Preparation method and application of quaternary ammonium salt-N-halamine nano antibacterial fibers

A nano-antibacterial fiber, quaternary ammonium salt technology, applied in fiber treatment, plant fiber, animal fiber and other directions, can solve the problems of limiting the wide application of tree cotton fiber, poor cohesion, difficult to form strips, etc. Long-lasting, not easily reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

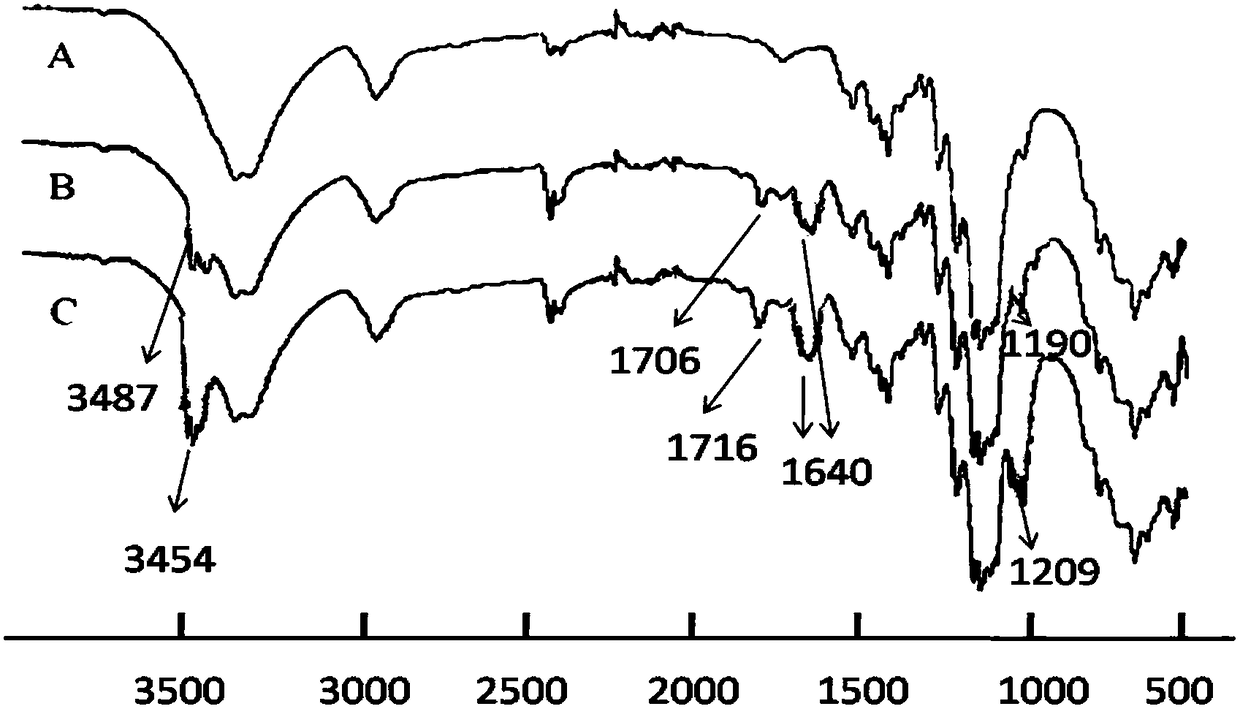

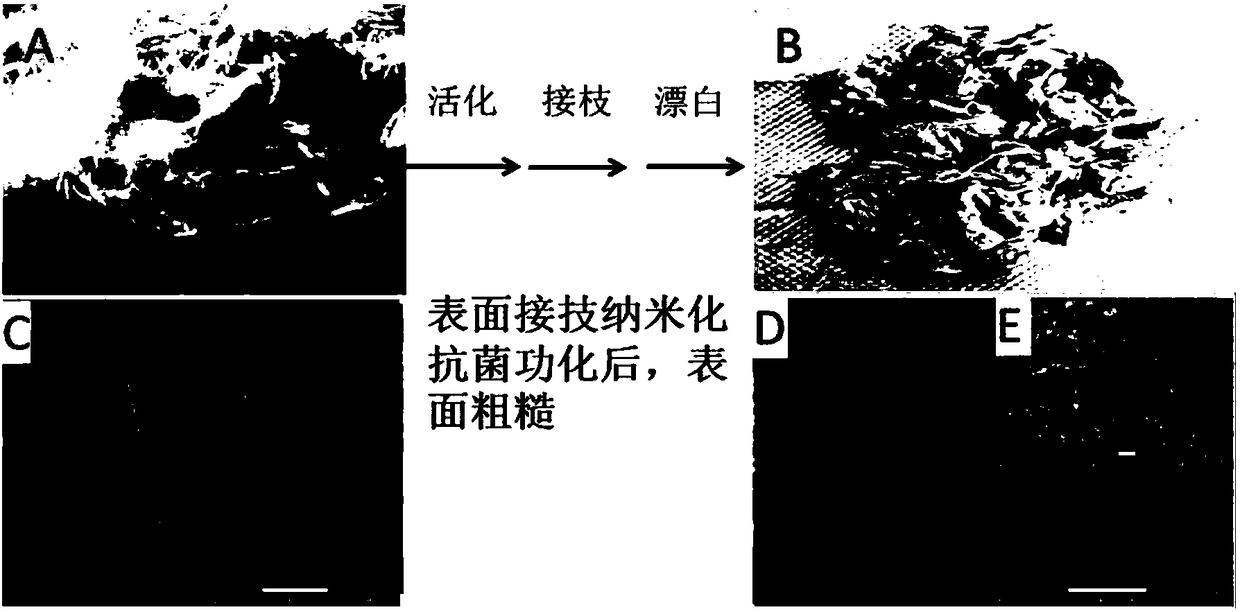

[0047] The preparation method of quaternary ammonium salt-N-halamine type nano antibacterial fiber of the present invention comprises the steps:

[0048] A: Soak the mixed fibers of tree cotton fiber and cotton fiber in the ethylenediamine solution with a mass fraction of 70% at a bath ratio of 1:55, heat the water bath to 35°C, and wash the tree with ethanol and purified water alternately after heating for 3 hours Cotton fiber 2 times, add epichlorohydrin to the cotton fiber at a bath ratio of 1:3, and add a sodium hydroxide solution with a molar concentration of 0.005mol / L at a bath ratio of 1:6, and stir at 28°C React for 8 hours, then wash with purified water, put in an oven and dry at 55°C to obtain activated epoxy fibers;

[0049] B: Mix the epoxy fiber in step A with the polyamino polymer solution with a volume fraction of 8% at a bath ratio of 1:45, heat to 65°C, stir and react for 3.5 hours, and then alternately wash the reaction with ethanol and purified water The p...

Embodiment 2

[0062] The preparation method of quaternary ammonium salt-N-halamine type nano antibacterial tree cotton fiber of the present invention comprises the steps:

[0063] A: Soak the cotton fiber in the ethylenediamine solution with a mass fraction of 72% at a bath ratio of 1:57, heat it in a water bath to 37°C, and wash the cotton fiber three times alternately with ethanol and purified water after heating for 3.3 hours. Add epichlorohydrin to the cotton fiber at a bath ratio of 1:3.4, and add a sodium hydroxide solution with a molar concentration of 0.007mol / L at a bath ratio of 1:6.3, stir and react at 28.5°C for 8.4h, and then Wash it with purified water, put it into an oven and dry it at 57°C to obtain activated epoxy cotton fiber;

[0064] B: Mix the epoxy cotton fiber in step A with the polyamino polymer solution with a volume fraction of 8.6% at a bath ratio of 1:48, heat to 68°C, stir for 3.8 hours, and then use ethanol and purified water alternately washing the reaction p...

Embodiment 3

[0077] The preparation method of quaternary ammonium salt-N-halamine type nano antibacterial hemp fiber of the present invention comprises the steps:

[0078]A: Soak the hemp fiber in a ethylenediamine solution with a mass fraction of 73% at a bath ratio of 1:60, heat it in a water bath to 38°C, and wash the hemp fiber twice with ethanol and purified water alternately after heating for 3.7 hours. Add epichlorohydrin to the fiber at a bath ratio of 1:3.7, and add a sodium hydroxide solution with a molar concentration of 0.008mol / L at a bath ratio of 1:6.6, stir and react at 29°C for 8.8 hours, and then use purified water Clean, put into oven and dry at 59 ℃, obtain the activated epoxy hemp fiber;

[0079] B: Mix the epoxy hemp fiber in step A with the polyamino polymer solution with a volume fraction of 9% at a bath ratio of 1:50, heat to 69°C, stir for 4.2 hours, and then alternately wash with ethanol and purified water The reaction product is then dried at 50°C to obtain pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com