Sterilization method and sterilization device for canned tangerines

A sterilization device, citrus technology, applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., to achieve uniform heating, short treatment time, and better sterilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

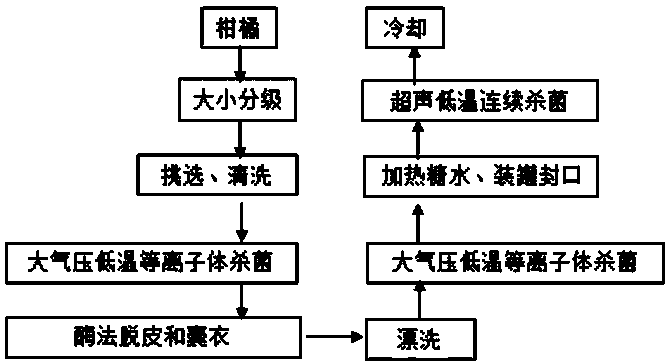

[0051] A kind of sterilizing method of canned citrus, technological process is as follows figure 1 shown, including the following steps:

[0052] (1) After the citrus is graded with a fruit size classifier, the rotten citrus is manually selected and removed, and the citrus is cleaned with cleaning equipment.

[0053] (2) Transport the cleaned citrus to the lower end of the atmospheric-pressure low-temperature plasma jet generator, and use the atmospheric-pressure low-temperature plasma sterilization method to sterilize the surface. The atmospheric-pressure low-temperature plasma is driven by DC voltage, the working gas is air, and the DC voltage is 25kV. The gas temperature is 50°C, the loop ballast resistance is 70kΩ, and the sterilization time is 100s.

[0054] (3) Remove the citrus peel and capsule from the sterilized citrus by enzymatic method. The specific process is: use a puncture needle with a length of 3mm and a cloth needle density of 2 needles / cm 3 The needle bed ...

Embodiment 2

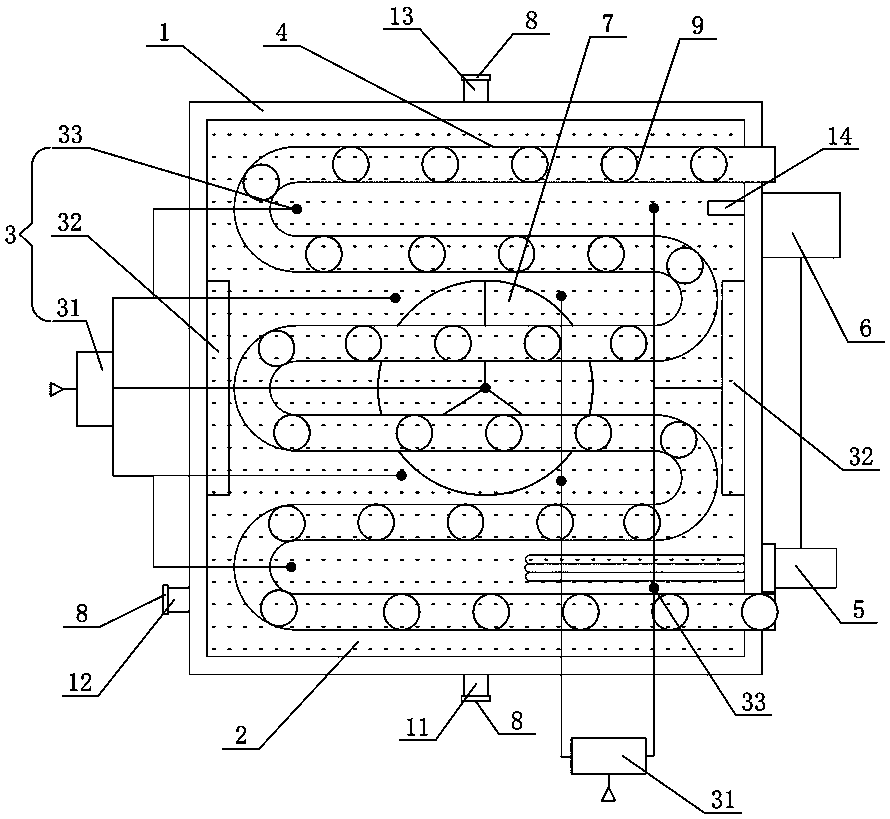

[0061] A sterilizing device for canned citrus according to the present invention, which can be used for ultrasonic low-temperature continuous sterilization in step (6) of Example 1, but is not limited thereto. figure 2 The canned citrus sterilizing device of this embodiment is shown, including a sterilizing tank 1, a sterilizing medium 2 and an ultrasonic assembly 3 for emitting ultrasonic sterilization, the sterilizing medium 2 is arranged in the sterilizing tank 1, and the sterilizing tank 1 passes through the sterilizing medium 2 A conveying track 4 for conveying the cans 9 is provided, and a heating element 5 for heating the sterilizing medium 2 is installed on the side wall of the sterilizing tank 1 . In this structure, the sterilizing tank 1 is made of strong, elastic, and corrosion-resistant high-quality stainless steel. The sterilizing tank 1 is set as an open tank, and its upper end is not sealed or covered, so it can be observed and sampled at any time; the transmiss...

Embodiment 3

[0073] A kind of sterilization method of canned citrus of the present invention, such as figure 1 shown, including the following steps:

[0074] (1) After the citrus is graded with a fruit size classifier, the rotten citrus is manually selected and removed, and the citrus is cleaned with cleaning equipment.

[0075] (2) The cleaned citrus is subjected to low-temperature surface sterilization by atmospheric pressure low-temperature plasma sterilization. The atmospheric pressure low-temperature plasma is driven by DC voltage, the working gas is air, the DC voltage is 25kV, the gas temperature is 50°C, and the loop ballast resistance is 70kΩ , The sterilization time is 100s.

[0076] (3) Remove the citrus peel and capsule from the sterilized citrus by enzymatic method. The specific process is: puncture the surface of the citrus with a needle bed with a needle length of 3 mm and a needle density of 6 needles / cm3, and then pierce the punctured citrus. The citrus was soaked in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com