Drilling fluid additive, drilling fluid and drilling method

A drilling fluid and additive technology, applied in wellbore/well components, chemical instruments and methods, earth-moving drilling, etc., can solve the problems of inability to match zeta potential, low zeta potential value, poor stabilization effect, etc. The effect is good, the composition is simple, and the drilling efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

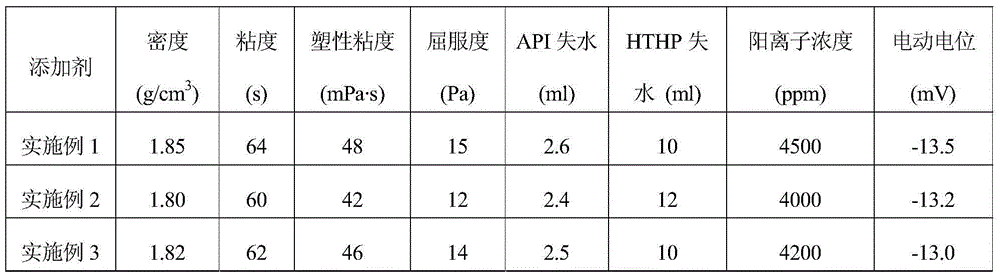

Examples

Embodiment 1

[0026] To the mixing water (Cl - content <6000mg / l) by adding a small amount of NaOH and decalcifying agent CPN to make the pH 9-10, add bentonite for drilling fluid according to the ratio of 90kg bentonite per cubic meter of water (1000L), stir, cycle and age for later use .

[0027] 2. Drilling fluid additives

[0028] The first additive comprises 3 parts of cationic inhibitor CPI and 26 parts of cationic coating agent CPH-26 according to the weight ratio;

[0029] The second additive comprises 8 parts of cationic inhibitor CPI, 29 parts of cationic coating agent CPH-29 parts and cationic fluid loss reducer CPF-18 parts according to the weight ratio;

[0030] The third additive (i.e. drilling fluid additive) includes the following components according to the weight ratio: 10 parts of cationic inhibitor CPI, 26 parts of cationic coating agent CPH-26 parts, cationic fluid loss reducer CPF-18 parts, cationic fluid loss reducer 2 parts of agent C...

Embodiment 2

[0032] 1. Bentonite slurry

[0033] Add a small amount of NaOH and calcium remover CPN to the slurry preparation water to make the pH 9-10, add bentonite for drilling fluid at the ratio of 100kg bentonite per cubic meter of water, stir, cycle and age before use.

[0034] 2. Drilling fluid additives

[0035] The first additive comprises 2 parts of cationic inhibitor CPI and 28 parts of cationic coating agent CPH-2 according to the weight ratio;

[0036] The second additive comprises 6 parts of cationic inhibitor CPI, 10 parts of cationic coating agent CPH-2 and 110 parts of cationic fluid loss reducer CPF according to the weight ratio;

[0037] The third additive includes the following components according to the weight ratio: 6 parts of cationic inhibitor CPI, 28 parts of cationic coating agent CPH, 110 parts of cationic fluid loss reducer CPF, 3 parts of cationic fluid loss reducer CPF, cationic 2 parts of blocking agent CPA.

Embodiment 3

[0039] 1. Bentonite slurry

[0040] Add a small amount of NaOH and calcium remover CPN to the slurry preparation water to make the pH 9-10, add bentonite for drilling fluid at a ratio of 80kg bentonite per cubic meter of water, stir, cycle and age before use.

[0041] 2. Drilling fluid additives

[0042] The first additive comprises 4 parts of cationic inhibitor CPI and 24 parts of cationic coating agent CPH-2 according to the weight ratio;

[0043] The second additive includes 10 parts of cationic inhibitor CPI, 28 parts of cationic coating agent CPH-28 parts and cationic fluid loss reducer CPF-16 parts according to the weight ratio;

[0044] The third additive includes the following components according to the weight ratio: 15 parts of cationic inhibitor CPI, 24 parts of cationic coating agent CPH, 14 parts of cationic coating agent CPH, 15 parts of cationic fluid loss reducer CPF, cationic 1 part of fluid loss reducer CPF, 1 part of cationic plugging agent CPA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com