Preparation method for gelatin/hydroxyapatite composite coating

A hydroxyapatite and composite coating technology, applied in coatings, pharmaceutical formulations, pharmaceutical science and other directions, can solve problems such as poor affinity, and achieve the effect of improving poor affinity and increasing interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Add 1 g of gelatin particles (about 57306 molecular weight) into deionized water to swell for 2 hours, and then heat to 50°C to form a 2wt% gelatin solution. After the gelatin is completely dissolved, add 25mL of 0.2M CaCl 2 Add the solution into the gelatin solution, and slowly add 0.12M NaH 2 PO 4 The solution was stirred at 50° C. for 4 h after the dropwise addition, and aged for 1 h to obtain a mixed gelatin solution.

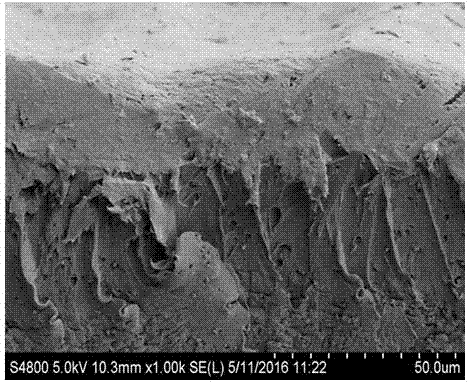

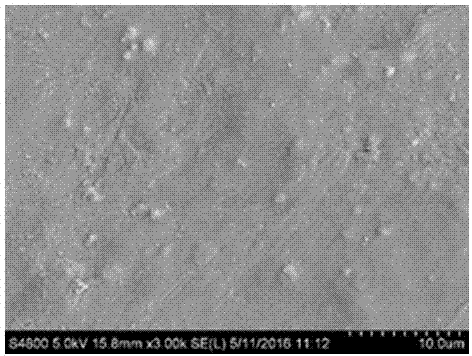

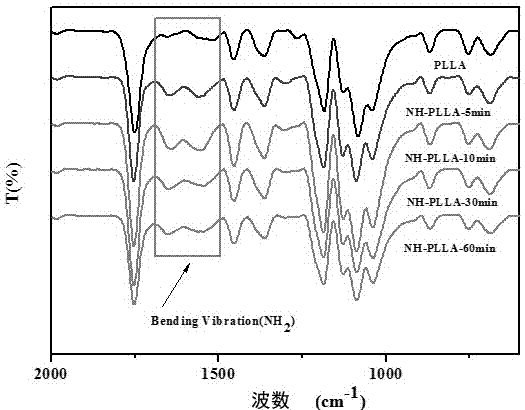

[0041] Soak the PLLA / β-TCP scaffold sheet cut into about 10mm*10mm in 20mL ethanol:water (v / v)=1:1 for 2h, then rinse with plenty of water, soak the cleaned sheet in 1,6 -Hexamethylenediamine / isopropanol=2.4g / 20mL, react at 45°C for 10min, deionize and wash for 12h, and vacuum dry for 24h to obtain aminated flakes, which are then soaked in 10mL of 1wt% 1,5-pentanediene Aldehyde solution, deionized cleaning 12h, vacuum drying to obtain flakes.

[0042] Prepare a mixed gelatin solution of 3 mg / mL, soak the above sheet in the mixed gelatin solution f...

Embodiment 2

[0049] Add 1 g of gelatin particles (about 49317 molecular weight) into deionized water to swell for 2 hours, and then heat to 50°C to form a 2wt% gelatin solution. After the gelatin is completely dissolved, add 25mL of 0.2M CaCl 2 Add the solution into the gelatin solution, and slowly add 0.12M NaH 2 PO 4 The solution was stirred at 50° C. for 4 h after the dropwise addition, and aged for 1 h to obtain a mixed gelatin solution.

[0050] Soak the PLLA / β-TCP scaffold sheet cut into about 10mm*10mm in 20mL ethanol:water (v / v)=1:1 for 2h, then rinse with plenty of water, soak the cleaned sheet in 1,6 -Hexamethylenediamine / isopropanol=2.4g / 20mL, react at 45°C for 10min, deionize and wash for 12h, and vacuum dry for 24h to obtain aminated flakes, which are then soaked in 10mL of 1wt% 1,5-pentanediene Aldehyde solution, deionized cleaning 12h, vacuum drying to obtain flakes.

[0051] The surface contact angle of PLLA / β-TCP scaffold decreased from 82.2° before modification to 50.4...

Embodiment 3

[0054] Add 1 g of gelatin particles (about 38379 molecular weight) into deionized water to swell for 2 hours, then heat to 50°C to form a 2wt% gelatin solution. After the gelatin is completely dissolved, add 25 mL of 0.2M CaCl 2 Add the solution into the gelatin solution, and slowly add 0.12M NaH 2 PO 4 The solution was stirred at 50° C. for 4 h after the dropwise addition, and aged for 1 h to obtain a mixed gelatin solution.

[0055] Soak the PLLA / β-TCP scaffold sheet cut into about 10mm*10mm in 20mL ethanol:water (v / v)=1:1 for 2h, then rinse with plenty of water, soak the cleaned sheet in 1,6 -Hexamethylenediamine / isopropanol=2.4g / 20mL, react at 45°C for 10min, deionize and wash for 12h, and vacuum dry for 24h to obtain aminated flakes, which are then soaked in 10mL of 1wt% 1,5-pentanediene Aldehyde solution, deionized cleaning 12h, vacuum drying to obtain flakes.

[0056] The surface contact angle of PLLA / β-TCP scaffold decreased from 82.2° before modification to 51.8° a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com