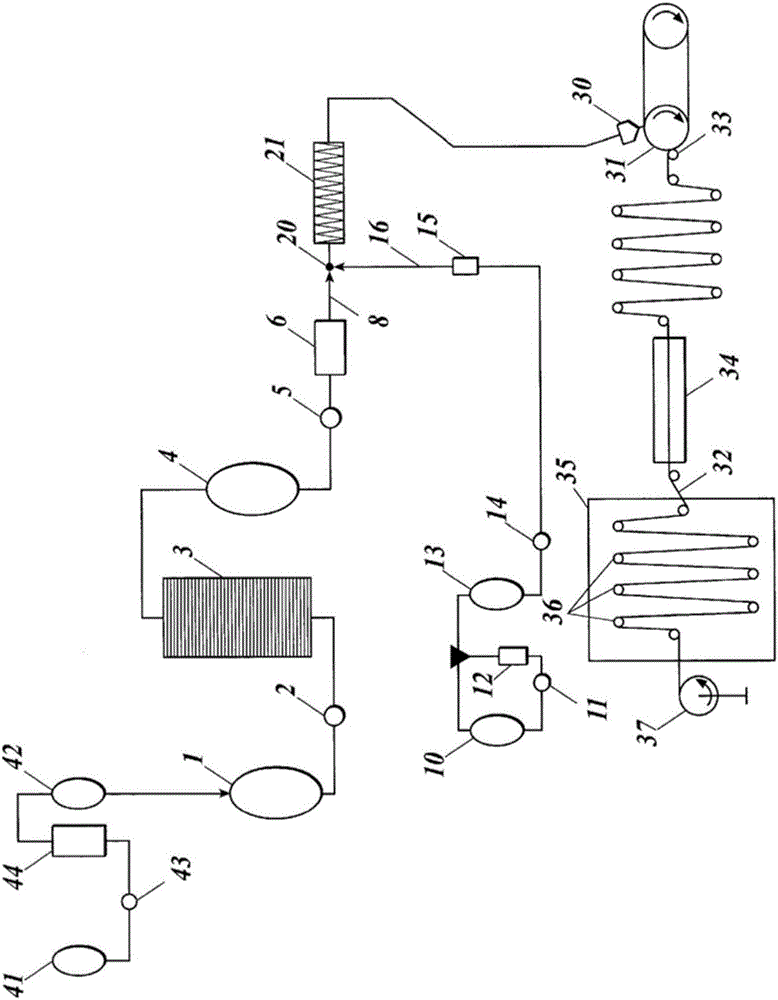

preparation example Construction

[0082] The film thickness of the above-mentioned cellulose ester film is within a range of 20 to 38 μm, which is a preferable film thickness range from the viewpoint of production of a thin film polarizing plate and contributing to thinning of a liquid crystal display device using the same.

[0083] From the viewpoint of optimizing the visibility of VA-mode liquid crystal display devices, the retardation value Re in the in-plane direction of the above-mentioned cellulose ester film is in the range of 45 to 60 nm, and the retardation value Rth in the film thickness direction is 110 to 140 nm. When it is within the range, it is a preferable range.

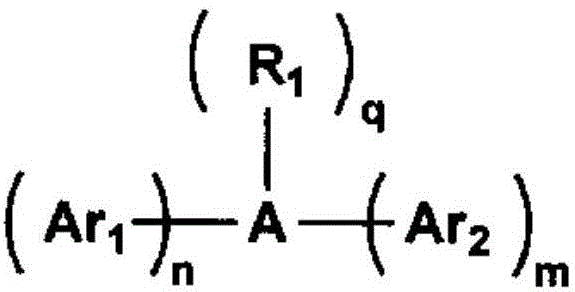

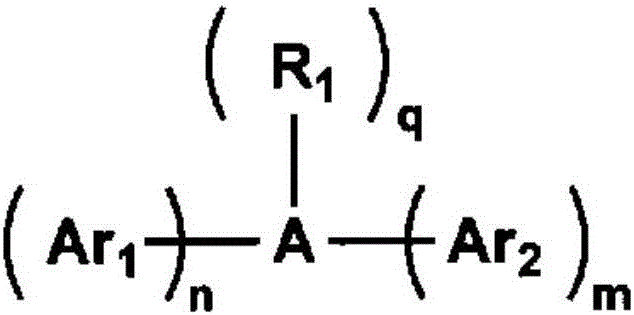

[0084] In addition, the above-mentioned retardation increasing agent is a nitrogen-containing heterocyclic compound containing a pyrazole ring or an imidazole ring having a structure represented by the above-mentioned general formula (A). Since the transmittance is adjusted to 80% or more, it is a preferable compound. Furthermore, t...

Synthetic example

[0210]

[0211] An example of synthesis of sugar esters that can be preferably used in the present invention is shown below.

[0212] [chemical formula 9]

[0213]

[0214] 34.2g (0.1 moles) of sucrose, 180.8g (0.8 moles) of benzoic anhydride, and 379.7g (4.8 moles) of pyridine are respectively loaded into the four-necked Erlenmeyer flask with stirring device, reflux cooler, thermometer and nitrogen inlet pipe, While bubbling nitrogen gas from a nitrogen gas introduction tube with stirring, it heated up, and esterification reaction was performed at 70 degreeC for 5 hours. Next, depressurize the Erlenmeyer flask to 4×10 2 Below Pa, after distilling off excess pyridine at 60° C., the inside of the Erlenmeyer flask was decompressed to below 1.3×10 Pa, and the temperature was raised to 120° C. to distill off most of benzoic anhydride and generated benzoic acid. Then, 1 L of toluene and 300 g of a 0.5 mass % sodium carbonate aqueous solution were added, and after stirring at...

Embodiment 1

[0521] Table 1 shows the contents of cellulose esters used in Examples. In the table, DAC means: diacetyl cellulose, CAP means: cellulose acetate propionate, and TAC means: triacetyl cellulose.

[0522] [Table 1]

[0523]

[0524]

[0525] [Preparation of Cellulose Ester Film 101]

[0526] The cellulose ester film 101 was prepared according to the method described below.

[0527] (Preparation of fine particle dispersion diluent)

[0528] After stirring and mixing 10 parts by mass of AEROSIL R812 (manufactured by Japan Aerosil Co., Ltd., primary average particle size: 7 nm, apparent specific gravity 50 g / L) and 90 parts by mass of ethanol with a dissolving bar for 30 minutes, use a Manton high-pressure disperser -Gaulin disperses to prepare a fine particle dispersion.

[0529] 88 parts by mass of dichloromethane was added to the obtained fine particle dispersion liquid while being stirred, and stirred and mixed with a dissolving bar for 30 minutes to dilute. The obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com