Sterilization device for bottle preforms

A sterilization device and bottle embryo technology, which is applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problems of high sterilization cost, large amount of fungicides, corrosion of carbon steel components, etc., and achieve good sterilization effect and low sterilization cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

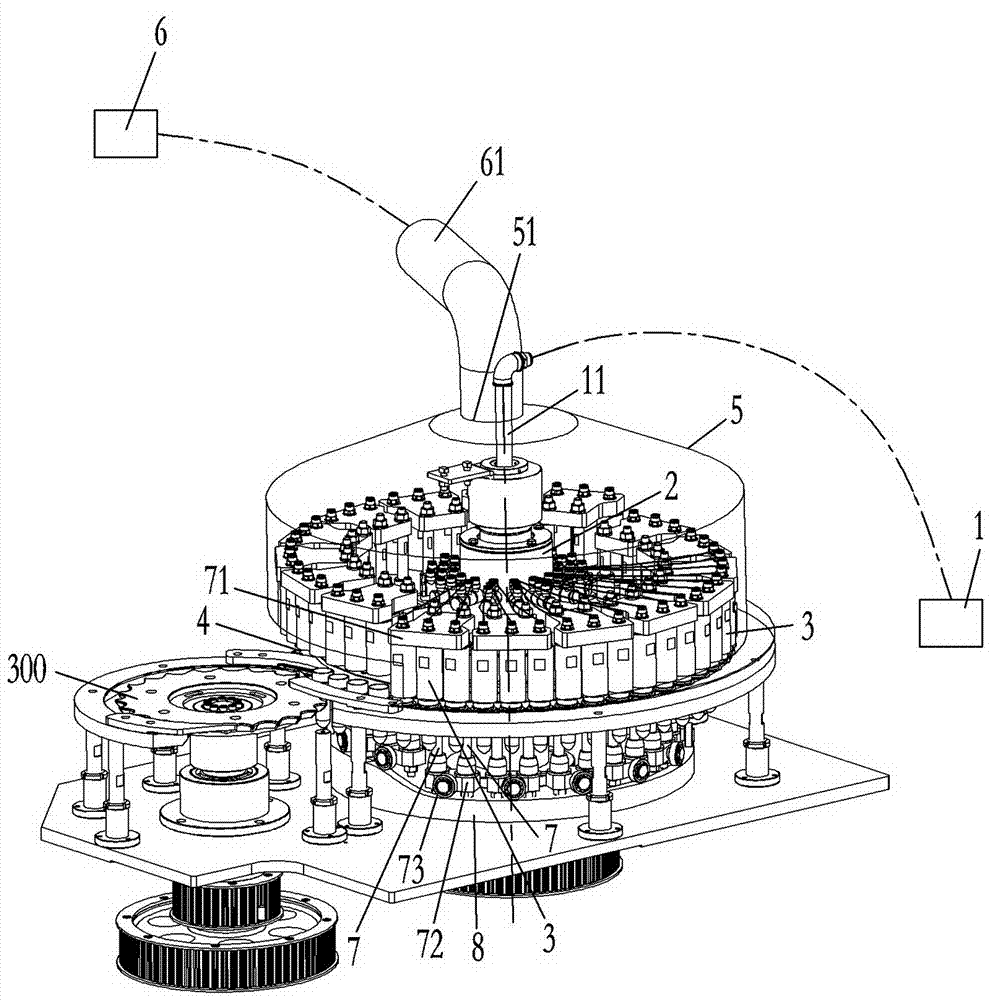

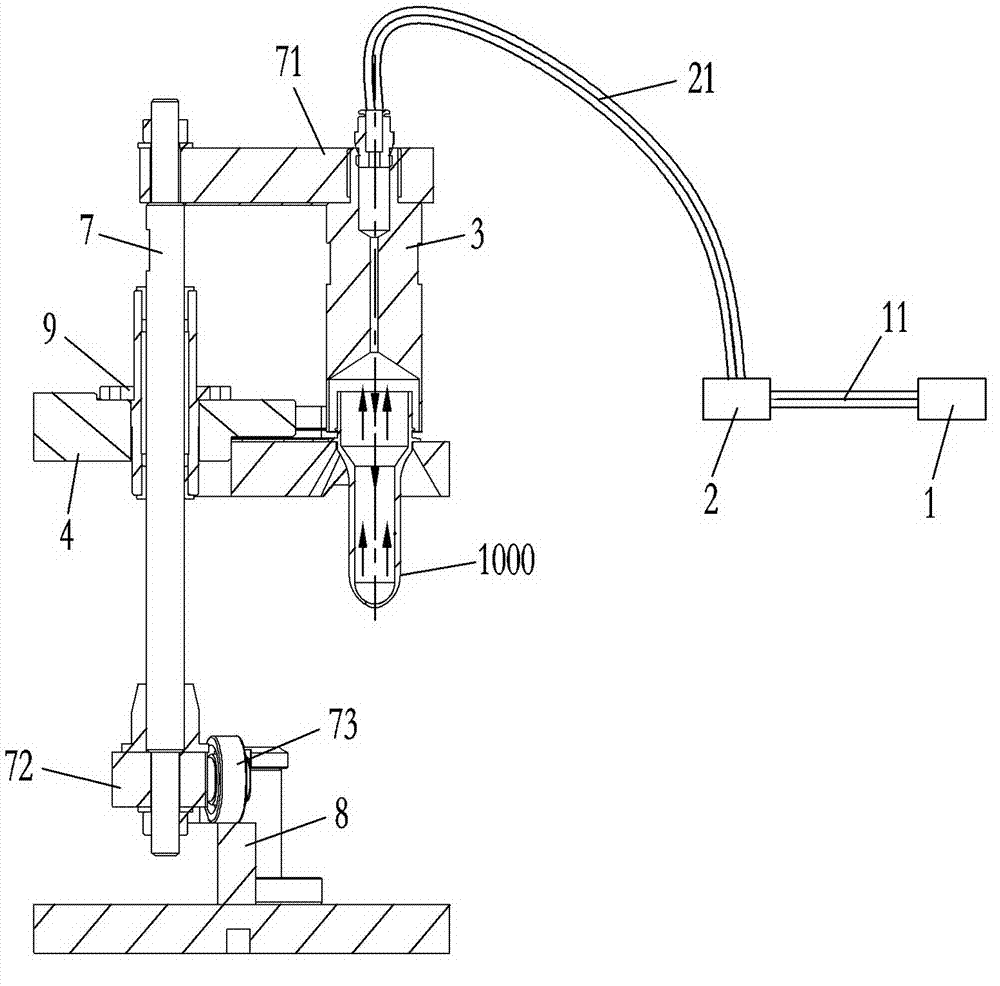

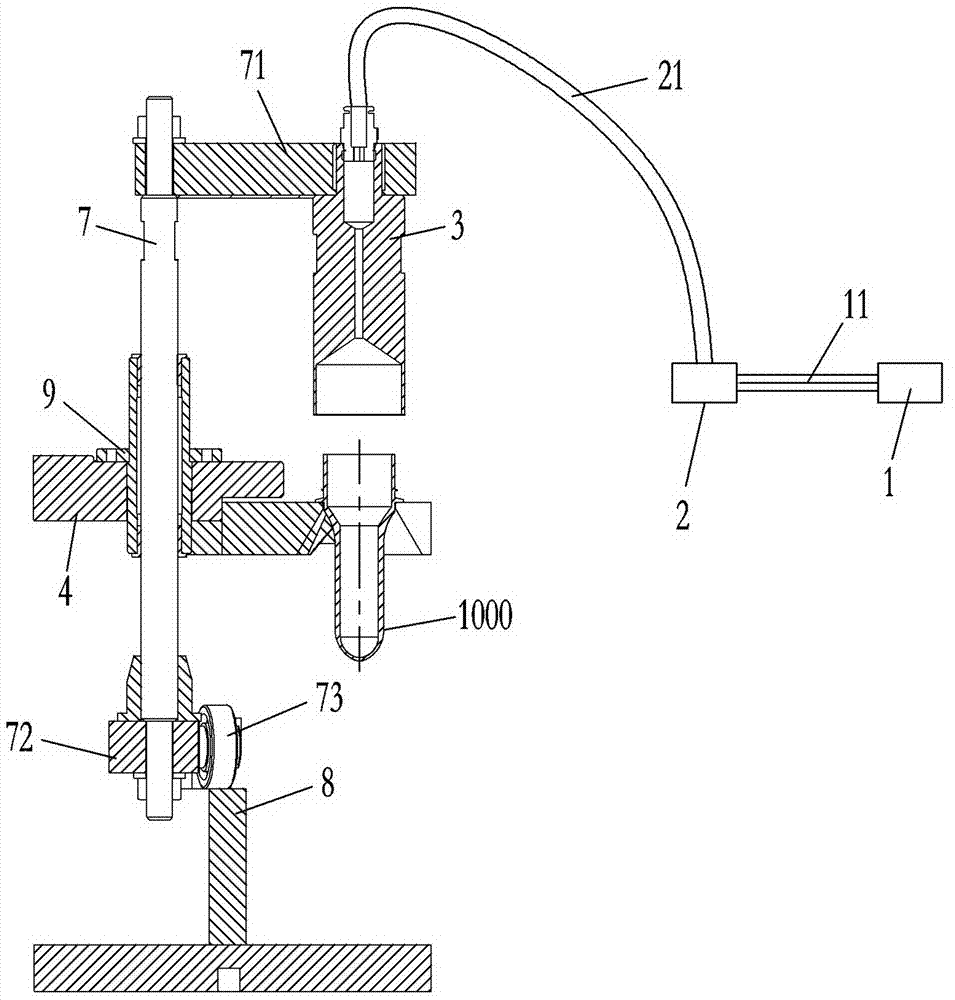

[0012] Such as Figures 1 to 4 As shown, the preform sterilization device includes a sterilizing agent processing unit 1, a plurality of nozzles 3 installed on the sterilizing star wheel 4 rotating with the sterilizing star wheel 4, and the gas outlet of the sterilizing steam distributor 2 and the air inlet end are respectively communicated with the sterilant treatment unit 1 and the nozzle 3 through the delivery pipes 11 and 21, so as to control the opening and closing of the pipeline between the sterilant treatment unit 1 and the nozzle 3 through the sterilizing steam distributor 2, When the embryo bottle 1000 is in the sterilizing area, the nozzle 3 is provided with a vaporized bactericide. The nozzle 3 is located directly above the preform 1000 captured by the sterilizing star wheel 4, and the vaporized bactericide can be sprayed into the inside of the preform 1000. The sterilizing star The periphery of the wheel 4 is provided with a recovery cover 5 that can cover the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com