Medical garbage treatment and fuel preparation method

A medical waste and fuel technology, which is applied in the direction of combustion methods, chemical instruments and methods, waste disinfection or sterilization methods, etc., can solve problems such as air pollution, loss of recyclable materials, fuel consumption, etc., to reduce processing costs and reduce Sterilization costs, effects of reducing the amount of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

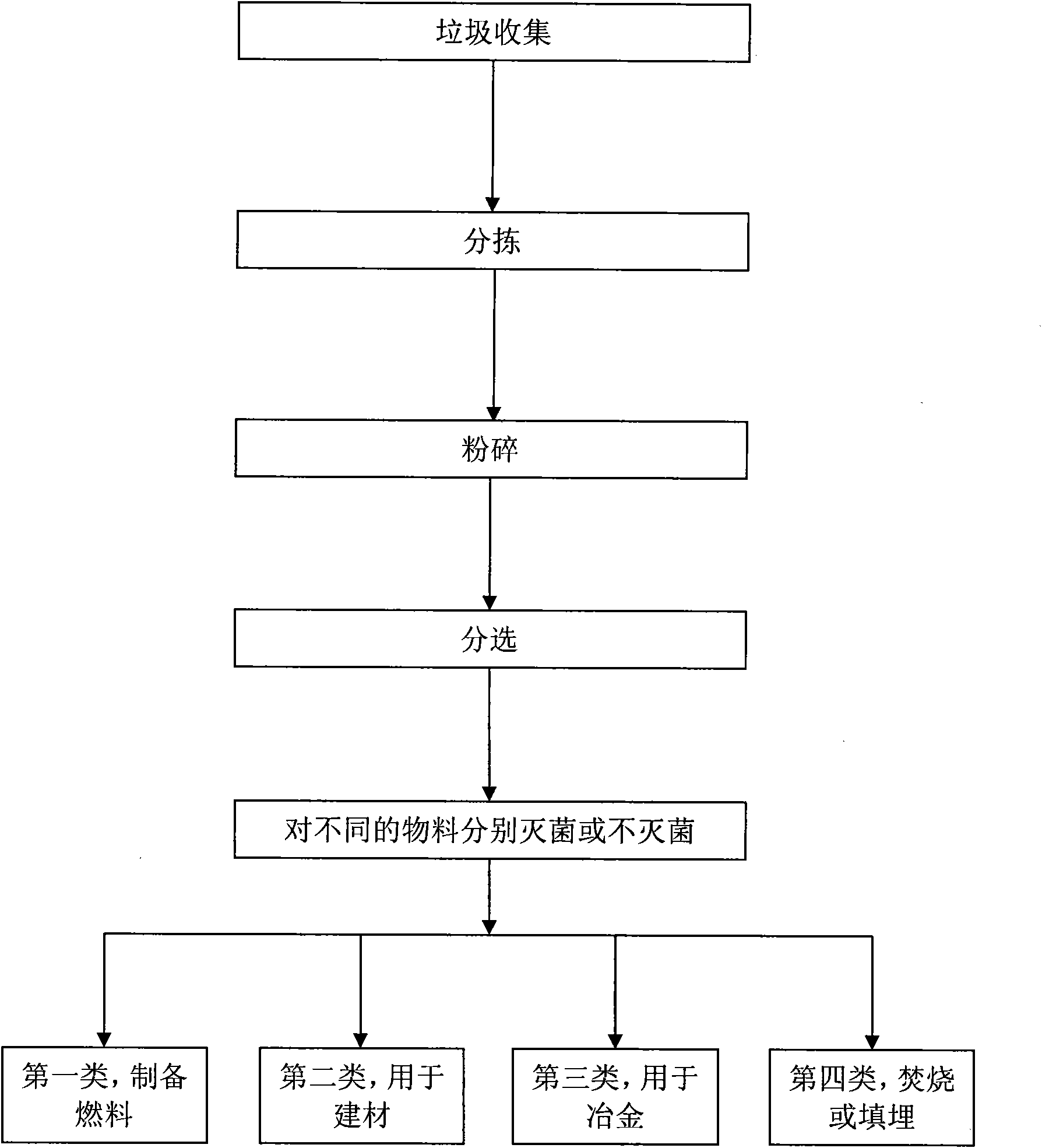

[0014] First, the medical waste is disposed of in the following ways:

[0015] (1) Garbage collection: use a closed collection method to collect medical waste;

[0016] (2) Sorting: Separate bulk materials and bulk materials that can be recycled and processed separately, collect and recycle them separately, and centrally process other materials;

[0017] (3) Pulverization: Under closed conditions, all the materials that are intensively processed are pulverized. According to the selected pulverization equipment, primary pulverization and secondary pulverization can be used for pulverization.

[0018] (4) Sorting: Mechanical sorting is carried out under closed conditions. According to the specific gravity and magnetic properties of the materials, they are divided into four categories. The first category is lighter materials, whose main components are fibers and other high molecular organic substances; It is a heavier material, and its main components are mineral substances such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com