Long after-glow phosphorescent material and preparation method thereof

A technology of luminescent materials and phosphates, applied in luminescent materials, chemical instruments and methods, etc., to achieve the effects of low production cost, good stability and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing a phosphate long-lasting luminescent material, characterized in that it includes the following steps: 1) Accurately weigh the carbonates, oxides or phosphates of the corresponding elements according to the stoichiometric ratio according to the composition of the above chemical formula Raw materials; 2) Mix and grind the raw materials in step 1) evenly, and directly calcinate at 800-1200°C for 2-12 hours in a reducing atmosphere, or pre-calcine at 300-800°C for 2-6 hours, and cool to room temperature. After re-grinding, calcining at 800-1200°C for 2-12 hours in a reducing atmosphere, cooling to room temperature naturally, and then grinding the resulting product to obtain the final product.

[0026] According to the above scheme, the preferred temperature for calcination of the raw materials is 950-1100°C.

[0027] According to the above scheme, the preferred time for the calcination of the raw materials is 3 to 6 hours.

[0028] According to the a...

Embodiment 1

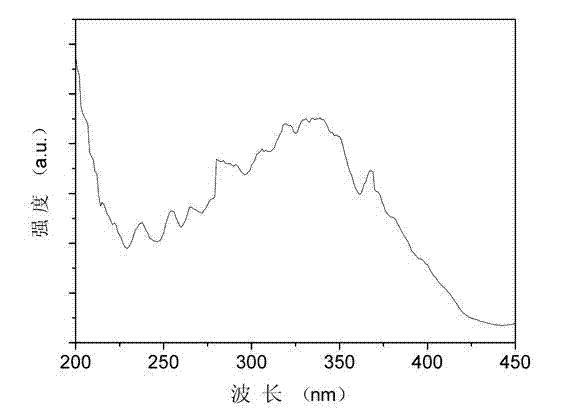

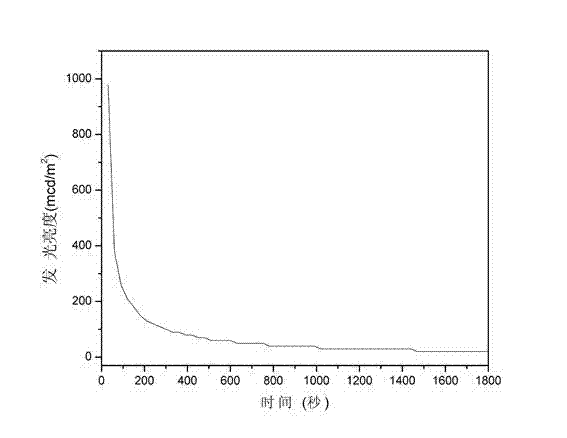

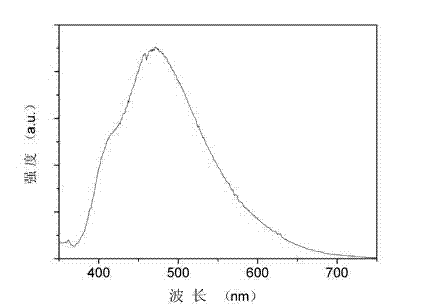

[0031] Raw material is CaCO 3 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure), Eu 2 o 3 (99.99%) and Gd 2 o 3 (99.99%), the molar ratio between them is 2.91:2:0.015:0.03, accurately weigh each raw material and mix and grind evenly, put it in a crucible, put it into a high-temperature furnace, and put it in a 5% H 2 / 95%N 2 Calcined at 1100 °C for 4 hours in a reducing atmosphere, cooled naturally to room temperature, and ground to obtain a phosphate long-lasting luminescent material Ca 2.91 (PO 4 ) 2 : 0.03Eu 2+ , 0.06Gd 3+ , the main phase is Ca 3 (PO 4 ) 2 . Figure 1a and Figure 1b Excitation (a) and emission (b) spectra of the long-lasting luminescent materials provided in this example, respectively; figure 2 The afterglow decay curve of the long afterglow luminescent material provided in this embodiment.

Embodiment 2

[0033] The raw material is SrCO 3 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure), Eu 2 o 3 (99.99%) and Gd 2 o 3 (99.99%), the molar ratio between them is 2.91:2:0.015:0.03, accurately weigh each raw material and mix and grind evenly, put it in a crucible, put it into a high-temperature furnace, and put it in a 5% H 2 / 95%N 2 Calcined at 1100 °C for 4 hours in a reducing atmosphere, cooled naturally to room temperature, and ground to obtain the phosphate long-lasting luminescent material Sr 2.91 (PO 4 ) 2 : 0.03Eu 2+ , 0.06Gd 3+ , the main phase is Sr 3 (PO 4 ) 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com