Dry-heat low-pressure continuous sterilization method

A sterilization method and low-pressure technology, applied in heating, toilet sanitary equipment, water supply equipment, etc., can solve the problems of destroying components, changing components, and easy pollution, so as to reduce sterilization costs, increase material yield, and occupy small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

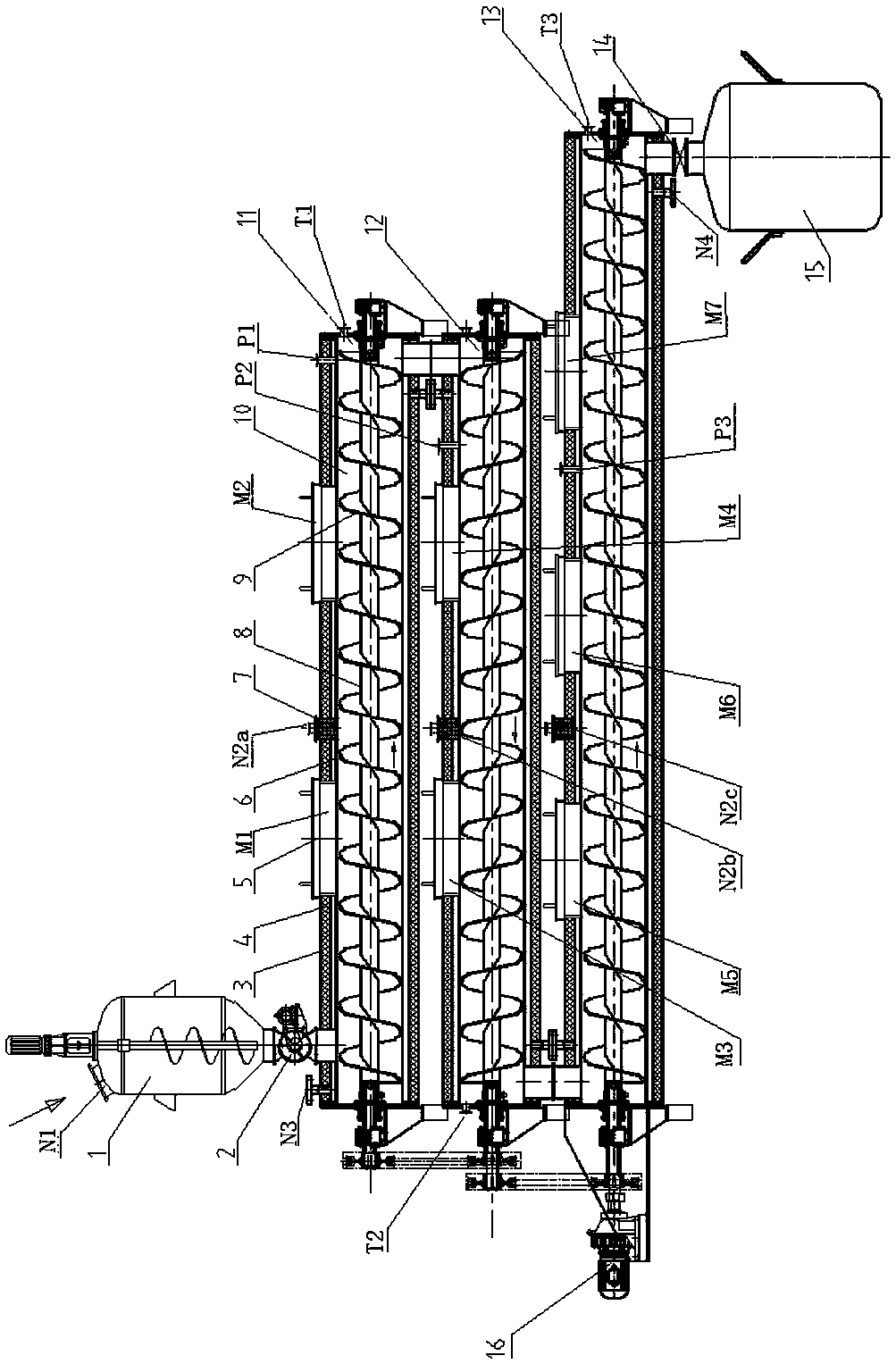

[0034] In order to meet the technical needs of dry heat and low pressure continuous sterilization, the present invention designs a dry heat and low pressure continuous sterilization device as shown in Figure 1, but the realization of the sterilization process of the present invention is not limited to the dry heat and low pressure shown in Figure 1 Continuous sterilization unit.

[0035] The dry heat and low pressure continuous sterilization device includes three long cylindrical sterilization cylinders, a feed hopper 1, a receiving hopper 15, etc., and each sterilization cylinder includes a sterilization cylinder shell 3, a sterilization cylinder insulation layer 4, and a sterilization cylinder. Collet jacket 6, sterilization inner chamber 10, sterilization cartridge shell 3 is located in the outermost layer, the innermost layer is the sterilization inner chamber 10, the sterilization inner chamber 10 outsources the sterilization cartridge jacket 6, and the sterilization cartr...

Embodiment 2

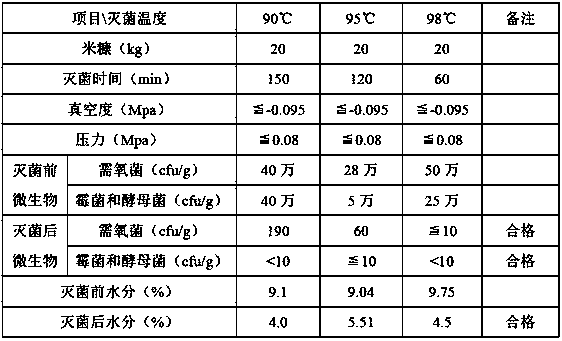

[0044] Adding rice bran as material for sterilization experiment:

[0045] (1) Measure the microbial quantity and water content of rice bran before sterilization; then add rice bran into hopper 1;

[0046] (2) First pass steam into the conveying auger and the jacket 6 of the sterilization cylinder, heat the temperature of the sterilization inner chamber 10 to 90°C through the steam, and vacuumize the sterilization inner chamber 10 to reach the predetermined temperature. temperature and vacuum.

[0047] (3) Start the reducer 16, open the feed valve 2, make the rice bran in the feed hopper 1 fall into the sterilization chamber 10, and move forward under the action of the conveying auger. According to the number of microorganisms and water content of rice bran, the negative pressure vacuum degree, positive pressure pressure, vacuum degree and pressure maintenance time in the sterilization inner cavity 10 are controlled. The vacuum degree is 0-0.095Mpa and the pressure is 0-0.08M...

Embodiment 3

[0050] (1) Measure the microbial quantity and water content of rice bran before sterilization; then add rice bran into hopper 1;

[0051] (2) First pass steam into the conveying auger and the jacket 6 of the sterilization cylinder, heat the temperature of the sterilization inner chamber 10 to 95°C through the steam, and vacuumize the sterilization inner chamber 10 to reach the predetermined temperature. temperature and vacuum. ;

[0052] (3) Start the reducer 16, open the feed valve 2, make the rice bran in the feed hopper 1 fall into the sterilization chamber 10, and move forward under the action of the conveying auger. According to the number of microorganisms and water content of rice bran, the negative pressure vacuum degree, positive pressure pressure, vacuum degree and pressure maintenance time in the sterilization inner cavity 10 are controlled. The vacuum degree is 0-0.095Mpa and the pressure is 0-0.08Mpa. The speed of the variable frequency motor carried by the redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com