Method for biosynthesizing poly-beta-hydroxy butyric acid (PHB) by utilizing mixed methane-oxidizing bacteria

A hydroxybutyrate, methane oxidation technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms and other directions, can solve the problems of high PHB extraction cost, inactivation of methane-oxidizing bacteria, low PHB content, etc. The effect of growing cell density, reducing sterilization cost, and easy wall breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

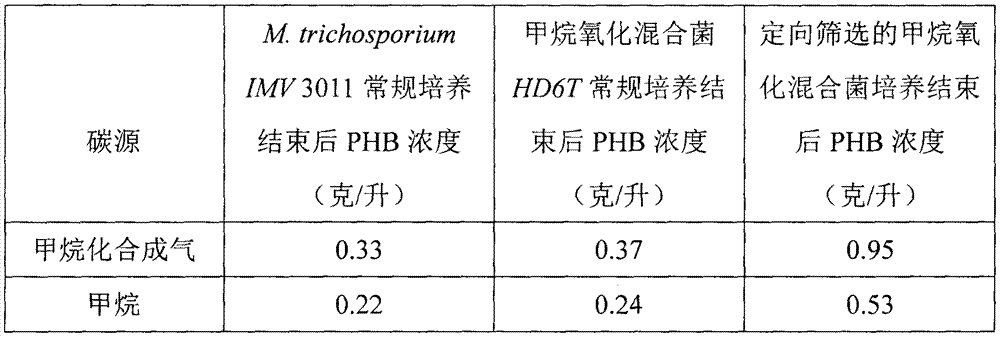

Examples

specific Embodiment approach 1

[0013] Specific embodiment 1: In this embodiment, the method for biosynthesizing poly-β-hydroxybutyrate by methane-oxidizing mixed bacteria is carried out according to the following steps:

[0014] The method for biosynthesizing poly-β-hydroxybutyrate by methane-oxidizing mixed bacteria is carried out in the following steps:

[0015] 1. Inoculate the mixed methane oxidizing bacteria liquid into the inorganic salt medium at an inoculation amount of 10%, and cultivate it on a shaker at 32°C and 180 rpm for 5 to 7 days, and replace it with vacuum every 12 hours during this period. fresh gas mixture;

[0016] 2. Then continue to cultivate for 10 to 15 days. During this period, use vacuum method to replace fresh air every 24 hours. After the cultivation, take half of the culture and insert it into fresh inorganic salt medium according to 50% of the inoculum to continue the domestication culture. , repeating this step 10 times to obtain methane oxidizing mixed bacteria that can gro...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the mass percent concentration of the mixed methane-oxidizing bacteria liquid is 30% to 50%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mixed gas in Step 1 and Step 3 is composed of methanation synthesis gas and air in a volume ratio of 1:1. Others are the same as in the first or second embodiment.

[0023] The methanation synthesis gas is a substitute natural gas; biomass is gasified to generate synthesis gas, which is purified and finally methanated to produce substitute natural gas with a methane content > 90%. The synthesis gas contains tar, sulfide, nitride, hydrogen Carbon monoxide, carbon dioxide and other impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com