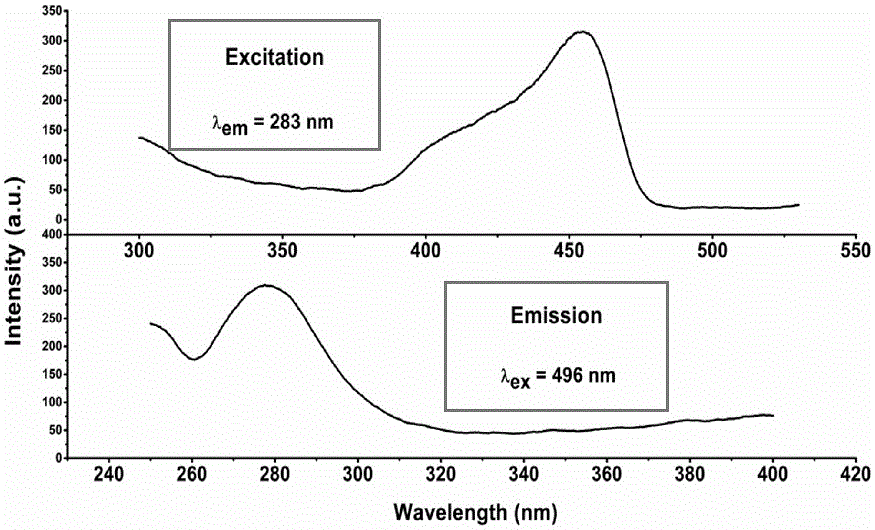

Phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, and preparation method and application thereof

A technology of metaphosphate and rare earth ions, applied in luminescent materials, applications, chemical instruments and methods, etc., can solve problems such as hidden safety hazards for operators, inability to sterilize applications, etc., achieve low price, sterilization or inhibit bacterial growth, and reduce sterilization. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh yttrium oxide, praseodymium oxide and ammonium dihydrogen phosphate according to the molar ratio of each element yttrium:praseodymium:phosphorus=0.95:0.05:3, mix and grind until pulverized, then burn at 900°C for 3h, cool down to room temperature, take out, and grind , to obtain powdered yttrium metaphosphate-based rare earth visible-ultraviolet up-conversion luminescent material.

Embodiment 2

[0036] Weigh yttrium oxide, praseodymium oxide and ammonium dihydrogen phosphate according to the molar ratio of each element yttrium:praseodymium:phosphorus=0.95:0.05:3, mix and grind until pulverized, then burn at 950°C for 2.5h, drop to room temperature, take out, Grinding to obtain powdery yttrium metaphosphate-based rare earth visible-ultraviolet up-conversion luminescent material.

Embodiment 3

[0038] Weigh yttrium oxide, praseodymium oxide and ammonium dihydrogen phosphate according to the molar ratio of each element yttrium:praseodymium:phosphorus=0.95:0.05:3, mix and grind until pulverized, then burn at 850°C for 4h, cool down to room temperature, take out, and grind , to obtain powdered yttrium metaphosphate-based rare earth visible-ultraviolet up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com