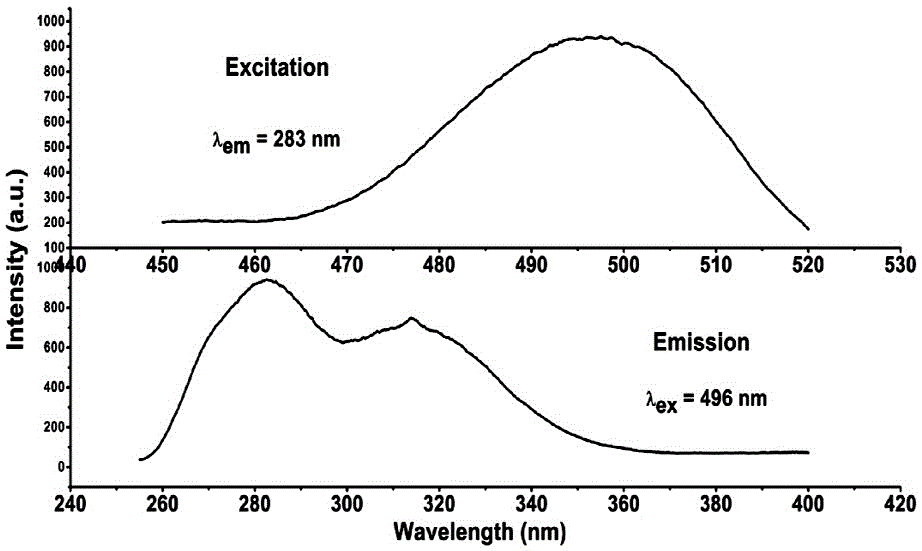

Silicate-based rare-earth ion doped visible-ultraviolet up-conversion luminescent material, and preparation method and application thereof

A technology of rare earth ions and luminescent materials, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of safety, hidden dangers, and inability to sterilize applications caused by operators, so as to reduce sterilization costs, low prices, and easy large-scale production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh yttrium nitrate, praseodymium nitrate, lithium carbonate and mesoporous silica according to the molar ratio of each element yttrium:praseodymium:lithium:silicon=1.836:0.012:0.07:0.918, mix and dissolve in distilled water, ultrasonically vibrate until uniformly dispersed, drop Add NaOH solution to make the pH of the solution 7, stir for 1 h, put it into the reaction kettle, heat it at 110 °C for 20 h, cool to room temperature, filter to take the filter cake, wash it with distilled water 5 times, and dry it at 60 °C for 6 h. The powder was calcined in a high-temperature box furnace, kept at 1100°C for 4 h, and then lowered to room temperature; taken out and ground to obtain a powdery up-conversion luminescent material.

[0040] The mesoporous silica was prepared by the following method: 240 mL of distilled water, 100 mL of absolute ethanol, 24 m of ammonia water and 5.2 g of cetyltrimethylammonium bromide were mixed evenly, and 7.28 mL of Tetraethyl orthosilicate, c...

Embodiment 2

[0042] Weigh yttrium nitrate, praseodymium nitrate, lithium carbonate and mesoporous silica according to the molar ratio of each element yttrium:praseodymium:lithium:silicon=1.836:0.012:0.07:0.918, mix and dissolve in distilled water, ultrasonically vibrate until uniformly dispersed, drop Add NaOH solution to make the pH of the solution 7, stir for 1.5 h, put it into a reaction kettle, heat it at 100 °C for 25 h, cool to room temperature, filter to take the filter cake, wash with distilled water 5 times, and dry at 60 °C for 6 h. The powder was calcined in a high-temperature box furnace, kept at 1000°C for 5 h, and then lowered to room temperature; taken out and ground to obtain a powdery up-conversion luminescent material.

Embodiment 3

[0044] Weigh yttrium nitrate, praseodymium nitrate, lithium carbonate and mesoporous silica according to the molar ratio of each element yttrium:praseodymium:lithium:silicon=1.836:0.012:0.07:0.918, mix and dissolve in distilled water, ultrasonically vibrate until uniformly dispersed, drop Add NaOH solution, stir for 1 h, then put it into the reaction kettle, heat it at 120°C for 18 h, cool to room temperature, filter to take the filter cake, wash it with distilled water for 5 times, dry at 60°C for 6 h, put the powder into a high temperature box furnace Calcined at 1200°C for 4.5 h, then lowered to room temperature; taken out and ground to obtain a powdery up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com