Energy storing assembly

A component and energy storage technology, applied in electrical components, structural parts, electrolytic capacitors, etc., can solve the problems of insufficient battery plate adhesion, large electrode impedance, poor battery performance, etc., to improve poor adhesion, reduce Plate resistance value, the effect of excellent battery characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

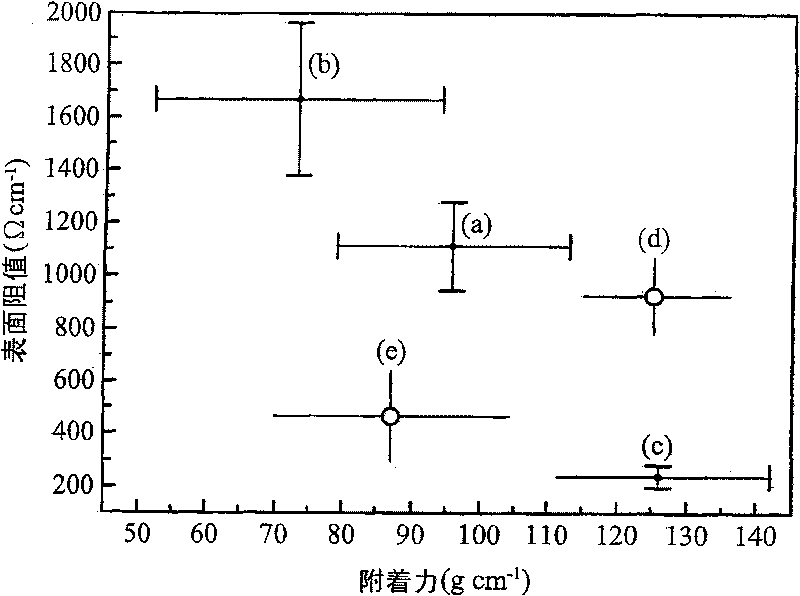

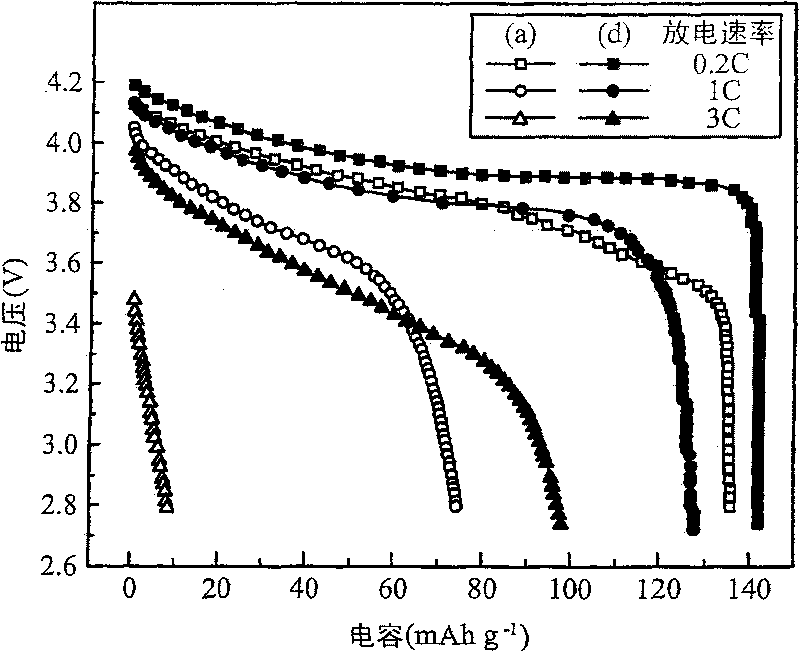

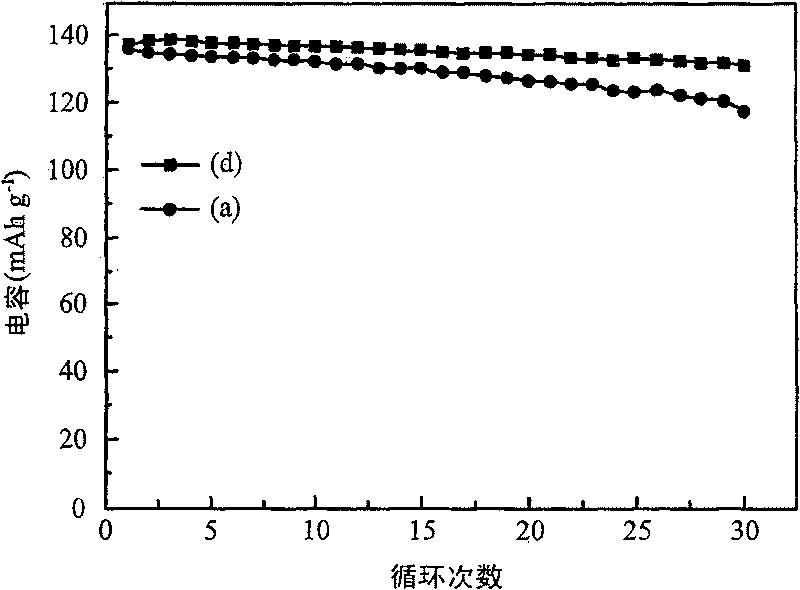

[0028] [Example 1] Preparation of positive electrode structure containing polyacrylonitrile aqueous adhesive

[0029] First, 91 parts by weight of LiCoO 2 , 6 parts by weight of polyacrylonitrile (n=1,300) and 4 parts by weight of acetylene black (conductive powder) are dispersed in N-methylpyrrolidone (NMP) to form a slurry. After that, the slurry was coated on an aluminum foil. After drying, it is compressed and cut to prepare a positive electrode.

[0030] Mix 2 parts by volume of propylene carbonate (PC for short), 3 parts by volume of ethylene carbonate (EC for short) and 5 parts by volume of diethyl carbonate (DEC for short) as the organic electrolyte of the electrolyte solution. solvent. The lithium salt of this solution is LiPF 6 , the concentration is 1M. Next, the anode and the lithium cathode are separated by a polypropylene separator (PP), and the above-mentioned electrolyte solution is added to the accommodating area between the anode and the cathode. After ...

Embodiment 2

[0031] [Example 2] Preparation of positive electrode structure containing styrene-butadiene rubber (SBR) and polyacrylonitrile aqueous adhesive

[0032] First, 91 parts by weight of LiCoO 2 , 6 parts by weight of a mixture of styrene-butadiene rubber and polyacrylonitrile (n=1,300) (weight ratio of styrene-butadiene rubber:polyacrylonitrile=3:7) and 4 parts by weight of acetylene black ( conductive powder) is dispersed in N-methylpyrrolidone (NMP) to form a slurry. After that, the slurry was coated on an aluminum foil. After drying, it is compressed and cut to prepare a positive electrode.

[0033] 2 parts by volume of propylene carbonate (PC), 3 parts by volume of ethylene carbonate (EC), and 5 parts by volume of diethyl carbonate (DEC) were mixed as the organic solvent of the electrolyte solution. The lithium salt of this solution is LiPF 6 , the concentration is 1M. Next, the anode and the lithium cathode are separated by a polypropylene separator (PP), and the above-m...

Embodiment 3

[0034] [Example 3] Preparation of positive electrode structure containing polyacrylate and polyacrylonitrile aqueous adhesive

[0035] First, 91 parts by weight of LiCoO 2 , 6 parts by weight of polyacrylate (X is butyl, n=1,500) and polyacrylonitrile (n=1,300) mixture (weight ratio of polybutylacrylate: polyacrylonitrile=3:7) and 4 parts by weight of Acetylene black (conductive powder) was dispersed in N-methylpyrrolidone (NMP) to form a slurry. After that, the slurry was coated on an aluminum foil. After drying, it is compressed and cut to prepare a positive electrode.

[0036] 2 parts by volume of propylene carbonate (PC), 3 parts by volume of ethylene carbonate (EC), and 5 parts by volume of diethyl carbonate (DEC) were mixed as the organic solvent of the electrolyte solution. The lithium salt of this solution is LiPF 6 , the concentration is 1M. Next, the anode and the lithium cathode are separated by a polypropylene separator (PP), and the above-mentioned electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com