Electrophoresis display particles as well as preparation method and application thereof

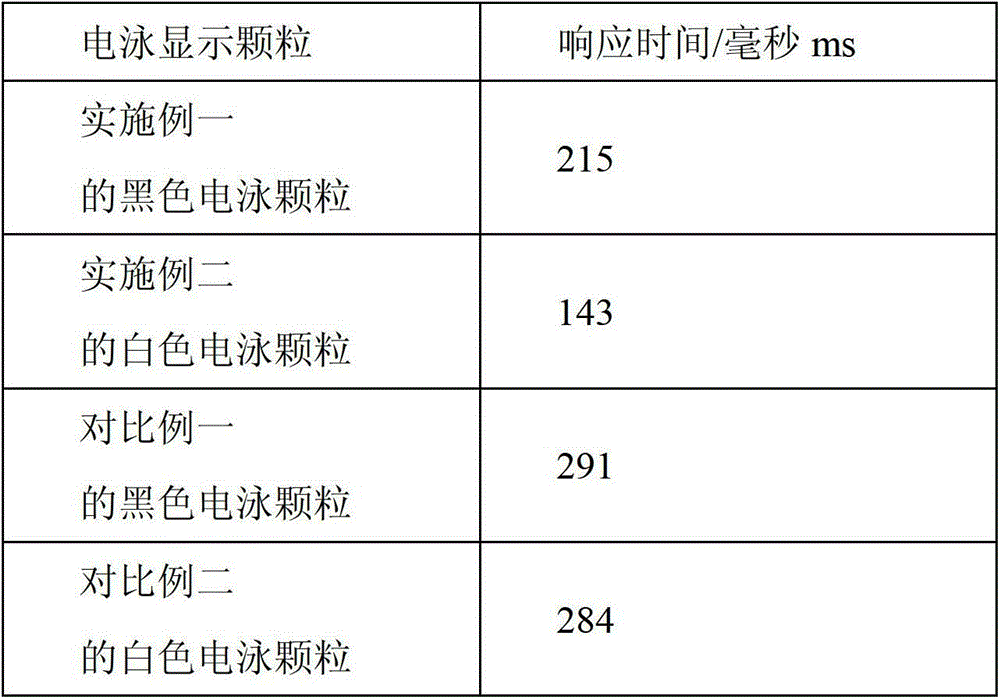

An electrophoretic display and particle technology, which is applied in chemical instruments and methods, optics, instruments, etc., can solve the problems of low content of charged functional groups on the surface, insufficient chargeability, and inconvenient operation, so as to improve dispersion and response time The effect of shortening and enhancing the charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An electrophoretic display particle, and an electrophoretic display liquid containing the electrophoretic display particle, the preparation steps are as follows:

[0037] (1) Preparation of color paste: Weigh an appropriate amount of iron black, add it to 1000ml of water, stir and disperse at 400 rpm for 20 minutes, and make a color paste with a pigment particle content of 7.1wt%;

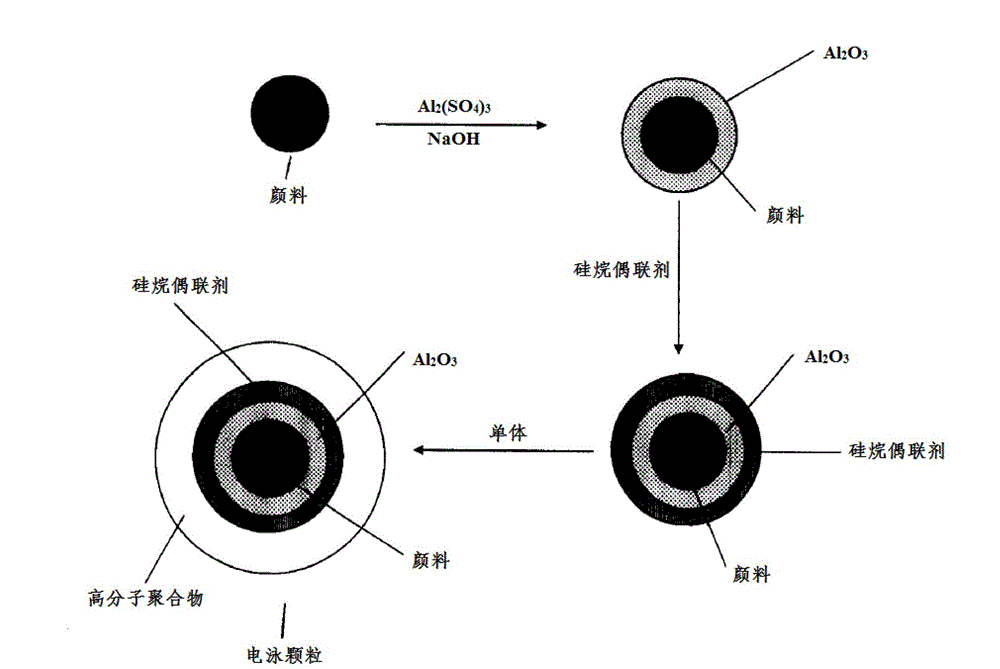

[0038] (2) Coated aluminum oxide film: keep the temperature of the reaction system at 30°C, and add 0.1mol / L Al dropwise to the color paste in step 1) at the same time 2 (SO 4 ) 3 solution and 0.5mol / L NaOH solution; adjust Al 2 (SO 4 ) 3 solution and NaOH solution to keep the pH value of the reaction system at 4.5~5.0; after continuous dropping for 30 minutes, age for 120 minutes, cool to room temperature, centrifuge and wash to obtain Al-coated 2 o 3 Composite pigment particles A.

[0039] (3) Coupling: Take an appropriate amount of the composite pigment particle A prepared in step ...

Embodiment 2

[0043] An electrophoretic display particle, and an electrophoretic display liquid containing the electrophoretic display particle, the preparation steps are as follows:

[0044] (1) Preparation of color paste: Weigh an appropriate amount of titanium dioxide, add it to 1000ml of water, stir and disperse at 400 rpm for 20 minutes, and make a color paste with a pigment particle content of 23.1wt%;

[0045] (2) Coated aluminum oxide film: keep the temperature of the reaction system at 70°C, and add 0.5mol / L Al dropwise to the color paste in step 1) at the same time 2 (SO 4 ) 3 solution and 2mol / L NaOH solution; adjust Al 2 (SO 4 ) 3 solution and NaOH solution to keep the pH value of the reaction system at 5~7.5; after continuous dropping for 180 minutes, age for 240 minutes, cool to room temperature, centrifuge and wash to obtain coated Al 2 o 3 Composite pigment particles A.

[0046] (3) Coupling: Take an appropriate amount of the composite pigment particle A prepared in s...

Embodiment 3

[0050] An electrophoretic display particle, and an electrophoretic display liquid containing the electrophoretic display particle, the preparation steps are as follows:

[0051] (1) Preparation of color paste: Weigh an appropriate amount of copper chrome black, add it to 1000ml of water, stir and disperse at 400 rpm for 20 minutes, and make a color paste with a pigment particle content of 15wt%;

[0052] (2) Coated aluminum oxide film: keep the temperature of the reaction system at 60°C, and add 0.2mol / L Al(NO) dropwise to the color paste in step 1) at the same time 3 solution and 0.8mol / L NaOH solution; adjust Al(NO) 3 solution and NaOH solution to keep the pH value of the reaction system at 5.0~5.5; after continuous dropping for 120 minutes, aging for 200 minutes, cooling to room temperature, centrifuging and washing, the coated Al 2 o 3 Composite pigment particles A.

[0053] (3) Coupling: Mix the composite pigment particle A prepared in step (2) with 800ml ethanol and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com