Bactericidal/disinfectant peracetic composition

A technology of peracetic acid and phosphate, used in the field of decontamination, can solve the problems of skin itching, weakened unpleasant odor, unpleasant odor, and itchy skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

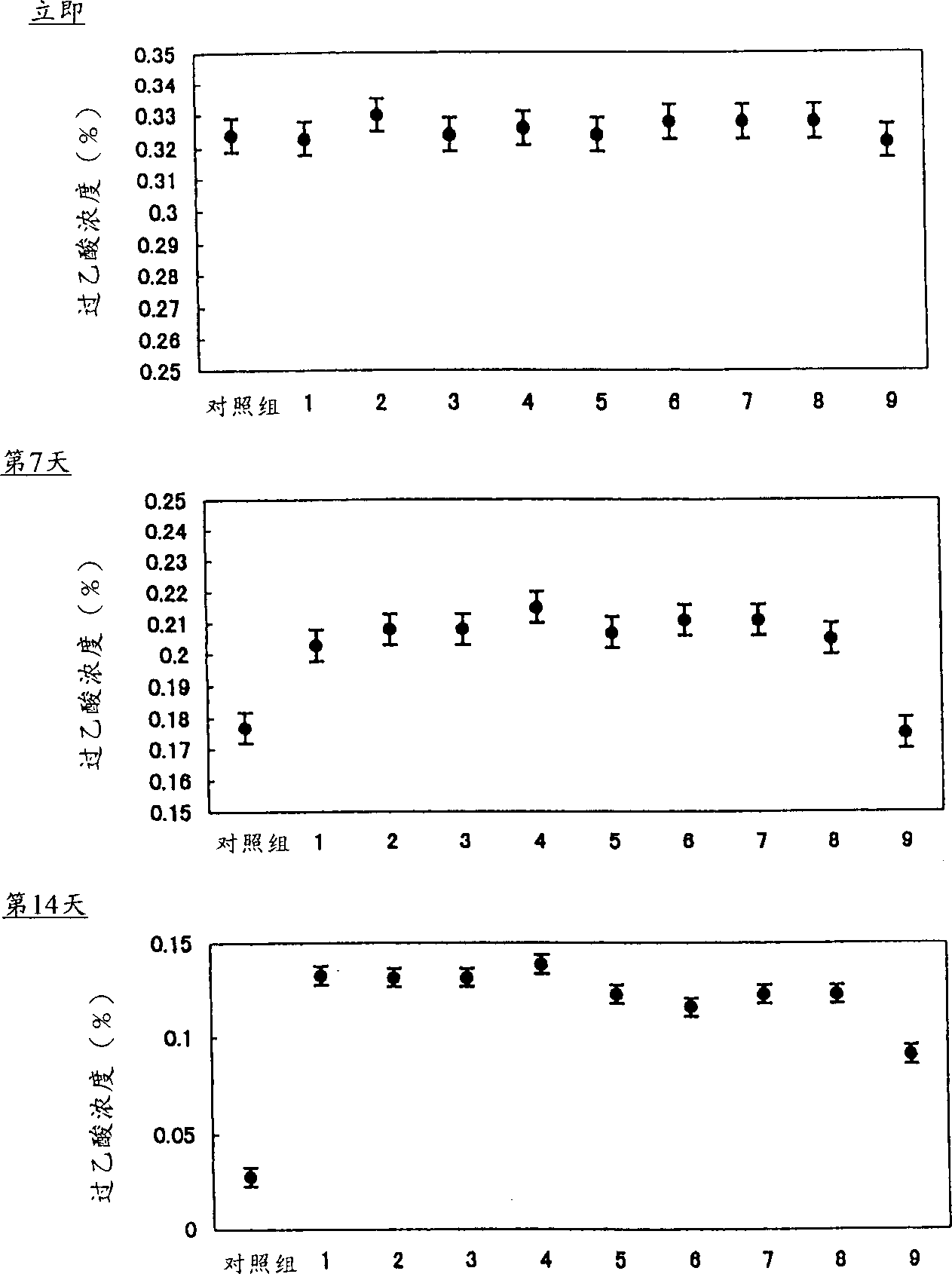

[0074] A 0.33% aqueous solution of peracetic acid (pH 4.0) containing 1% sodium thiosulfate and 0.05% of one of the nonionic surfactants listed in Table 1 was prepared. The aqueous peracetic acid solution was placed in a glass beaker and stored at room temperature (25°C) for 2 weeks. Samples of the aqueous peracetic acid solutions were withdrawn periodically during storage, and the concentrations of peracetic acid in the sample solutions were measured according to the method described by Sully, B.D. and Williams, P.L., Analytical 1962;87:653-657.

[0075] Table 1 nonionic surface active additive 1.Newdet PE85 (polyoxyethylene / polyoxypropylene block polymer, Sanyo Chemical Industries Co., Ltd.) 2.Ionet T-60C (polyoxyethylene sorbitol fatty acid, Sanyo Chemical Industries Co, Ltd.) 3 Emulmin 70 (polyoxyethylene alkyl ether, Sanyo Chemical Industries Co, Ltd.) 4. Nonipole 100 (polyoxyethylene nonylphenyl ether, Sanyo Chemical Industries Co., Ltd.) 5 . Noygen ET-190 (polyethylene...

Embodiment 2

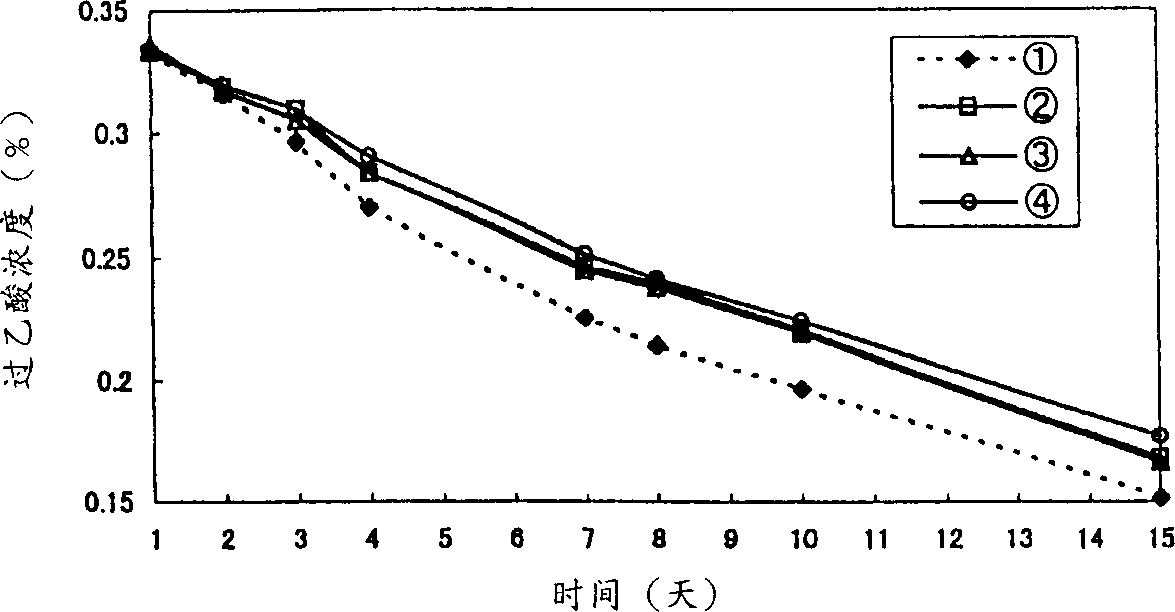

[0080] Dipotassium hydrogen phosphate was added to the 0.3% peracetic acid solution to make the final concentration 0.296% (pH3.5). The prepared solution was divided into 6 parts, and each part was added with surfactant, reactant and mixture thereof (① to ⑥ in Table 2) to form a test solution. The test solutions were stored at room temperature (25°C). The concentration of peracetic acid in the test solution and the effect of the test solution on bacterial spores were measured every day.

[0081] Table 2 Additives

[0082] ① No additives (comparison 1)

[0083] ② Newdet PE85 0.05%

[0084] ③Newpole PE64 0.05%

[0085] ④Nonipole 100 0.05%

[0086] ⑤Newdet PE85 0.05%+EDTA2Na 0.025%

[0087] +EDTA4Na 0.025%

[0088] ⑥EDTA2Na 0.025%+EDTA4Na 0.025% (comparison 2)

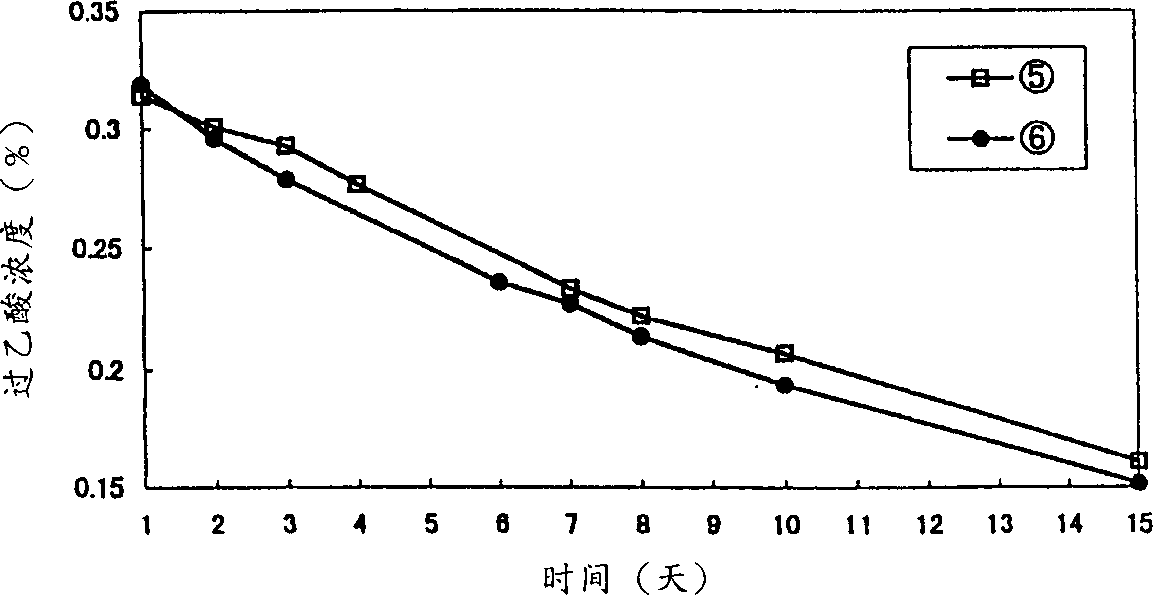

[0089] Figures 2 and 3 show the results of measurements of the concentration of peracetic acid in each sample.

[0090] As shown in Figures 2 and 3, after 10 days of storage at room temperatur...

Embodiment 3

[0097] The following two formulations were prepared:

[0098] first reactant

[0099] Peracetic acid 6%

[0101] Acetic acid 32%

[0102] Phosphate type stabilizer 0.2%

[0103] water balance

[0104] Second reactant

[0105] Dipotassium Phosphate 6%

[0106] Newdet PE85 (Sanyo Chemical Industries Co., Ltd.) 1%

[0107] EDTA2Na 0.5%

[0108] EDTA4Na 0.5%

[0109] water balance

[0110] The first and second reagents were mixed in equal amounts and diluted 10 times by volume to make a test solution. The solution contained about 0.33% peracetic acid.

[0111] The test solution was used to sterilize and disinfect endoscopes using a newly developed automatic endoscope cleaner for this purpose.

[0112] The biopsy forceps (Olympus GIF type XQ240; Olympus Optical Industries, Co., Ltd.) of the flexible endoscope used in the upper gastrointestinal tract were supplied by an automatic endoscope cleaner (Olympus EW-30; Olympus Optical Industries, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com