Photodynamic sterilization fresh-keeping film for packaging ready-to-eat jellyfish

A fresh-keeping film and photodynamic technology, which is applied in the direction of anti-microbial preservation of food ingredients, food preservation, fruit and vegetable preservation, etc., to achieve the effects of extending shelf life, reducing sterilization costs, and good sterilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) After fully dissolving curcumin in absolute ethanol, add disodium EDTA solution and mix to obtain a photosensitizer complex solution with a final concentration of curcumin of 100 μmol / L and a final concentration of disodium EDTA of 0.02 wt %;

[0031] (2) Add chitosan to 1% acetic acid aqueous solution at 45-55°C, stir for 30 minutes until the chitosan is completely dissolved, and obtain a chitosan gel with a content of 1.5 wt%.

[0032] (3) Add 1mL photosensitizer complex solution to 5mL chitosan gel, add glycerin to make the concentration of glycerin in the obtained film liquid be 1wt%, stir for 4h and then ultrasonically degas for 10-15min;

[0033] (4) Pour the obtained film solution into the mold, let it stand for 1-1.5 hours, and then dry it at 35-45°C to form a film to obtain a photodynamic antibacterial fresh-keeping film;

[0034] (5) Pack the ready-to-eat jellyfish with the obtained photodynamic bacteria-reducing plastic wrap, and irradiate it with visible...

Embodiment 2

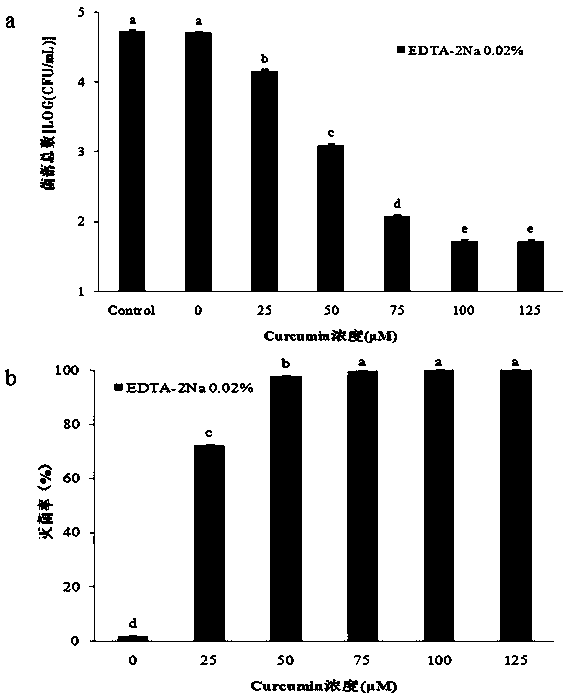

[0038] At 28°C, the photosensitizer complex solutions with the final concentrations of curcumin at 0, 25, 50, 75, 100, and 125 μmol / L and the final concentration of disodium EDTA at 0.02% were prepared respectively. According to the steps described in Example 1, the prepared photosensitizer complex solutions with different concentrations were respectively added to the chitosan gel, and a photodynamic antibacterial fresh-keeping film was prepared by solution casting. Meanwhile, a pure chitosan film without photosensitizer complex was prepared as a control.

[0039] Quantitative ready-to-eat jellyfish were weighed, and the experimental group was packaged with the prepared photodynamic antibacterial plastic wrap, while the control group was packaged with pure chitosan film. At 28°C, the samples were incubated in the dark for 30 min, and then placed at a distance of 20 cm from a blue LED light source with a wavelength of 425 nm for 30 min. Set up three parallels for each group. ...

Embodiment 3

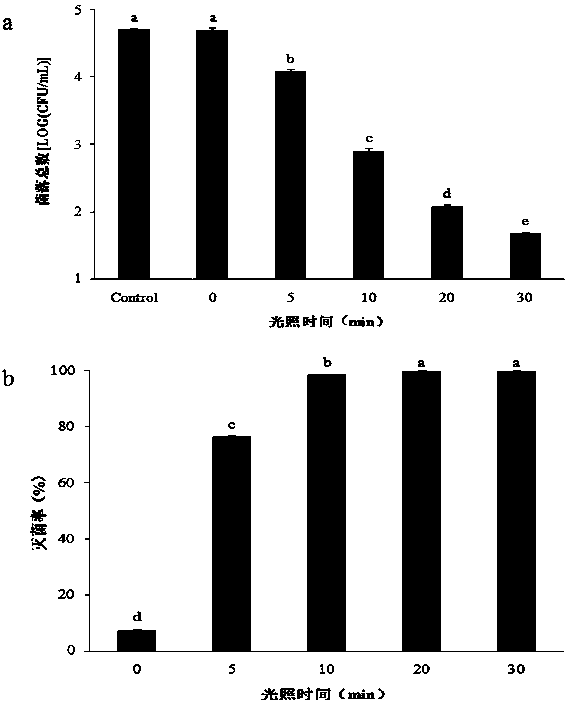

[0042]Under the condition of 28 ℃, according to the step preparation described in Example 1, the final concentration of curcumin is 100 μ mol / L, and the photosensitizer complex solution with disodium EDTA final concentration is 0.02%, and the photosensitizer complex solution prepared is added to Chitosan gel, by solution casting method to prepare photodynamic antibacterial preservation film. Meanwhile, a pure chitosan film without photosensitizer complex was prepared as a control.

[0043] Quantitative ready-to-eat jellyfish were weighed, and the experimental group was packaged with the prepared photodynamic antibacterial plastic wrap, while the control group was packaged with pure chitosan film. At 28°C, the samples were incubated in the dark for 30 min, and then placed at a distance of 20 cm from a blue LED light source with a wavelength of 425 nm for 0, 5, 10, 20, and 30 min respectively, and three parallels were set up for each group. The plate counting method was used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com