Preparation method of sodium hyaluronate gel

The technology of sodium hyaluronate and gel is applied in the fields of biomedicine, medical cosmetology, and cosmetic surgery, which can solve the problems of increased difficulty in use, increased extrusion pressure, uneven stress surface, etc., and achieves excellent biocompatibility, The effect of strengthening the mechanical strength and delaying the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

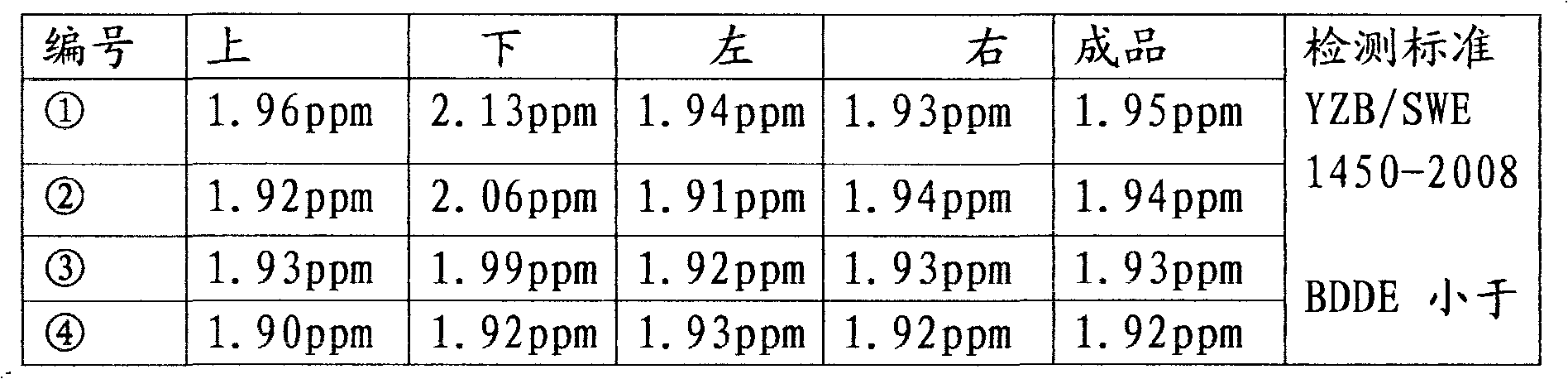

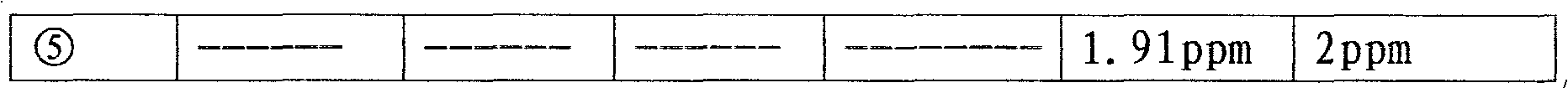

Image

Examples

Embodiment 1

[0030] Step 1), in the alkaline solution with a pH value of 10, add 0.01% (weight) of cross-linking agent after shaking and dissolving, then add 10% (weight) of high-purity sodium hyaluronate raw material, at room temperature 25 ° C, In an environment where the number of 0.5um particles is less than 3500, the temperature is controlled at 27°C, 3800 rpm high-speed rotation and stirring for 30 minutes, and then heated at a constant temperature of 50°C to obtain a sodium hyaluronate molded product;

[0031] Step 2), at room temperature 25°C, in an environment where the number of 0.5um particles is controlled to be less than 3500, cut the molded object into 1cm 3 The lumps are put into the solution of normal saline and phosphate ratio, the mass ratio of the lumps to the solution is controlled at 1:1000, so that the contact area between the lumps and the solution is the same, and the contact time is controlled at 20 hours. Sodium hyaluronate gel;

[0032] Wherein, the NaCl of desc...

Embodiment 2

[0038] Step 1) The pH value of the alkaline solution is 11, the high-purity sodium hyaluronate raw material is 15% (weight), the temperature is controlled at 28°C, and the high-speed rotation is stirred at 4000 rpm, and the others are the same as in Example 1;

[0039] In step 2), the molding is cut into 1cm 3 The lump, contact time is controlled at 21 hours, and other is with embodiment 1;

[0040] Step 3) 50 mesh stainless steel screens are used for net screening, and others are with embodiment 1;

[0041] Step 4) is the same as embodiment 1;

[0042] Step 5) stirring speed is 3800 rev / min, other is with embodiment 1;

[0043] Step 6) is the same as in Example 1.

Embodiment 3

[0045] Step 1) The pH value of the alkaline solution is 12, the high-purity sodium hyaluronate raw material is 20% (by weight), the temperature is controlled at 29 ° C, and the high-speed rotation is stirred at 4200 rpm, and the others are the same as in Example 1;

[0046] In step 2), the molding is cut into 2cm 3 The lump, contact time is controlled at 22 hours, and other is with embodiment 1;

[0047] Step 3) 80 mesh stainless steel screens are used for net screening, and others are with embodiment 1;

[0048] Step 4) is the same as embodiment 1;

[0049] Step 5) stirring speed is 3900 rev / min, other is with embodiment 1;

[0050] Step 6) is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com