Pre-filled injector

A technology of prefilled syringes and needle tubes, applied in the field of syringes, can solve problems such as high cost and limited resources, and achieve the effect of reducing sterilization costs, solving resource constraints, and ensuring aseptic quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

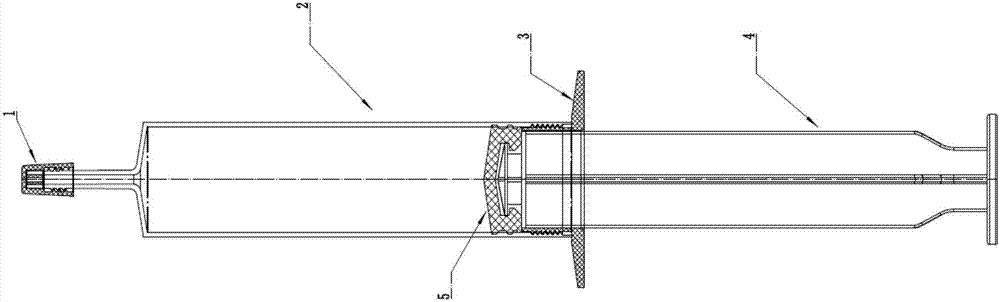

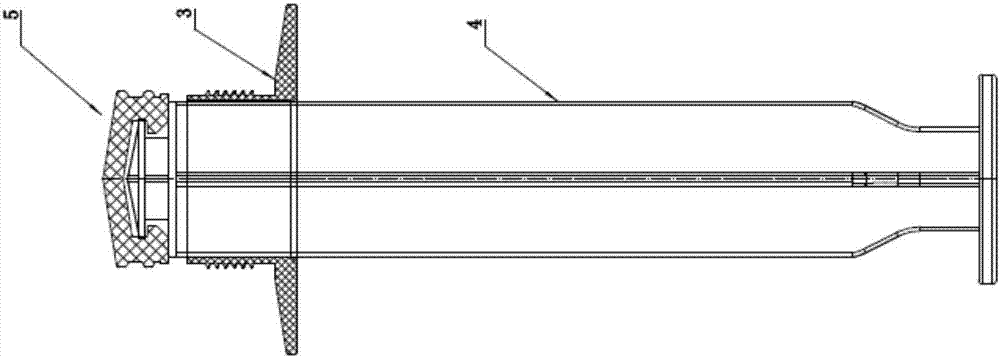

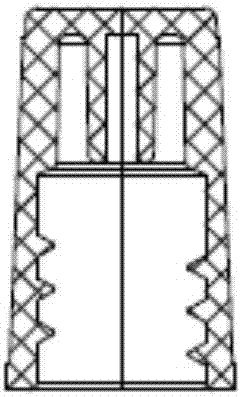

[0027] A prefilled syringe, comprising a cap 1, a needle tube 2, a handle 3, a push rod 4 and a piston 5, the end of the needle tube 2 near the handle 3 has an internal thread, the handle 3 has an inner hole, the front end of the handle 3 has an external thread, the needle tube 2 and the handle 3 are threadedly connected and assembled by rotation. The outer diameter of the push rod 4 matches the inner hole size of the handle 3. The cap 1 has internal threads, and the front end of the needle tube 2 has external threads. The cap 1 and the needle tube 2 are threaded connection, the outer diameter of the rear end of the piston 5 matches the inner diameter of the needle tube 2, and the inner hole size of the handle 3 matches the inner diameter of the needle tube 2. Piston 5 adopts high temperature resistant medical silicone material.

[0028] A preparation method of a prefilled syringe, the push rod 4 is passed through the inner hole of the handle 3, and then the top of the push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com