Preparation of quartz tube carried nanometer titanium dioxide film at its surface and use thereof

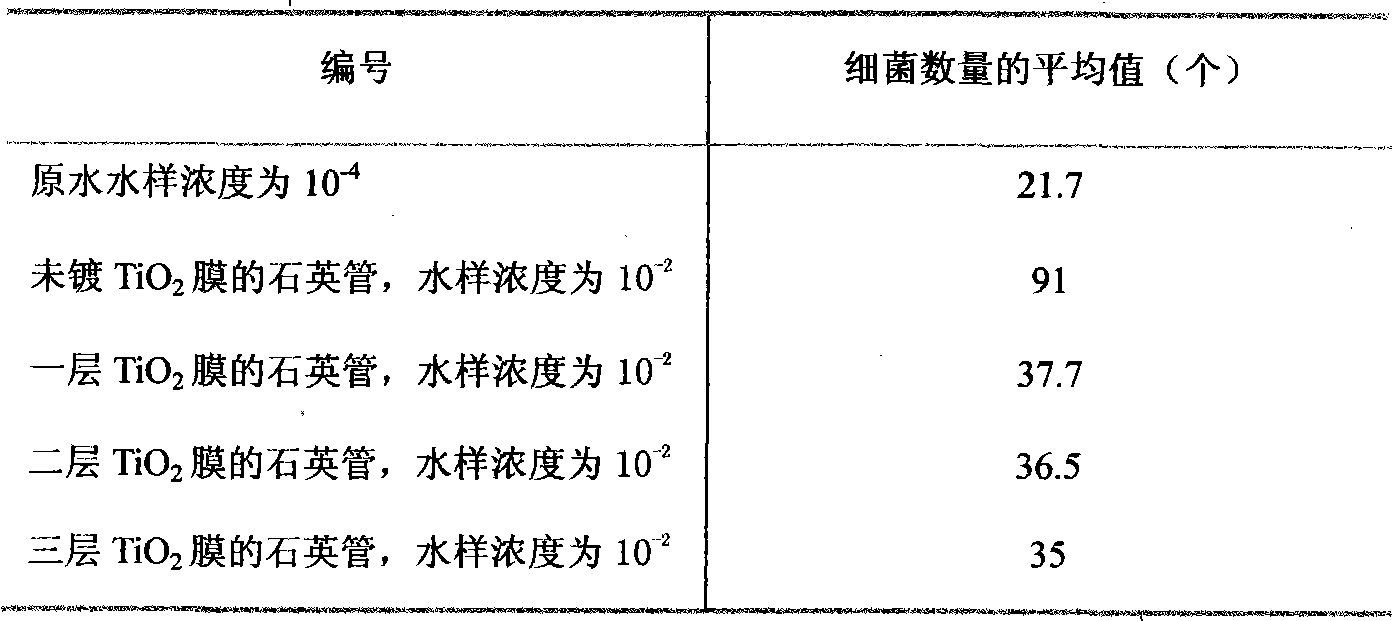

A nano-titanium dioxide, quartz tube technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems affecting the use of quartz tubes, etc., and achieve little change in sterilization rate and increase in sterilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] (1) TiO 2 Sol and TiO 2 and Fe(OH) 3 Preparation of mixed sols

[0015] Add 10ml of n-butyl titanate (analytically pure) into a beaker filled with 200ml of absolute ethanol, place it on a constant temperature (temperature 35-45°C) magnetic stirrer and stir at a low speed, and above the beaker is filled with 0.5mol / L nitric acid (HNO 3 ) acid burette, add 100ml drop by drop, you can get light blue TiO 2 Sol.

[0016] Add 100g of ferric chloride (FeCl 3 ), FeCl 3 Hydrolysis produces reddish-brown Fe(OH) 3 After the colloid was naturally cooled in the air, the precipitate was removed by filtration to obtain a pure reddish-brown colloid. By TiO 2 Sol and Fe(OH) 3 The sols are mixed in different volume ratios, such as 3:1, to obtain mixed sols.

[0017] (2) Coating nano-film or TiO doped with iron oxide on the outer surface of the quartz tube 2 film

[0018] Wash the quartz tube (300mm in length, 20mm in diameter) repeatedly with detergent and distilled water, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com