Patents

Literature

96results about How to "Reduce sterilization costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for air conditioner sterilization and air conditioner

ActiveCN109297101AEasy to operateImprove experienceMechanical apparatusLighting and heating apparatusEngineeringAir temperature

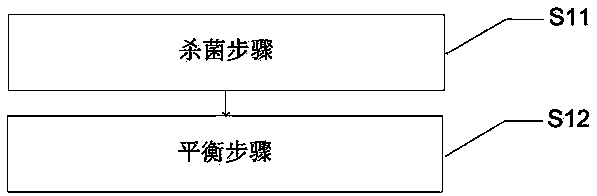

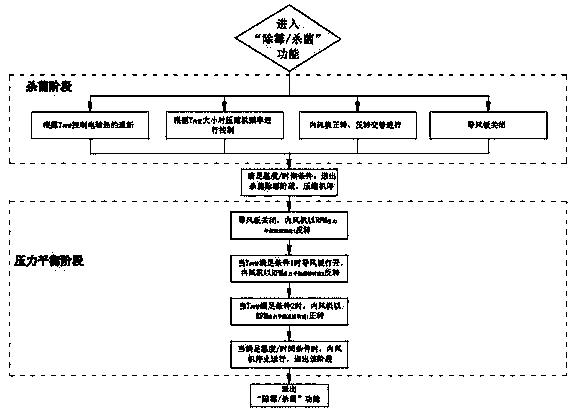

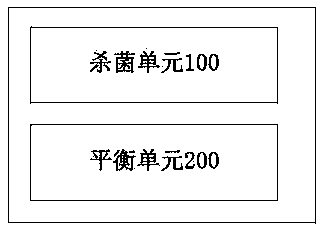

The invention provides a method and a system for air conditioner sterilization and an air conditioner. The air conditioner sterilization method sequentially comprises a sterilization step and a balance step; the sterilization step comprises the steps that the air conditioner is operated in a heating mode, so that the air temperature inside the air conditioner is higher than a first temperature, and then the interior of the air conditioner is sterilized; and the balance step is used for closing the an air conditioner compressor and controlling an air guide plate and / or an inner fan, so that thetemperature and / or the pressure inside the air conditioner are reduced. According to the method, the structure of the air conditioner does not need to be changed, and an indoor unit of the air conditioner can be mildew removed and sterilized.

Owner:GREE ELECTRIC APPLIANCES CHONGQING +1

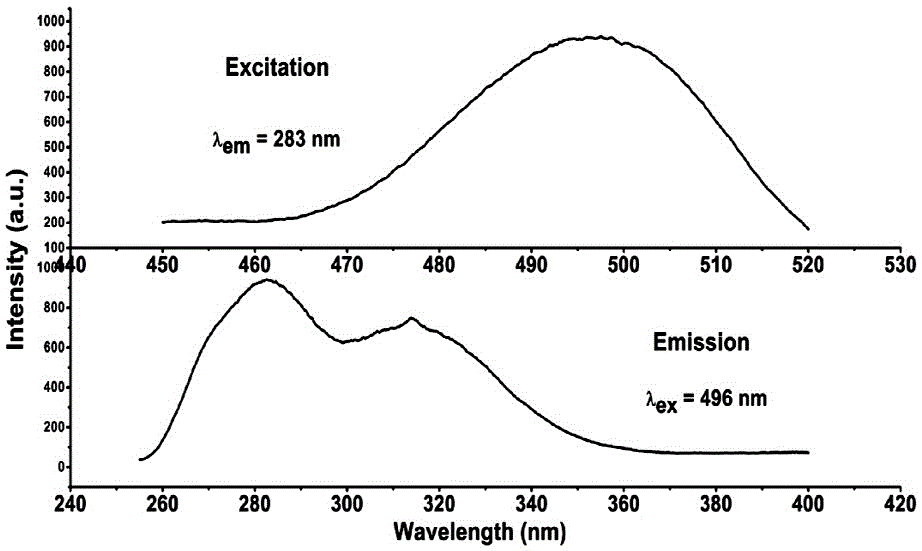

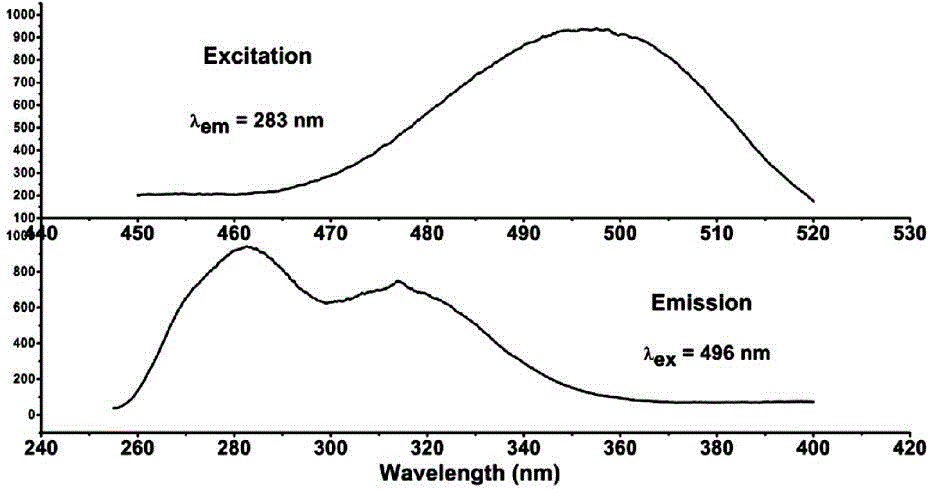

Phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, and preparation method and application thereof

InactiveCN105018089ASimple processEasy to operateFood preservationLuminescent compositionsUltraviolet lightsLED lamp

The present invention discloses a phosphate or metaphosphate based visible-ultraviolet up-conversion luminescence material doped with rare earth ions, wherein phosphate or metaphosphate serves as a substrate, and the substrate material is doped with Pr<3+>; a molar ratio of phosphate or metaphosphate to Pr<3+> is (0.9-3):(0.01-0.1). The present invention further provides a preparation process of the material, comprising: (a) according to the chemical formula, weighing oxide materials of corresponding elements and ammonium dihydrogen phosphate according to a stoichiometric ratio; and (b) grinding the weighed materials, burning the ground materials at the temperature of 850 to 950 DEG C for 2.5-4 h, cooling the materials to the room temperature, and grinding the materials to obtain a powder-like up-conversion luminescence material. It is experimentally proved that when excited by a common light source (such as an incandescent lamp, an xenon lamp, a fluorescent lamp and an LED lamp), especially by sunlight, the material can emit ultraviolet light UVC that can effectively kill bacteria; and the material has a broad application prospect in the fields of food safety and environmental protection.

Owner:HEBEI UNIVERSITY

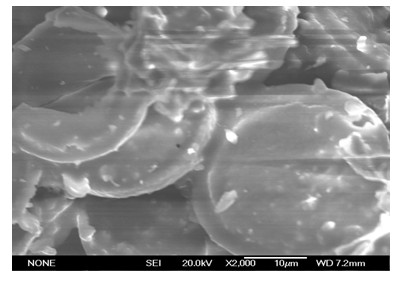

Preparation method of porous diatomite-based AgO ceramic material

InactiveCN102060561AHigh content of AgOSimple operation processCeramicwarePotassium persulfatePolyvinyl alcohol

The invention discloses a preparation method of a porous diatomite-based AgO ceramic material, comprising the following steps of: firstly, preparing fine diatomite by raw diatomite, mixing the find diatomite, water, sodium carbonate, polyacrylamide and polyvinyl alcohol to prepare wet powder, extruding and sintering the wet powder to prepare porous ceramic strips, and then preparing the porous ceramic strips into required ceramic particles; soaking the ceramic particles in a silver nitrate solution, adding a potassium persulfate solution and a potassium hydroxide solution into the solution for reaction for 1-4 hours, and filtering out the ceramic particles; and washing and drying the filtered ceramic particles to obtain the porous diatomite-based AgO ceramic material. The porous AgO-carried ceramic material is prepared with method provided by the invention, AgO is an efficient bactericide, and porous ceramic is a filter medium with high cost performance, thereby the prepared novel material can be used for sterilizing and filtering in water, reducing the loss of the AgO, and lowering the water treatment cost. The preparation method has the advantages of simplicity in process and preparation equipment, low preparation cost and no pollutant discharge.

Owner:XIAN UNIV OF TECH

Separation of tropical candiyeast strain and production of xylitol

ActiveCN1982460AHighlight substantiveSignificant progressMicroorganism based processesGenetic engineeringFiberHydrolysate

Separation of tropical moniliasis strain and production of xylitol are disclosed. The process is carried out by amplification culturing to obtain seed liquid, preparing hemicellulose hydrolyte culture medium, circulating and reutilizing. It has excellent sugar-tolerance and mithridatism. It could be used above time times.

Owner:唐传生物科技(厦门)有限公司

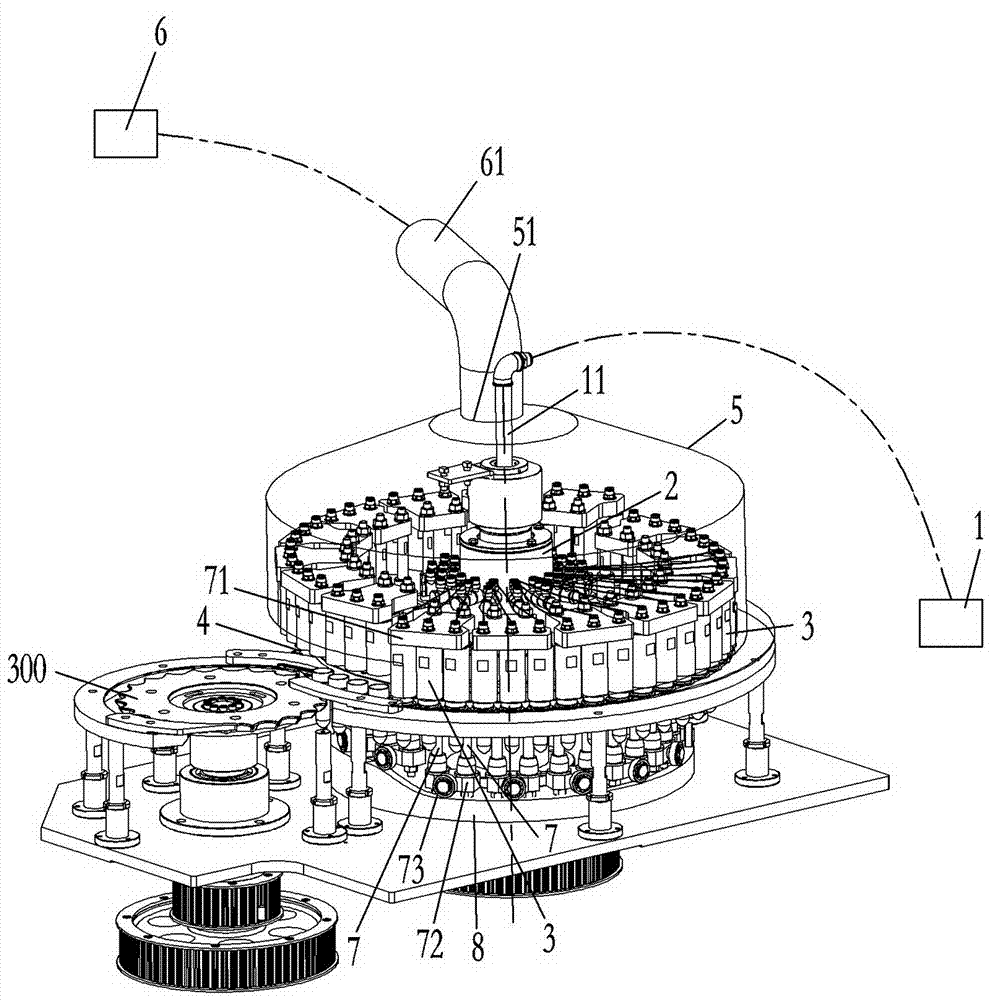

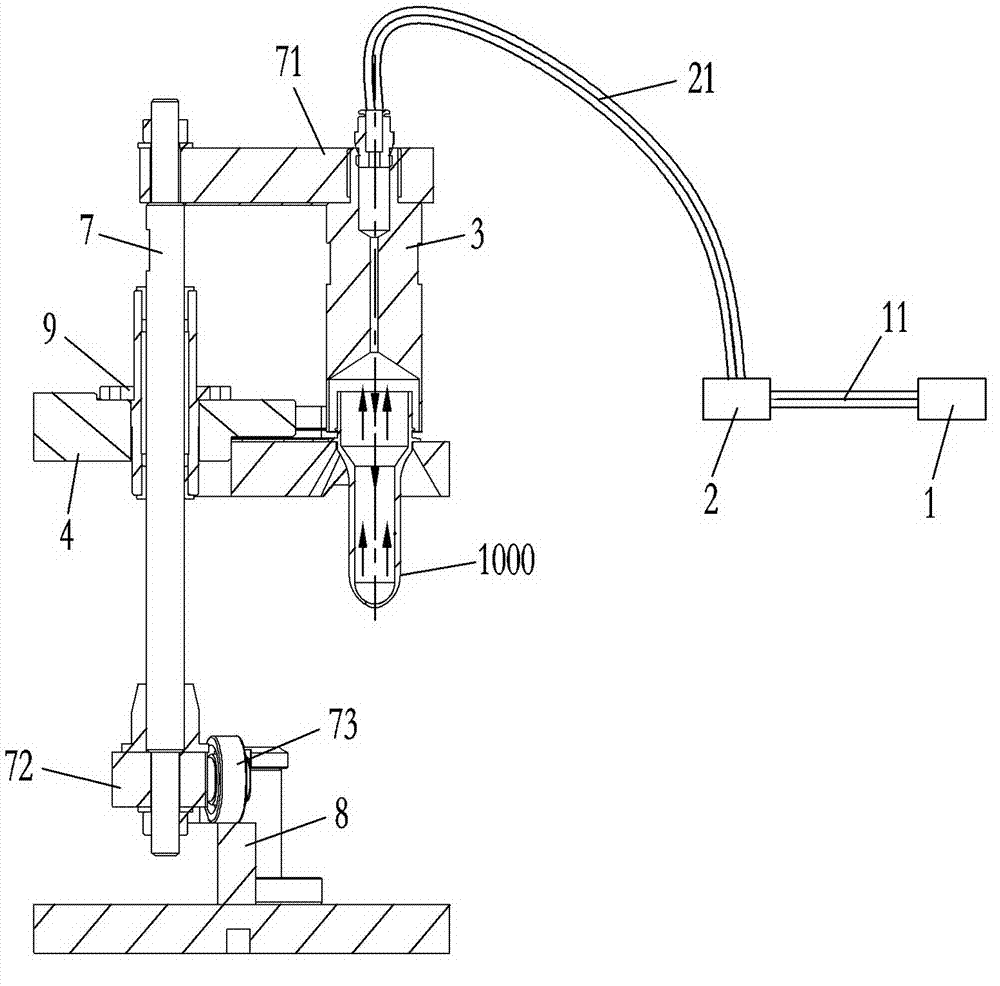

Sterilization device for bottle preforms

ActiveCN104511035ADoes not affect performanceWill not affect service lifeLavatory sanitoryChemicalsSpray nozzleEngineering

The invention discloses a sterilization device for bottle preforms. The sterilization device comprises a sterilizing agent treatment unit and multiple spray nozzles which are installed on a sterilization star-wheel plate and rotate along with the sterilization star-wheel plate, an air outlet end and an air inlet end of a sterilization steam distributor are respectively connected with the sterilizing agent treatment unit and the spray nozzles through conveying pipes, the spray nozzles are located over the bottle preforms grabbed by the sterilization star-wheel plate and can spray vaporized sterilizing agents into the bottle preforms, a recovery cover capable of covering the spray nozzles is arranged on the periphery of the sterilization star-wheel plate, an air outlet in the top of the recovery cover is communicated with a sterilizing agent recovery unit through a recovery pipe. The sterilization cost is low, the sterilization effect is good, and the sterilization device does not corrode a heating machine or other devices in the sterilization process.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

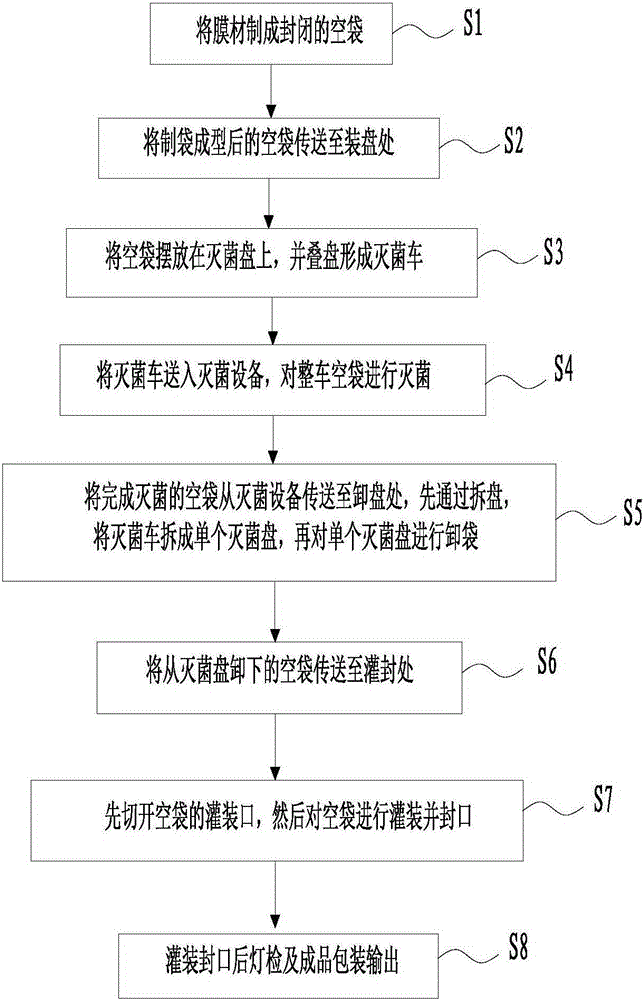

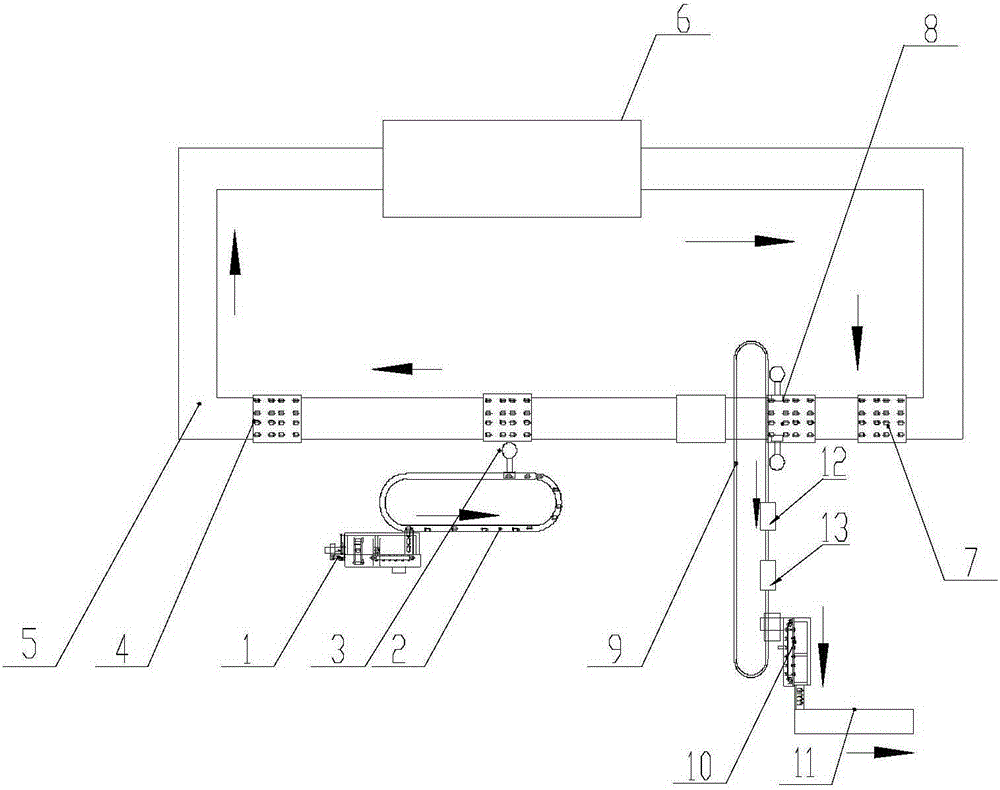

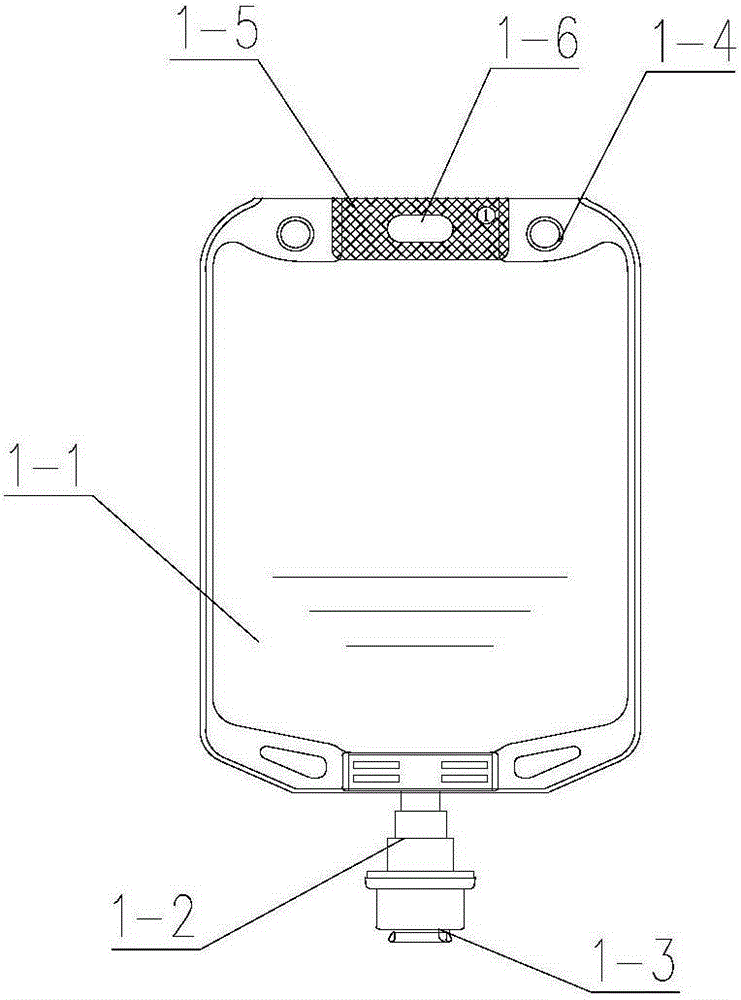

Non-sterile production method of soft package infusion terminal and bag making, filling and sealing device

ActiveCN105173248AAvoid changes in molecular structureHarm reductionPackage sterilisationLiquid materialEngineeringMechanical engineering

The invention discloses a non-sterile production method of a soft package infusion terminal. The non-sterile production method comprises the steps that bag making is conducted; conveying is conducted before sterilization, and sealed empty bags are conveyed to a tray loading position; trays are loaded with the empty bags, the empty bags are placed on the sterilization trays, and the trays are stacked, so that a sterilization trolley is formed; sterilization is conducted, the sterilization trays are conveyed into sterilization equipment, and the whole trolley of empty bags are sterilized; the empty bags are unloaded from the trays, the sterilized empty bags are conveyed to a tray unloading position from the sterilization equipment, the sterilization trolley is disassembled into the independent sterilization trays through tray disassembly, and then bag unloading is conducted on each sterilization tray; conveying after sterilization is conducted, the empty bags unloaded from the sterilization trays are conveyed to a filling and sealing position; and filling and sealing are conducted, and the empty bags are filled and sealed. According to the method, the empty bags are sterilized after bag making and before filling, and sterilization does not need to be conducted any more after the soft bags are filled and sealed; the protection technique is excellent, and potential safety hazards generated during sterilization of the soft bags can be obviously reduced; meanwhile, the sterilization cost of the soft bags is reduced, and the sterilization efficiency of the soft bags is improved. The invention further discloses a non-sterile bag making, filling and sealing device of the soft package infusion terminal.

Owner:SHINVA MEDICAL INSTR CO LTD

Supercritical CO2 sterilizing method of fluid food

InactiveCN101327034AMaintain shape and structureReduce the sterilization temperatureMilk preservationFood preservationFood preservationEnergy consumption

The invention relates to a supercritical CO2 sterilization method for liquid foods, which belongs to the food preservation method. By adopting CO2 in the supercritical state, and in the condition of pressure of 10-50 MPa and the temperature of 32-45 DEG C, liquid food is processed for 45 min-150 min, the purpose of commercial asepsis can be achieved, and simultaneously, continuous production can be realized by being matched with aseptic canning technology. The technology can be applied in the sterilization of fruit and vegetable juice, drink, milk or other liquid foods, and is a novel non-thermal sterilization technology. The sterilization technology is simple, the sterilization condition is easy to control, the sterilization temperature is low, the influence on the quality of foods is small, and the color, the smell and the taste, the shape and the structure of the foods can be maintained. No residual and pollution can be generated during the sterilization process, the energy consumption is low, CO2 is cheap and can be reused, and the operating cost is low.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

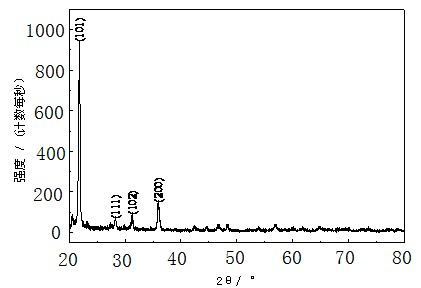

Silicate-based rare-earth ion doped visible-ultraviolet up-conversion luminescent material, and preparation method and application thereof

InactiveCN105018088AGrowth inhibitionAchieve sterilizationLuminescent compositionsUltraviolet lightsMesoporous silica

The present invention discloses a silicate-based rare-earth ion doped visible-ultraviolet up-conversion luminescent material, wherein silicate is used as a substrate; the substrate material is doped with Pr<3+> and Li<+>; and the molar ratio of the silicate:Pr<3+>:Li<+> is equal to (0.77-0.99):(0.01-0.03):(0-2). The present invention also provides a preparation method of the material. The preparation method comprises: weighing nitrate, carbonate or oxide raw material that contains corresponding metal elements according to a ratio, wherein a silicon source in use is mesoporous silica; dissolving the weighed materials into distilled water, dispersing the materials evenly to obtain a mixture, regulating the pH value of the mixture to be neutral, stirring the mixture, carrying out a hydrothermal reaction on the mixture at 100-120 DEG C for 18-25 hours, cooling the mixture, filtering the mixture, washing the mixture, and drying the mixture to obtain a powdered reaction product, roasting the reaction product, cooling the roasted reaction product, and then grinding the product to obtain a powdered up-conversion luminescent material. According to an experiment, the material can emit UVC ultraviolet light that can effectively kill bacteria under excitation of a normal light source (such as an incandescent lamp, an xenon lamp, a fluorescent lamp, and an LED lamp), particularly sunlight; and the material has a wide application prospect in food safety and environmental protection.

Owner:HEBEI UNIVERSITY

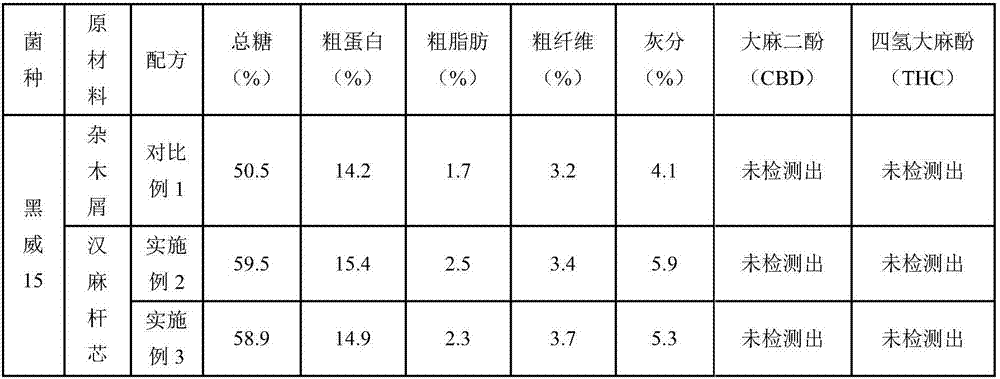

Culture medium containing China-hemp stalk cores and process used for cultivation of black funguses

ActiveCN107493974AAvoid wasting resourcesReduce the rate of bacterial contaminationCalcareous fertilisersBio-organic fraction processingMyceliumDisease

The invention belongs to the technical field of cultivation of black funguses, in particular to a culture medium containing China-hemp stalk cores and process used for cultivation of black funguses. The culture medium containing China-hemp stalk cores is prepared by crushing, weighing, stirring and sealed stack fermentation, bagging and sterilization of raw material. The raw material comprises the following ingredients including 50-82 parts by weight of China-hemp stalk cores, 0-32 parts by weight of mixed sawdust, 0-15 parts by weight of wheat bran, 0-15 parts by weight of rice bran, 1.5-3 parts by weight of bean flour, 0-1.5 parts by weight of lime, and 1 part of plaster. The culture medium containing China-hemp stalk cores is used for the process of cultivation of black funguses. The process comprises the following steps: inoculation, mycelium culture, after-ripening, formation of holes in cultivation bags, pregermination, fruiting management and harvesting and sun-drying. The resources of China-hemp stalk cores are applied to the technical field of cultivation of black funguses. Therefore, the resources of China-hemp stalk cores are reasonably utilized in order to avoid waste and environment pollution. The rich nutritional ingredients of China-hemp stalk cores are fully utilized. The natural and antibacterial feature and resistance to pests and diseases can effectively reduce the contamination rate during the cultivation process of black funguses so that yield and quality of black funguses are improved.

Owner:DAQING BRANCH OF HEILONGJIANG ACAD OF SCI +1

Environment-friendly explant sterilizing method and sterilizing solution

InactiveCN103918553AAchieving non-toxicityReduce sterilization costsBiocideFungicidesDistilled waterWeight/volume ratio

The invention discloses an environment-friendly explant sterilizing solution, namely a garlic aqueous solution, which is prepared by peeling the garlic, mashing, and then mixing with sterile distilled water according to a weight ratio (by volume) of (1-9):1. The invention further provides an environment-friendly explant sterilizing method based on the sterilizing solution, wherein plant explant is immersed into the garlic aqueous solution for sterilizing. The new explant sterilizing method, namely the garlic aqueous solution method is moderate for treated plants, high in sterilization rate which can be up to 100%, stable in sterilizing effect, simple to operate, low in cost, and friendly to environment.

Owner:DALIAN UNIV

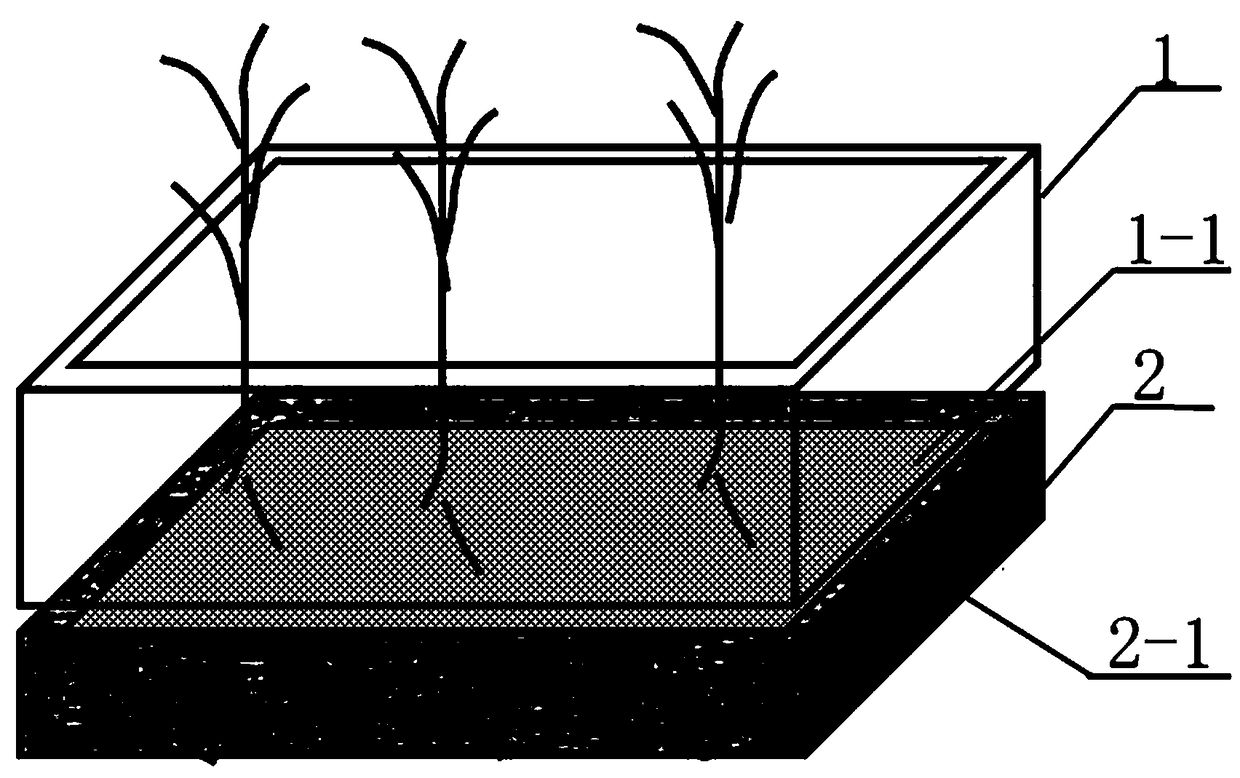

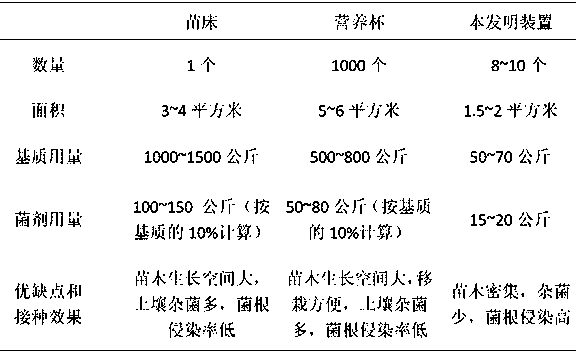

Seedling culture device and method for culturing mycorrhizal seedlings

ActiveCN108293504AHigh infection rateHigh densityCultivating equipmentsMushroom cultivationArbuscular mycorrhizal fungiDisinfectant

The invention discloses a seedling culture device and method for culturing mycorrhizal seedlings. The device comprises an upper layer and a lower layer, a seedling culture chamber is formed in the upper layer, and an inoculant chamber is formed in the lower layer. An opening is formed in the upper portion of the seedling culture chamber, the bottom of the seedling culture chamber is in a screen shape, and a PVC screen or an iron wire screen with the hole diameter being 2 mm is arranged at the bottom of the seedling culture chamber. An opening is formed in the upper portion of the inoculant chamber, the bottom of the inoculant chamber is sealed, and an arbuscular mycorrhizal fungal inoculant is put in the inoculant chamber. During seedling culture, the surfaces of seeds are disinfected with10% sodium hypochlorite or other disinfectants, and the surfaces of the seeds are completely washed with sterile water. A culture matrix or soil is subjected to hot-pressing sterilization, and then sowing and seedling culturing are carried out. The mycorrhizal seedlings are cultured through the seedling culture device, the seedling culture matrix is not mixed with the arbuscular mycorrhizal fungal inoculant, the inoculant only makes contact with root systems of the seedlings, the density of the inoculant around the root systems is increased, the root systems fully make contact with the inoculant, the infection rate of mycorhiza is increased, infection of other infectious microbes is reduced, the use quantity of the seedling culture matrix can be reduced, and the cost can be reduced.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

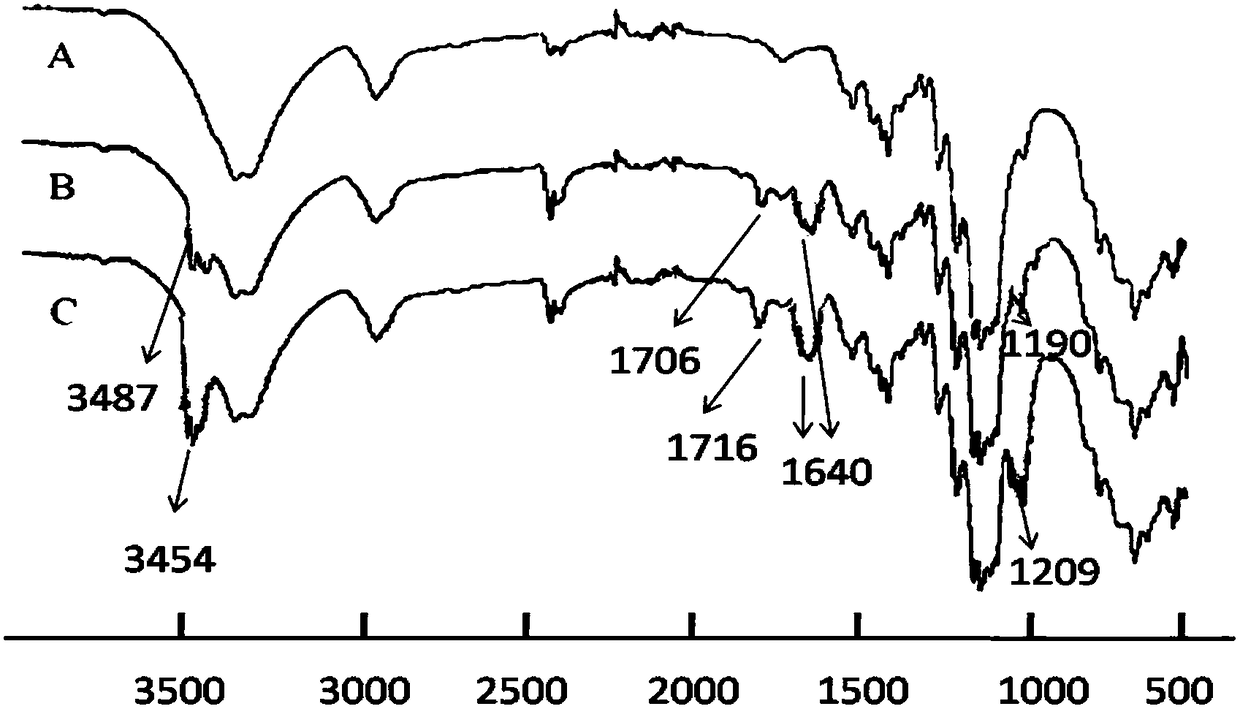

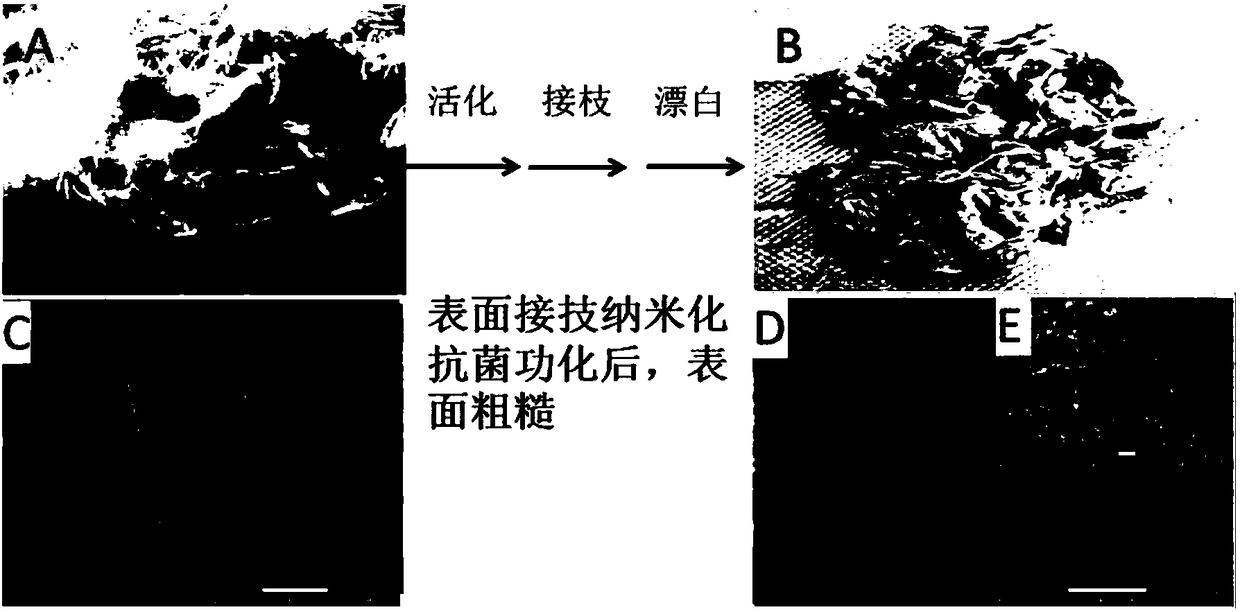

Preparation method and application of quaternary ammonium salt-N-halamine nano antibacterial fibers

ActiveCN108411626AEnhanced interactionExcellent contact typeVegetal fibresAnimal fibresQuaternary ammonium cationMedical equipment

The invention discloses a preparation method and application of quaternary ammonium salt-N-halamine nano antibacterial fibers. The preparation method includes: performing activation preprocessing on natural fibers, allowing the activated natural fibers to have grafting reaction with a multi-amino polymer compound or a multi-amino multi-sulfydryl polymer compound, then grafting with quaternary ammonium salt, using a crosslinking agent to perform crosslinking, and bleaching to obtain the quaternary ammonium salt-N-halamine nano antibacterial fibers. The prepared quaternary ammonium salt-N-halamine nano antibacterial fibers have contact type and release type bifunctional antibacterial functions and are capable of increasing sterilizing speed, capable of achieving sterilizing under normal temperature, high in sterilizing performance, lasting in effect, less prone to tolerance generation, widely applicable to many fields such food packages, food fresh-keeping, medical equipment, public sanitation and water purification systems and promising in application prospect.

Owner:YULIN NORMAL UNIVERSITY

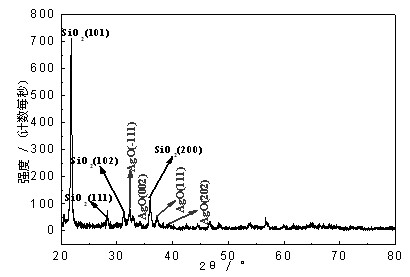

Rare earth ions doped fluoride matrix visible-ultraviolet upconversion luminescence material, preparation method therefor and application thereof

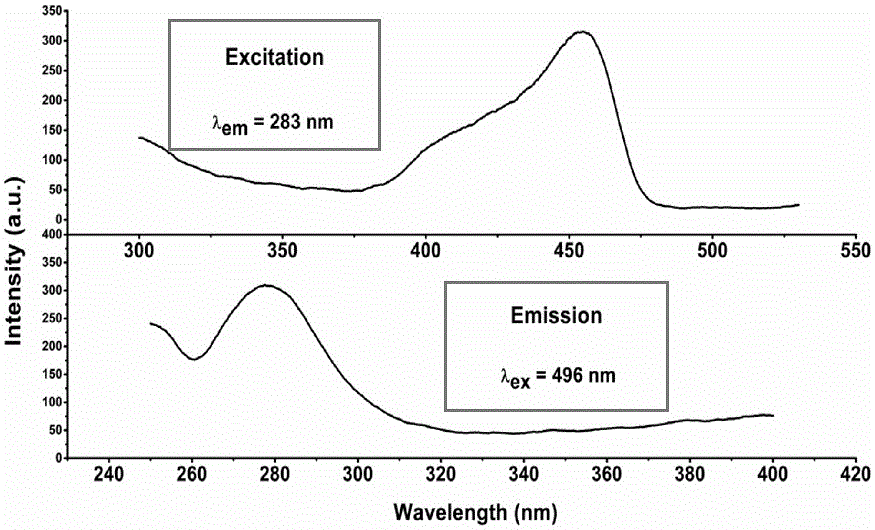

ActiveCN104927864ASimple processEasy to operateLuminescent compositionsRadiationUltraviolet lightsLED lamp

The invention discloses a rare earth ions doped fluoride matrix visible-ultraviolet upconversion luminescence material. In the material, fluoride acts as a matrix, Pr3+ is doped in the matrix material, and the molar ratio of elements is: fluoride:Pr3+ = 0.7-0.99:0.01-0.1. In addition, the invention further provides a preparation process of the material. The preparation process comprises: (a), according to the chemical formula, precisely weighing out a carbonate material or an oxide material of the corresponding element and ammonium biphosphate in accordance with the stoichiometric ratio; and (b) grinding the material into powder, burning the material at the temperature of 700-1,000 DEG C for 1.5-4 h, cooling the material to the room temperature, and grinding the material to obtain a powdery upconversion luminescence material. It is experimentally proved that the material, when excited by a common light source (such as an incandescent lamp, an xenon lamp, a fluorescent lamp, or an LED lamp) or especially sunlight, can emit UVC ultraviolet light capable of effectively killing bacteria. The material has better application prospects concerning food safety and environmental protection.

Owner:HEBEI UNIVERSITY

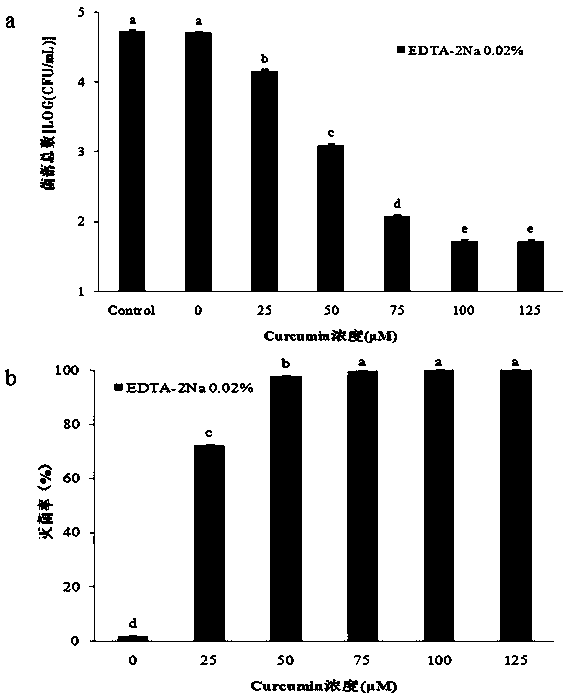

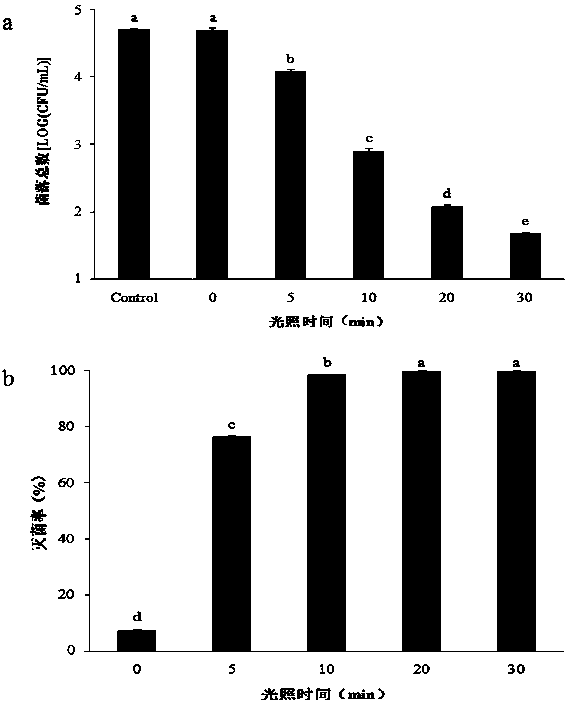

Photodynamic sterilization fresh-keeping film for packaging ready-to-eat jellyfish

ActiveCN109517226AHigh sterilization rateImprove the bactericidal effectFruit and vegetables preservationFood ingredient for microbe protectionFlavorReady to eat

The invention discloses a photodynamic sterilization fresh-keeping film for packaging ready-to-eat jellyfish. The photodynamic sterilization fresh-keeping film is prepared in the mode that food-gradecurcumin and food-grade EDTA disodium are compounded to serve as a photosensitizer compound, chitosan and glycerinum are combined to serve as a matrix material, and a solution-casting method is conducted. After the photodynamic sterilization fresh-keeping film is adopted to package the ready-to-eat jellyfish, the photodynamic sterilization fresh-keeping film is matched with non-toxic LED visible light sources for use, and thus the aerobic bacterial count on the ready-to-eat jellyfish is effectively decreased. The tests show that the disinfection rate of the photodynamic sterilization fresh-keeping film on the ready-to-eat jellyfish is up to 99.9%, the sterilization effect is significant, the flavor and taste of the ready-to-eat jellyfish are not significantly affected, the shelf life of the ready-to-eat jellyfish can be prolonged from one month to five months, and the food safety problem of the ready-to-eat jellyfish is ensured.

Owner:FUJIAN AGRI & FORESTRY UNIV

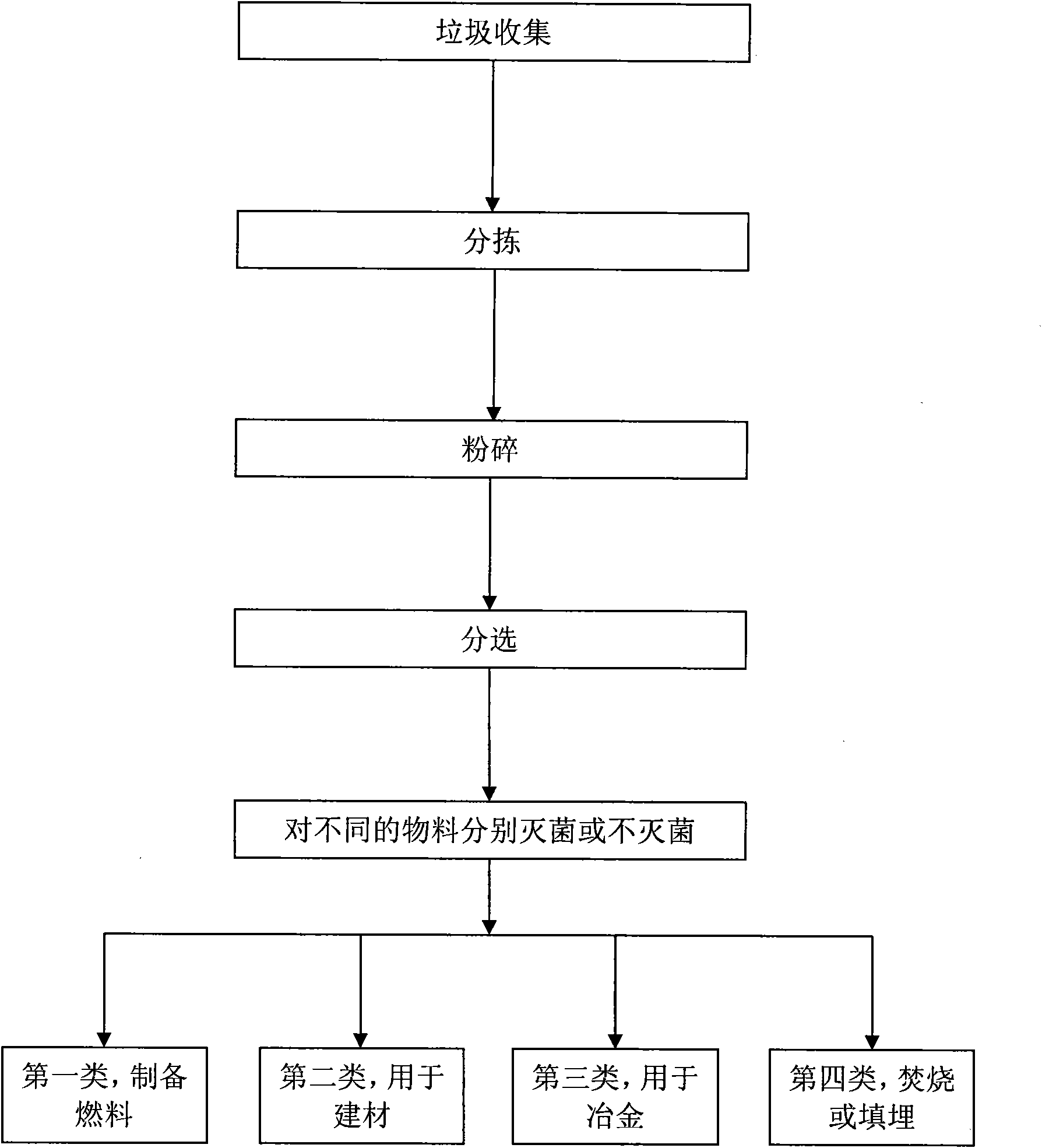

Medical garbage treatment and fuel preparation method

InactiveCN101590485AHigh recycling valueIncrease the proportion of recyclingSolid waste disposalBiofuelsWaste collectionEngineering

The invention relates to a medical garbage treatment and fuel preparation method. The pre-treatment and separating of the medical garbage comprise the following steps: (1) garbage collecting; (2) sorting; (3) crushing; (4) separating: according to the specific weight and magnetism of materials, separating the medical garbage into four types: lighter materials, heavier materials, magnetic materials and residual materials; (5) sterilizing the lighter materials, the heavier materials and the magnetic materials in different methods, directly sealing and pressing the residual materials into blocks; (6) burning and recycling: the heavier materials and the magnetic materials are separately recycled, the residual materials are burnt when the lighter materials is recycled as follows: the materials are crushed and mixed with smoke coal powder in 100:30-40 ratio, then proper binding agent is added, after adding water and blending the mixture, the mixture is pressed and molded by a former and dried by air to form bulk fuel. The invention facilitates recycling of physical resources and reduces energy consumption and air pollution.

Owner:BEIJING JINAOHUARONG TECH

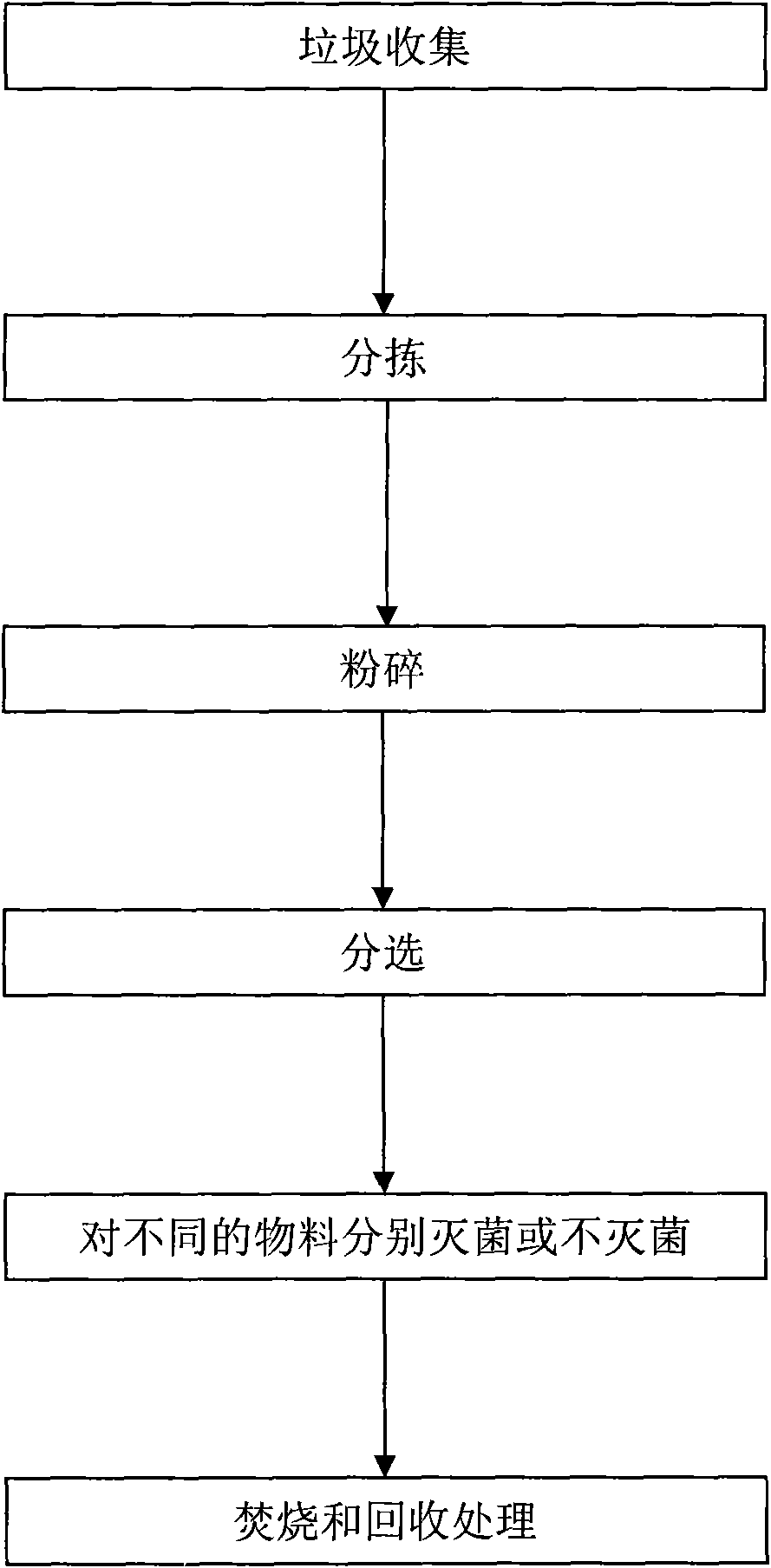

Medical garbage sorting sterilization treatment method

InactiveCN101590482AHigh recycling valueIncrease the proportion of recyclingSolid waste disposalMedical waste disposalRefuse collectionWaste collection

The invention relates to a medical garbage sorting sterilization treatment method, comprising the following steps: (1) garbage collecting: adopting to a sealed way to collect garbage; (2) sorting: separating the chunk materials and the bulk materials which can be recycled separately; (3) crushing: crushing all the materials needed to be treated together in a sealing condition; (4) separating: according to the specific weight and magnetism of materials, separating the medical garbage into four types by a mechanical way: lighter materials, heavier materials, magnetic materials and residual materials; (5) sterilizing: sterilizing the lighter materials, the heavier materials and the magnetic materials in different ways, and sealing and pressing the residual materials into blocks directly without sterilizing; (6) burning and recycling: recycling the lighter materials, the heavier materials and the magnetic materials and burning the residual materials by sending the materials into a special garbage incinerator. The invention facilitates recycling of physical resources and reduces energy consumption and air pollution.

Owner:BEIJING JINAOHUARONG TECH

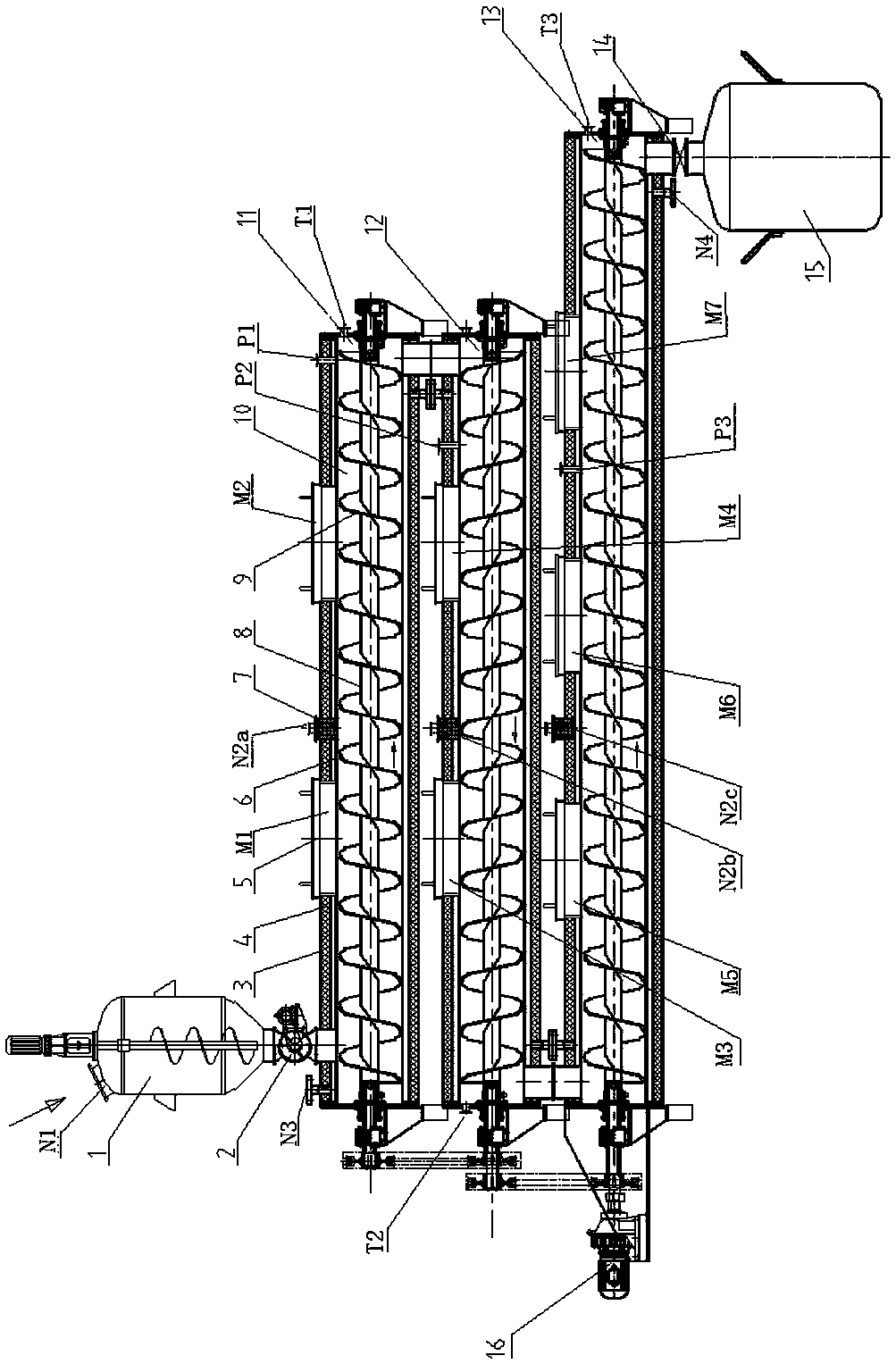

Dry-heat low-pressure continuous sterilization method

ActiveCN110522929AReduce the sterilization temperatureBreak through technical difficulties in the field of sterilizationLavatory sanitoryHeatPositive pressureEngineering

The invention belongs to the technical field of material sterilization. The invention relates to a dry-heat low-pressure continuous sterilization method. A sterilization inner cavity is heated througha heating device; the sterilization inner cavity is vacuumized through a vacuum device; the temperature of the sterilization inner cavity is adjusted and set during sterilization; materials are fed from one end of the tubular sterilization inner cavity, the material is conveyed from a feeding port to a discharging port through a conveying packing auger. In the sterilization process, the maintaining time of the vacuum degree and the pressure is controlled according to the number of microorganisms and the water content of materials, in the material conveying process, sterilization is conductedat the temperature lower than 100 DEG C under the positive-pressure and negative-pressure combined action, and the sterilization time is adjusted by adjusting the staying time of the materials in thesterilization inner cavity by adjusting the rotating speed of the conveying auger. A traditional dry heat sterilization mode is combined with preset positive and negative pressure, a physical sterilization process without any sterilizing agent works under a relatively low temperature condition, the medicine property of the materials is kept, and continuous sterilization is realized.

Owner:江西赫柏康华制药设备有限公司 +1

Borate-based rare earth ion doping visible-ultraviolet up-conversion luminescent material and preparation method and application thereof

ActiveCN106497558AAchieve growthAchieve bactericidal effectBiocideDisinfectantsAlkaline earth metalUltraviolet

The invention discloses a borate-based rare earth ion doping visible-ultraviolet up-conversion luminescent material. The borate is used as a matrix, and the matrix is doped with Pr<3+>or Pr<3+> and Li<+>; calculating in molar ratio, borate:Pr<3>+:Li<+>=0.9-2.05:0.01-0.1:0-0.09; and the borate is alkaline earth borate, transition metal borate, and alkaline earth borate containing metal yttrium. At the same time, the invention further provides a preparation method for the material. The preparation method comprises the following steps: (a) according to the chemical composition, weighing the oxide raw material of corresponding element and boric acid according to the stoichiometric proportion; (b) after grinding and smashing the weighed material, firing, cooling to the room temperature, grinding to obtain the luminescent material. The experiment shows that the material can emit the ultraviolet-c (UVC) capable of effectively killing bacteria under the excitation of normal light sources (such as a filament lamp, a xenon lamp, a fluorescent lamp and an LED lamp), particularly sunlight. The material has better application prospect in the fields, such as the food safety and environment protection.

Owner:HEBEI UNIVERSITY

Novel explant used in plant tissue culture and sterilizing method for novel explant

InactiveCN103907534AExtend vaccination timeDifficulties that are difficult to sterilize to overcomePlant tissue cultureHorticulture methodsVegetationShoot

The invention discloses a novel explant used in plant tissue culture. A tender shoot in the vegetation season is taken as an explant. The tender shoot is a segment of new shoot or branch of 5-10 centimeters in length below the stem top of a plant in the vegetation season. The invention further discloses a sterilizing method of the tender shoot explant. The sterilizing method comprises the following steps: preparing a sterilizing aqueous solution by using garlic; and soaking the tender shoot into the solution for sterilizing. The tender shoot in the vegetation season is taken as the explant for tissue culture, so that the application range of the plant tissue culture explant is expanded; the inoculation time of the explant under a natural condition is prolonged; compared with conventional leaf bud and stem tissue culture, in the invention, the combination of the tender shoot in the vegetation season and the garlic solution has the advantages that the tissue culture time is shortened, the tissue culture cost is reduced, and the operation is relatively easy.

Owner:DALIAN UNIV

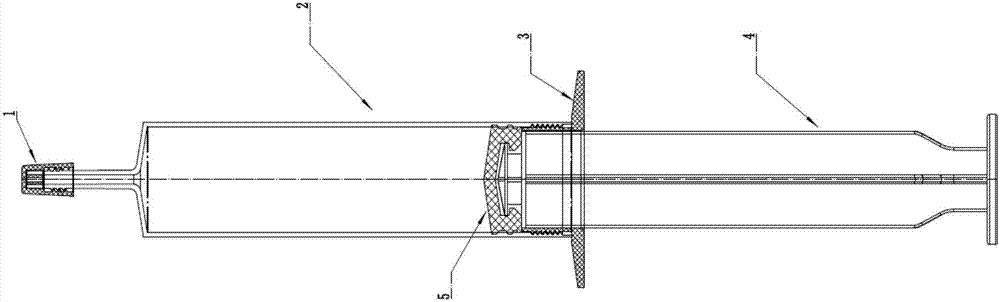

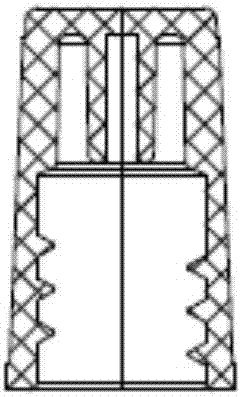

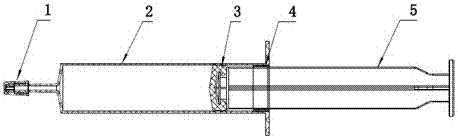

Pre-filled injector

PendingCN107441593APrevent leakagePlay a role in stopping retreatInfusion syringesMedical devicesScrew threadBiomedical engineering

The invention belongs to the technical field of injectors and discloses a pre-filled injector. The pre-filled injector comprises a tubing cap, a needle tubing, a handle, a push bar and a piston, the front end of the handle is provided with an inner thread, an outer thread is arranged in the needle tubing and close to the handle end, the handle and the needle tubing are assembled rotatably in a threaded manner, the front end of the needle tubing is provided with an outer thread, the tubing cap is provided with an inner thread, the tubing cap and the needle tubing are assembled rotatably in a threaded manner, the outer diameter of the push bar is matched in size with the inner diameter of the handle, and the outer diameter of the piston is matched in size with the inner diameter of the needle tubing; during assembly, the push bar penetrates the handle to be assembled with the piston, the assembled handle is in threaded connection with the needle tubing, and assembly is locked to form a retaining structure. A filling machine is characterized in that a certain amount of liquid medicine is injected to the injector from the top end of the needle tubing, the tubing cap and the needle tubing are rotatably assembled in a threaded manner and locked hermetically, and then the injector is sent to a sterilization bin for steam sterilization for 30 minutes at a high temperature of 121DEG C.

Owner:石家庄鑫富达医药包装有限公司

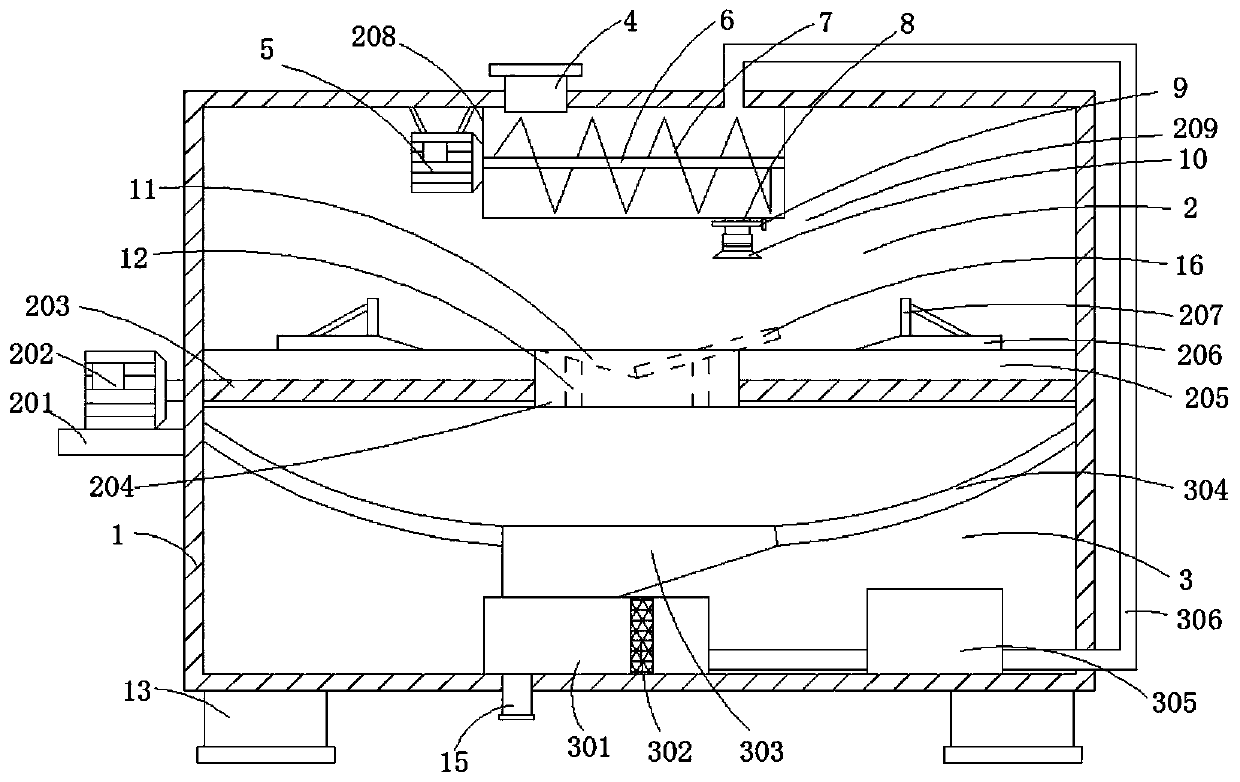

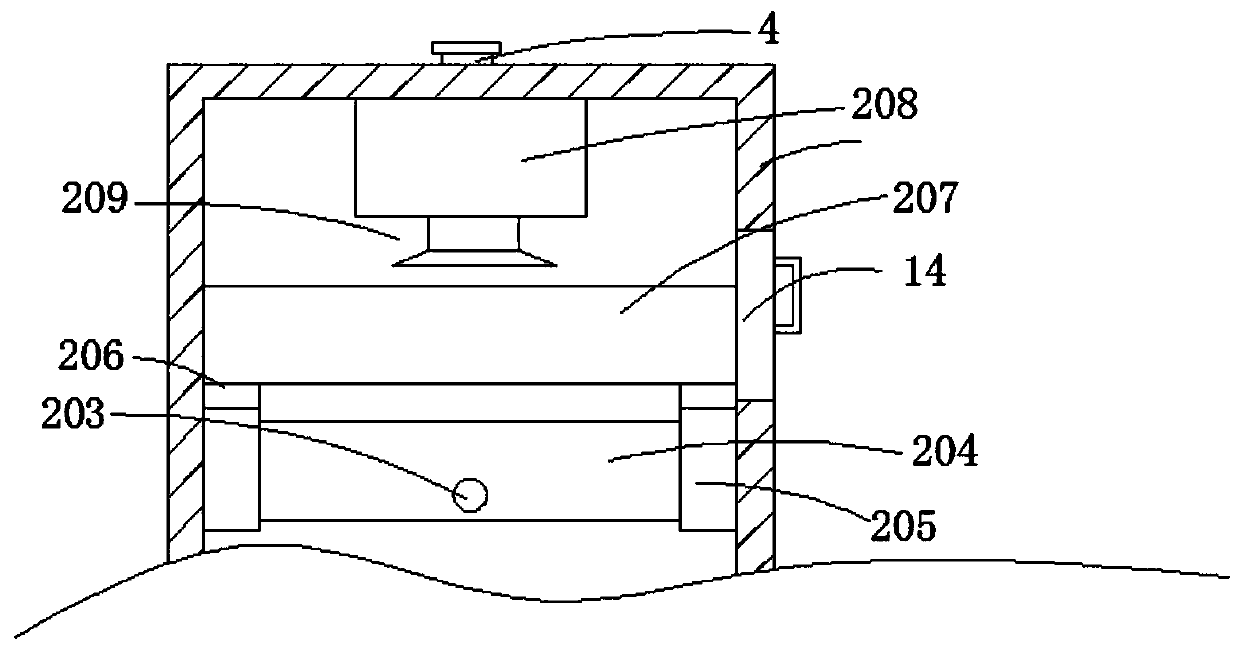

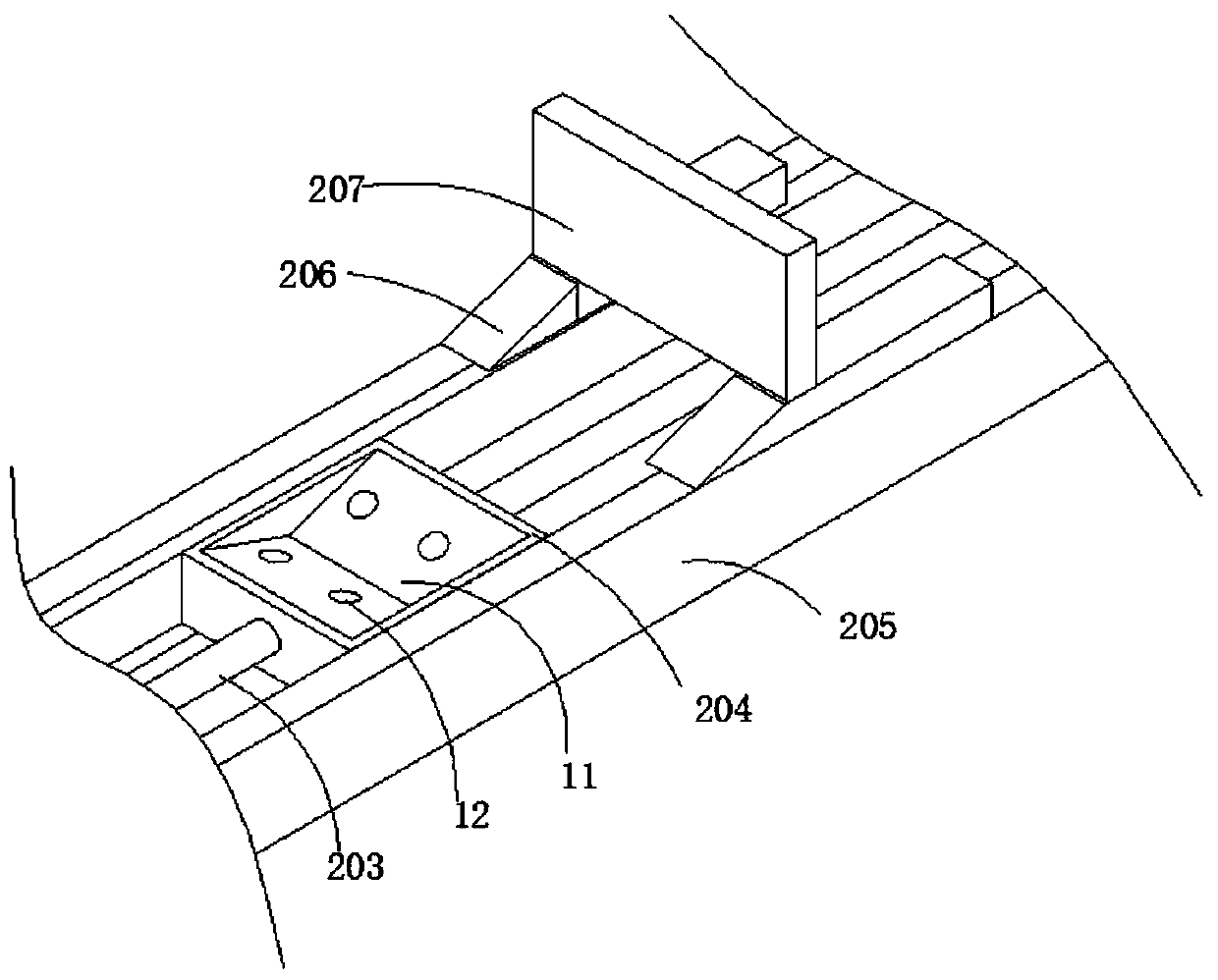

Sterilization equipment used in frozen food production process

The invention provides sterilization equipment used in a frozen food production process and relates to the field of food production equipment. The sterilization equipment comprises a main box, a sterilization mechanism and a recycling mechanism, wherein a servo motor is mounted at the top of a motor table, one end of a screw rod is rotationally connected to an output end of the servo motor, the other end extends to the inner side of the main box, a side plate is fixedly connected to the inner wall of the main box, a movable table is in threaded connection onto the screw rod, an adjusting blockis fixedly connected to the top of the side plate, a baffle is fixedly connected to the top of the adjusting block, a sterilization liquid box is fixedly connected to the top of an inner cavity of the main box, and a spray head assembly is mounted at the bottom of the sterilization liquid box. By arrangement of the sterilization mechanism, a sterilization liquid is sprayed to sterilize frozen food, the frozen food is turned over by the adjusting block and the baffle, so that two sides of the food are uniformly sprayed, the sterilization effect is improved, the sterilization liquid is low in cost, high in continuous sterilization capacity, degradable, safe and environmentally friendly.

Owner:江苏荣泽食品有限公司

Electrolytic sterilization method and device for oilfield sewage

InactiveCN104310541ANo drug resistanceImprove the bactericidal effectWaste water treatment from quariesWater/sewage treatment using germicide/oligodynamic-processElectrolysisSodium hypochlorite solution

The invention discloses an electrolytic sterilization method and device for oilfield sewage, and belongs to the field of oilfield oily sewage treatment. For the problem that bacterial resistance is easily produced in the existing oilfield sewage sterilization process, the invention provides an electrolytic sterilization method and device for oilfield sewage, which avoid bacterial resistance, have a stable sterilization effect, can realize continuous sterilization and have low sterilization cost compared with a chemical sterilization method. The method comprises the steps of performing electrolysis to produce a sodium hypochlorite solution, reacting the sodium hypochlorite solution produced by electrolysis with the oilfield sewage in a mixed reaction tank, and filtering the reacted sewage, wherein the pH value of the sewage entering the mixed reaction tank is 6.5-7.5, and the concentration of the sodium hypochlorite solution entering an electrolytic bath is 3.0-3.5%.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

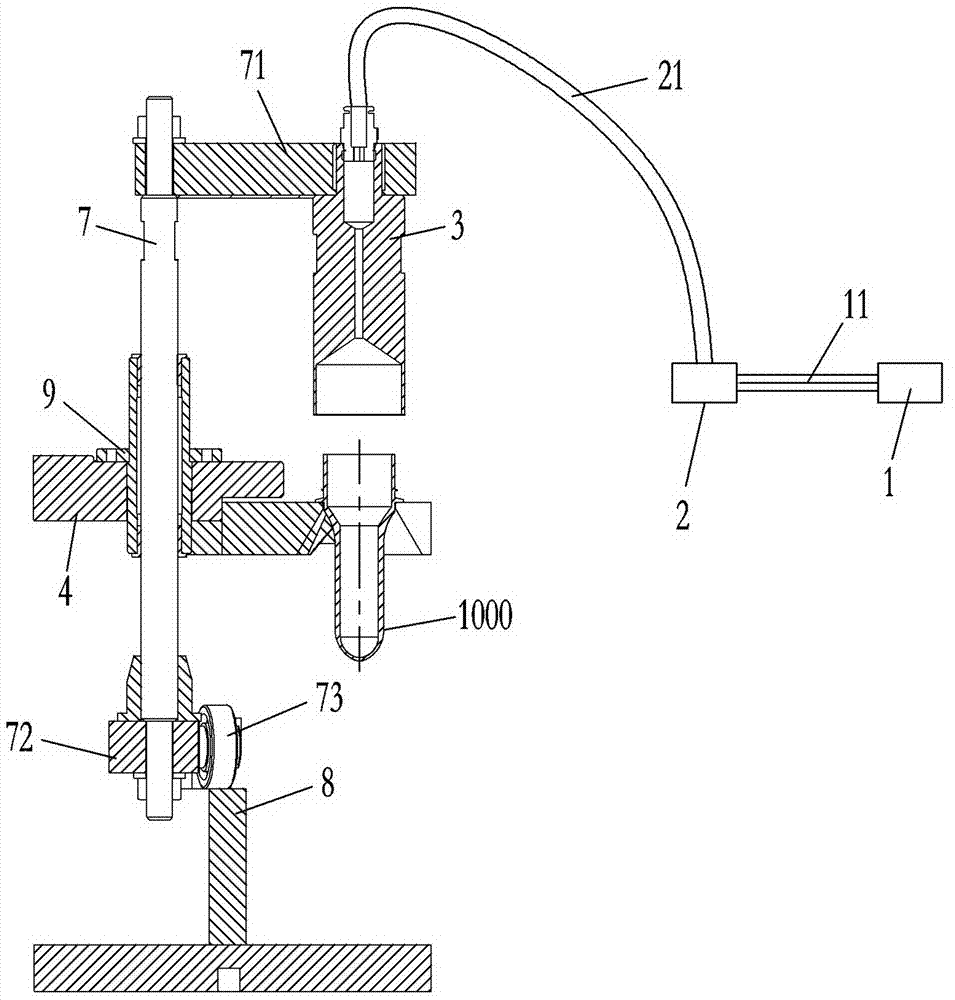

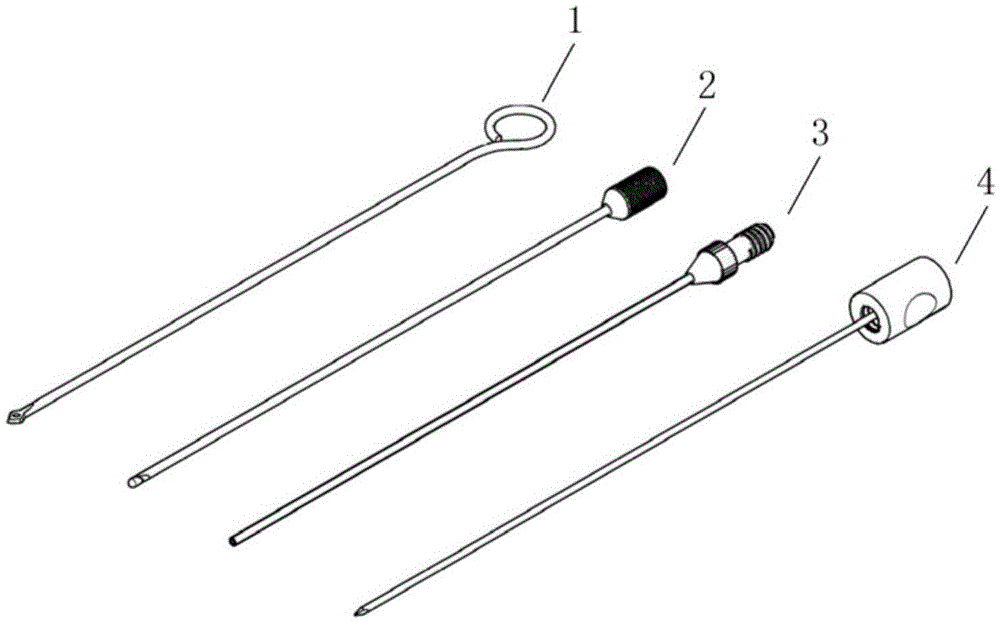

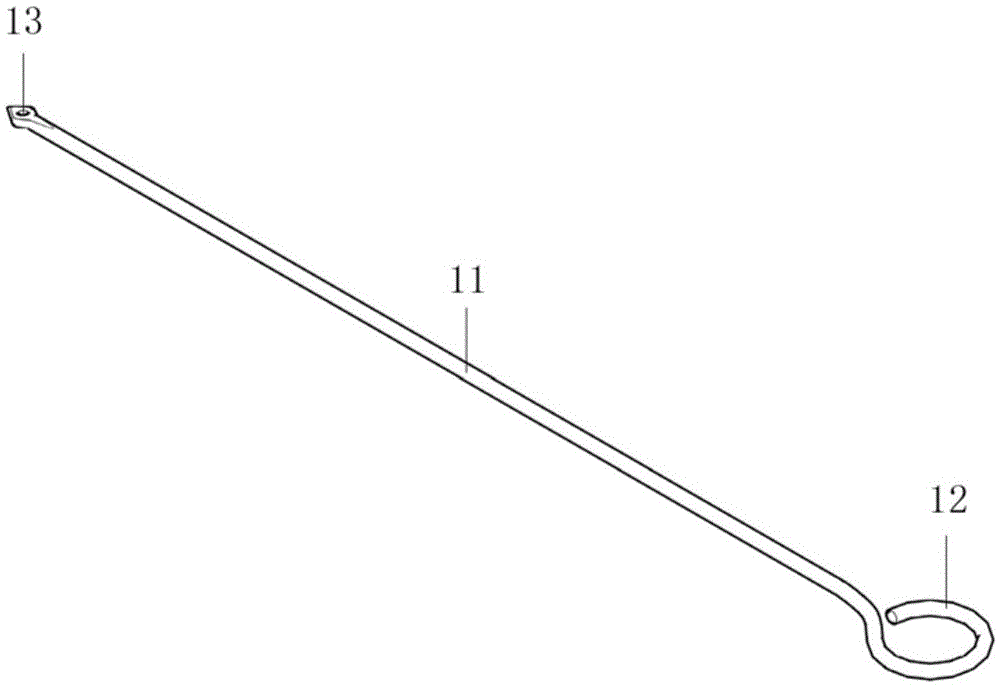

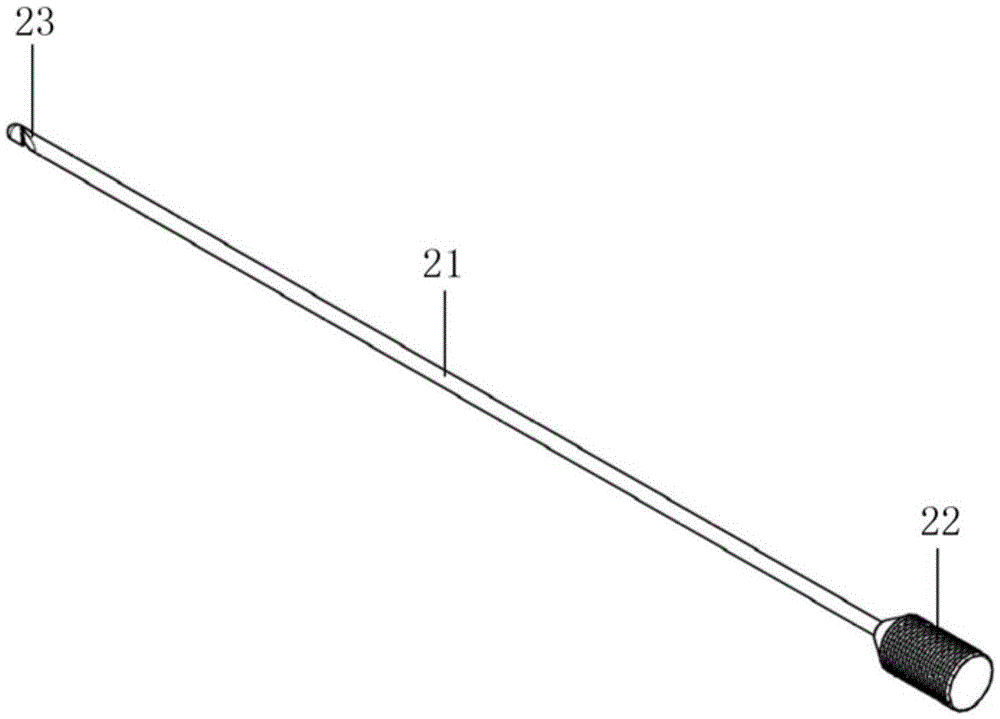

Apparatus of hernia laparoscopic surgery for children

The invention relates to an apparatus of hernia laparoscopic surgery for children, and belongs to the technical field of medical apparatuses and instruments. The apparatus is composed of a threading needle, a suture hooking needle, a hollow puncture needle sheath and a puncture needle. The needle head of the threading needle is sharp and provided with a small hole. A groove is formed in the needle head of the suture hooking needle. An external thread is arranged on the tail of the puncture needle sheath. The needle head of the puncture needle is sharp. An internal thread matched with the external thread on the tail of the puncture needle sheath is arranged on the tail of the puncture needle. The apparatus has the advantages of being easy and convenient to operate, small in injury to patients, convenient to disinfect and sterilize, capable of conducting autoclaving, low in cost, capable of being repeatedly used, high in utilization rate and low in use cost.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

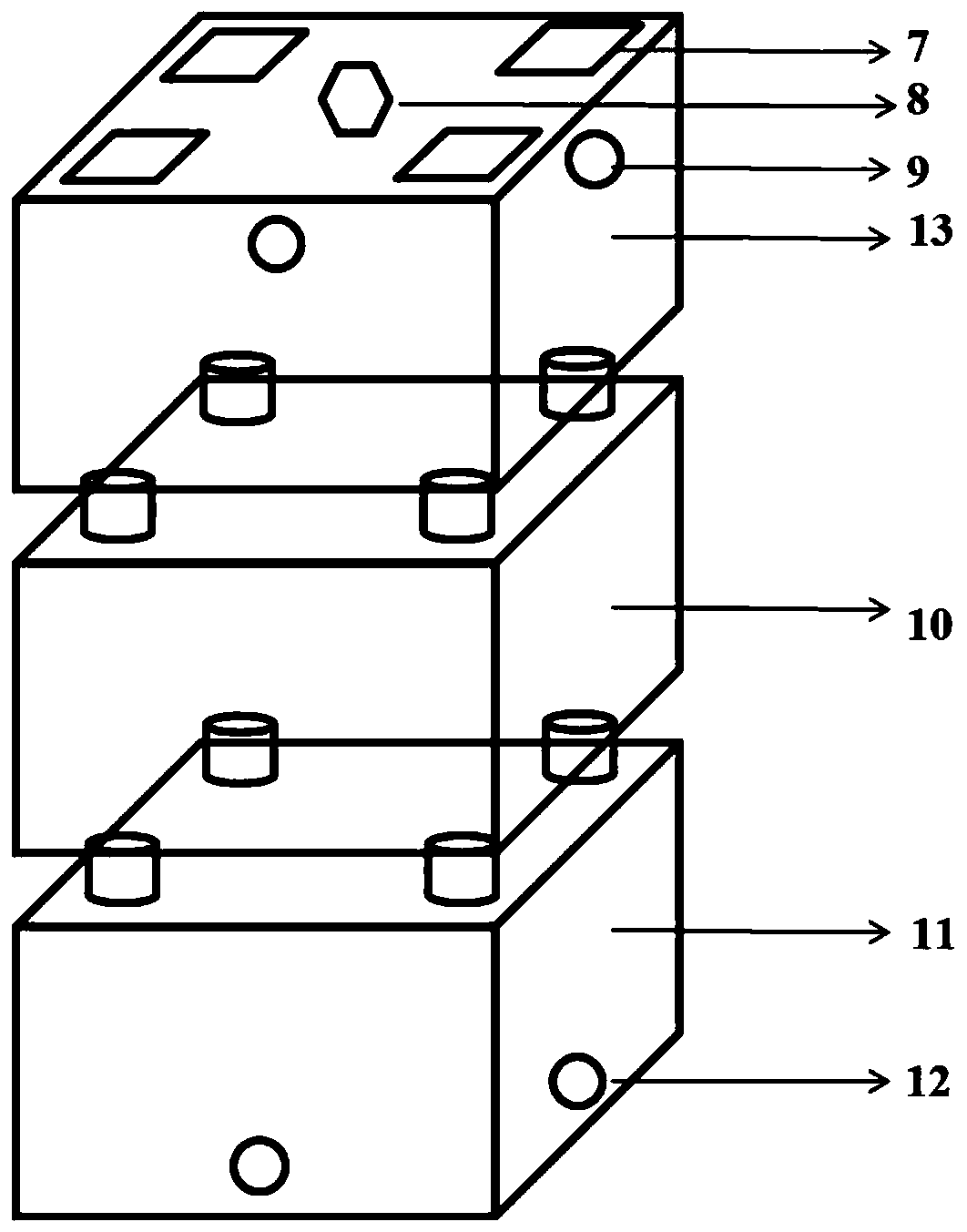

Sterilization method of edible fungus stick

InactiveCN106613323AReduce pollutionLow pollution rateCultivating equipmentsMushroom cultivationMicrowave powerBiology

The invention discloses a sterilization method of an edible fungus stick. The sterilization procedure contains 6 periods: temperature increasing I, temperature preservation I, temperature increasing II, intermittent temperature increasing I, temperature preservation II and intermittent temperature increasing II. The microwave power in temperature increasing I is 1.5-2.0 kW, and the sterilization time is 12-40 min; the microwave power in temperature increasing II is 1.0-1.5 kW, and the sterilization time is 0-60 min; the microwave power in intermittent temperature increasing I is 0.5-1.0 kW, the time in intermittent temperature increasing I comprises microwave work time and intermittent time, each time is 0-60 seconds, and total time is 0-200 min; the microwave power in intermittent temperature increasing II is 0.2-0.5 kW, the time in intermittent temperature increasing I comprises microwave work time and intermittent time, each microwave time is 0-20 seconds, intermittent time is 0-40 seconds, and total time is 0-500 min; the time in temperature preservation I is 0-60 min; the time in temperature preservation II is 0-60 min. The problems of traditional steam sterilization of being long in sterilization time, low in efficiency, high in cost and prone to environmental pollution are solved, and edible fungus stick steam sterilization is a safe, efficient, energy-saving and environment-friendly sterilization method.

Owner:HEZHOU UNIV

Preparation process of cell-wall-disrupytion bee pollen beans or bee pollen sheets without additives

InactiveCN106616717AQuality improvementEasy to carryFood ingredient functionsFood additiveFood safety

The invention discloses a preparation process of cell-wall-disrupytion bee pollen beans or bee pollen sheets without additives. The preparation process comprises the following steps: taking bee pollen raw materials; drying; carrying out cell wall disrupytion; and adding purified water to pelletize and press to obtain the bee pollen beans or bee pollen sheets, and preferably further can comprise the steps of packing and sterilizing. According to the preparation method of the bee pollen beans or bee pollen sheets, only a solid preparation which is mechanically processed into beans or the bee pollen sheets is used, any auxiliaries or food additives are not added, food safety problems caused by food additives do not exist, the original fragrance of bee pollen is kept, the utilization rate of nutritional ingredients of the bee pollen is high and full, and the cell-wall-disrupytion bee pollen beans or bee pollen sheets without additives are stable and reliable in quality, convenient to carry and easy to use.

Owner:成都牧蜂人生物药业有限公司

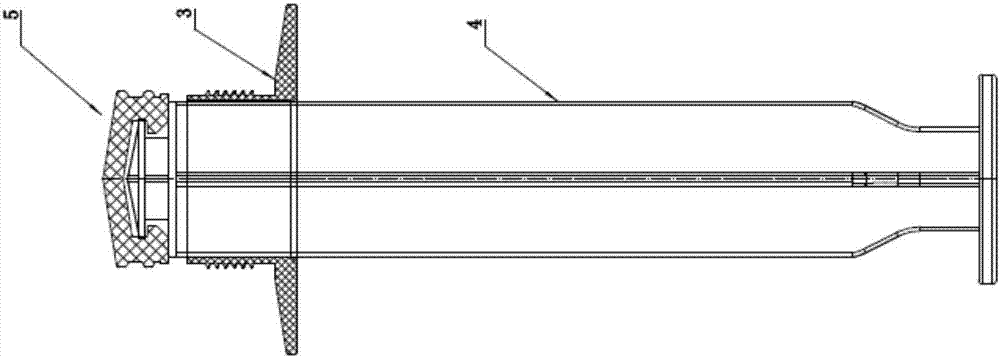

Pre-filled high-temperature sterilization syringe

PendingCN107469194AGuaranteed aseptic qualitySolving resource constraintsEnemata/irrigatorsIntravenous devicesInterference fitDrug injection

The invention belongs to the technical field of syringes, in particular suitable for a drug injection mode for animals, and discloses a pre-filled high-temperature sterilization syringe. The pre-filled high-temperature sterilization syringe comprises a tube cap, a needle tube, a push rod and a piston, wherein the part, near the handle end of the needle tube, of the needle tube is provided with a stop ring, and the front end of the needle tube is provided with an external thread; the tube cap is provided with an internal thread, and the tube cap and the needle tube are assembled through rotation of the threads; the outer diameter of the push rod is matched with the inner diameter of a handle, and the outer diameter of the piston and the inner diameter of the needle tube are in an interference fit for sealing; the stop ring is welded to the part, near the handle end of the needle tube, of the needle tube, and during assembly, the push rod runs through the inner hole of the handle and assembled with the piston so as to form a locking structure after assembly. According to the pre-filled high-temperature sterilization syringe, a filling machine is used to inject a certain amount of drug liquid through the top of the needle tube of the syringe, the tube cap and the needle tube are assembled through rotation of the threads so that sealing and locking can be achieved, and the syringe is delivered into a sterilization chamber for steam sterilization at a high temperature of 121 DEG C for 30 minutes.

Owner:石家庄鑫富达医药包装有限公司

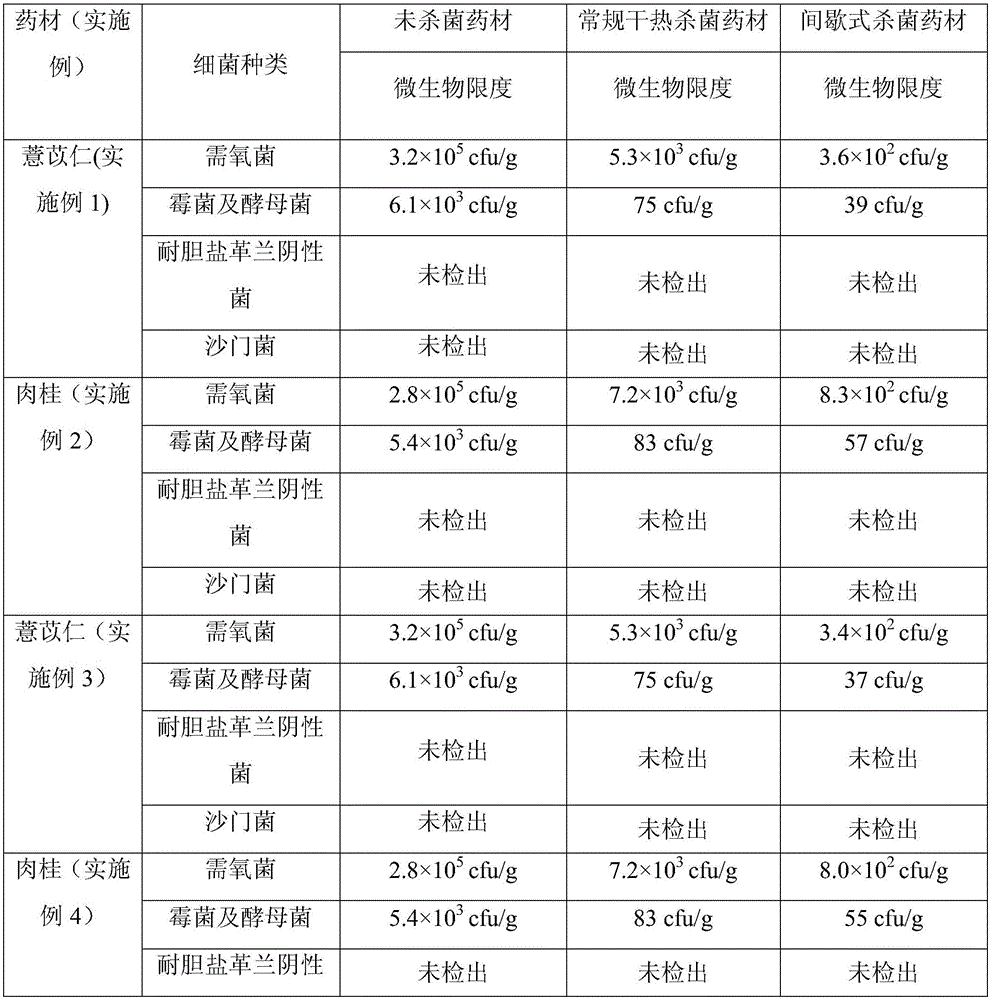

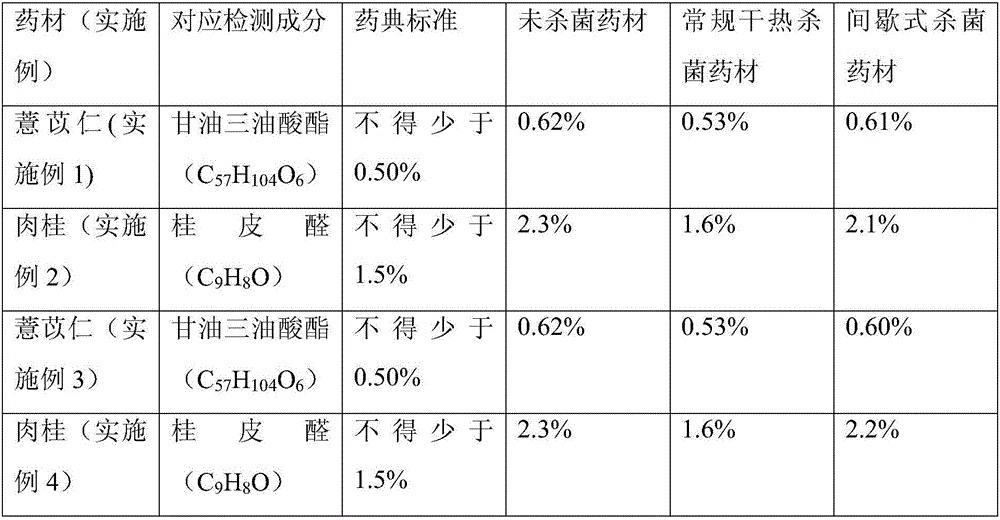

Crude medicine powder intermittent sterilization method

InactiveCN105999317AGuaranteed growth environmentAvoid enteringPowder deliveryHeatMedicineSoft materials

The invention provides a crude medicine powder intermittent sterilization method. The method comprises pretreating traditional Chinese medicines through a conventional method to obtain crude medicine powder, carrying out bacterial reproductive body killing, hypopus growth and reproductive body re-killing to obtain crude medicine powder satisfying microbial limit requirements, and carrying out wall-breaking crushing, soft material preparation, granulation, drying and coating to obtain a wall-broken decoction piece. The method hardly influences medicinal material effects. The product satisfies microbe limit requirements and guarantees drug use safety and effectiveness.

Owner:湖南盟合投资管理有限公司

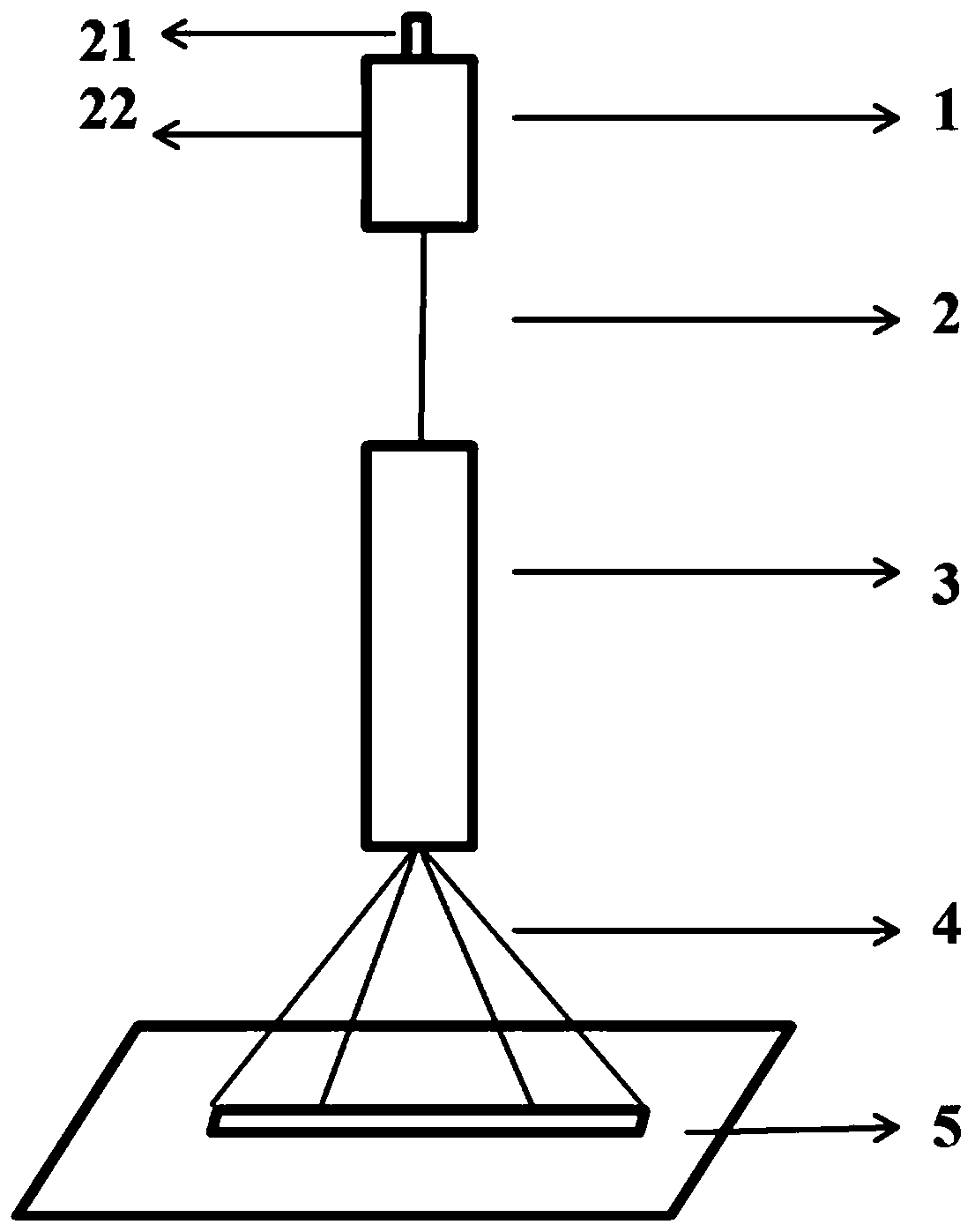

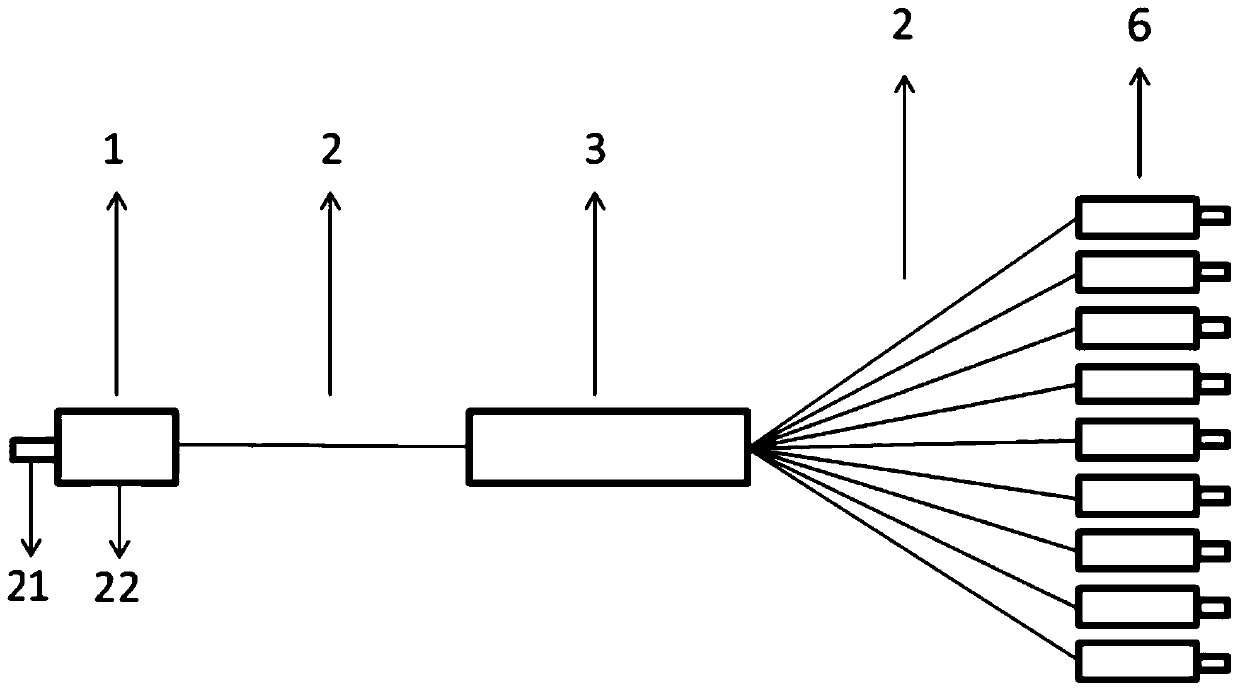

Movable ultraviolet LED sterilization and disinfection device

PendingCN111481694AFirmly connectedRealization of UV LED sterilization and disinfectionLavatory sanitoryDeodrantsUltravioletProcess engineering

The invention discloses a movable ultraviolet LED sterilization and disinfection device which comprises a box body. An ultraviolet LED sterilization mechanism, a fan, a storage battery pack and a controller are arranged in the box body; a movable platform is arranged at the bottom of the box body; a top probe is arranged at the top of the box body; and a bottom probe is arranged at the bottom of the box body. The device of the invention has the beneficial effects that the optical fiber coupled ultraviolet LED sterilization and disinfection device and the movable platform are combined into a whole, connection is convenient, and movable ultraviolet LED sterilization and disinfection are achieved; each system can be modularly produced and is easy to assemble and maintain, so that the manufacturing cost and the maintenance cost are greatly saved; an ultraviolet LED chip used for ultraviolet LED sterilization and disinfection is small in occupied space, and the device can be small, exquisite and light; besides an ultraviolet LED sterilization mode, the device can spray a disinfectant at the same time, and sterilization and disinfection are more thorough; the device can be applied to various occasions such as subway carriages, high-speed rail carriages, canteens and food and drug processing workshops, and is low in sterilization cost, efficient and rapid.

Owner:梁旭东

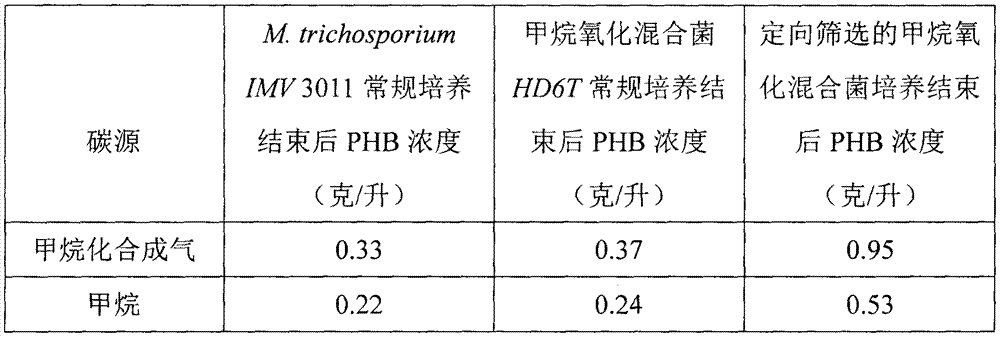

Method for biosynthesizing poly-beta-hydroxy butyric acid (PHB) by utilizing mixed methane-oxidizing bacteria

InactiveCN104513847AIncrease contentSimple extraction processMicroorganism based processesFermentationInorganic saltsButyric acid

The invention relates to a PHB biosynthesizing method, in particular to a method for biosynthesizing poly-beta-hydroxy butyric acid (PHB) by utilizing mixed methane-oxidizing bacteria, and aims to solve the problem of high extraction cost of the PHB caused by low content of the PHB in current mixed bacteria and the problem that methane-oxidizing bacteria are quickly inactivated and cannot grow due to impurities in synthesis gas. The method comprises the following steps: 1, inoculating a bacterium solution of the mixed methane-oxidizing bacteria into an inorganic salt culture medium for culturing, and replacing mixed gas at a time interval of 12h during the period; 2, continuously culturing the bacterium solution, replacing air at a time interval of 24h during the period, putting half of a culture into the inorganic salt culture medium after culturing is finished, and continuously performing habituated culture for 10 times to obtain the mixed methane-oxidizing bacteria which are capable of growing in the mixed gas and are rich in the PHB; 3, inoculating the mixed methane-oxidizing bacteria which are obtained by screening into the inorganic salt culture medium, replacing the air with the mixed gas, performing culturing, ending culturing, and determining the content of the PHB. The method is used for synthesizing the PHB.

Owner:HARBIN UNIV OF COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com